Advanced treatment and recycling system for copper smelting acidic wastewater

A pickling wastewater and advanced treatment technology, which is applied in metallurgical wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems that it is difficult to meet the requirements of environmental protection and clean production, and achieve the alleviation of the contradiction between supply and demand of water resources , good treatment effect, and the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

[0025] It should be noted that, unless otherwise specified, the technical terms or scientific terms used in this application shall have the usual meanings understood by those skilled in the art to which the present invention belongs.

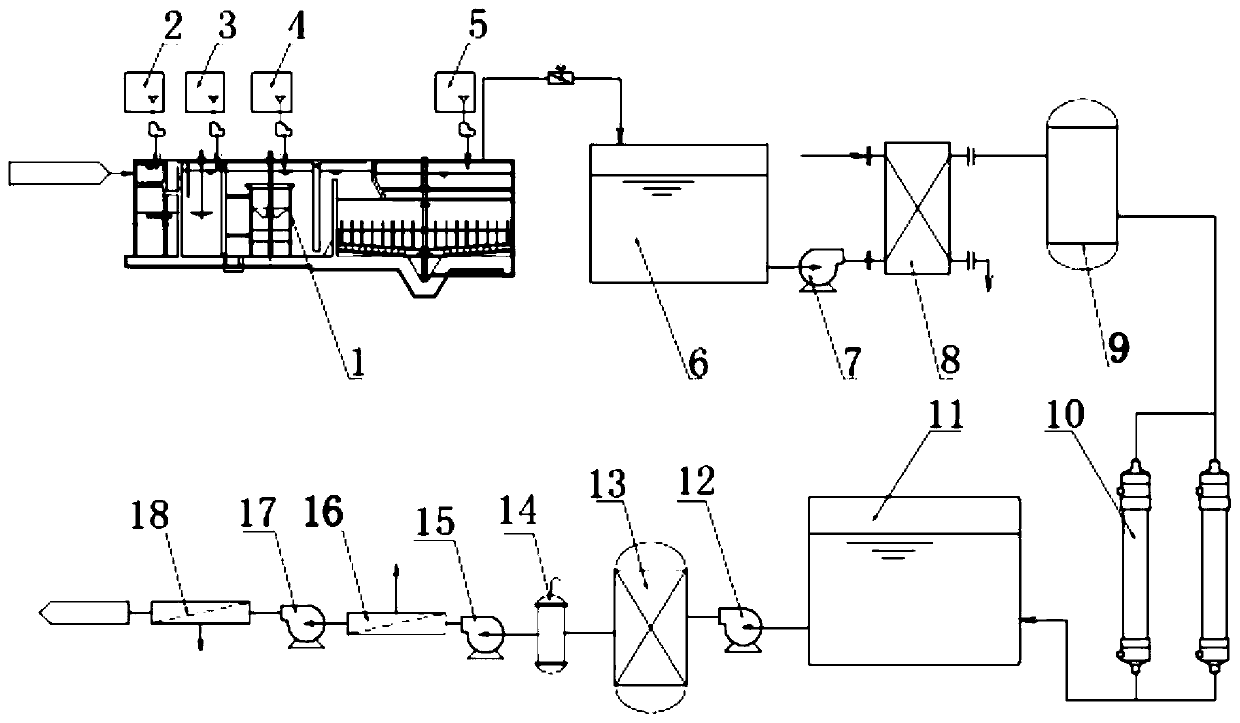

[0026] Such as figure 1 As shown, this embodiment provides an advanced treatment and reuse system for copper smelting pickling wastewater, including an integrated sedimentation device 1, a raw water tank 6, a raw water pump 7, a plate heat exchange device 8, and a multimedia filter 9 connected in sequence , ultrafiltration membrane system 10, intermediate water tank 11, booster pump...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com