Hyperbranched polyamide for high-temperature nylon processing as well as preparation method and application thereof

A technology of hyperbranched polyamide and nylon, which is applied in the field of hyperbranched polyamide for high temperature nylon processing and its preparation, can solve the problem of difficulty in preparing nylon-glass fiber composite materials, cannot solve high temperature resistant nylon processing, and affects the mechanical properties of composite materials, etc. problems, to achieve the effect of unaffected mechanical properties, significantly improved fluidity, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

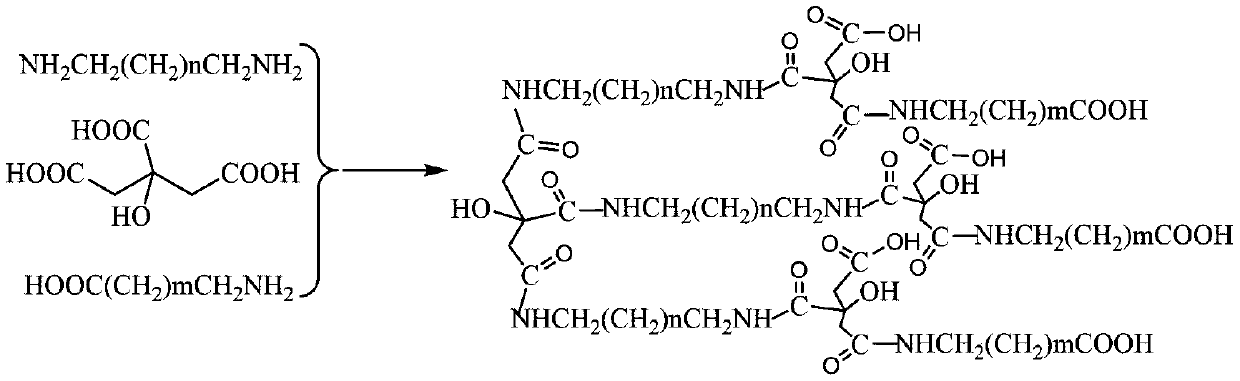

[0036] Embodiment 1 A kind of hyperbranched polyamide for high temperature nylon processing, the preparation method is as follows:

[0037] 1.35mol citric acid, 1.0mol hexamethylenediamine, 0.5mol 5-aminovaleric acid, 2.32g methylbenzenesulfonic acid, 300g toluene, 48g dioxane were added to the In a four-necked flask with a thermometer, heat it to 110°C under nitrogen protection, and stir and react at 110°C for 20 hours. At this time, the water separator is anhydrous, and the water-carrying agent toluene and dioxane are removed in a vacuum while it is hot. Take out, After cooling, a hyperbranched polyamide (referred to as HBP-1) is obtained, and its number-average molecular weight is 1300 g / mol as measured by GPC.

[0038] Mix 2.0g of HBP-1, 500g of nylon-66, and 510g of glass fiber evenly, process and granulate through a screw extruder at 280°C to obtain a high-performance nylon 66-glass fiber composite material with a smooth surface, and the performance of the composite mate...

Embodiment 2

[0039] Embodiment 2 A kind of hyperbranched polyamide for high temperature nylon processing, the preparation method is as follows:

[0040] 1.0mol of trimesic acid, 1.02mol of 1,7-heptanediamine, 0.3mol of δ-valerolactam, 6.63g of phosphoric acid (a liquid with a concentration of 85wt%) and 663g of xylene were added to a condenser, agitator, In the four-necked flask with water separator and thermometer, heat to 150°C under nitrogen protection condition, and stir and react at 150°C for 10 hours. After cooling, a hyperbranched polyamide (referred to as HBP-2) is obtained, and its number-average molecular weight is 15000 g / mol as measured by GPC.

[0041] Mix 20.0g of HBP-2, 500g of nylon-66, and 520g of glass fiber evenly, process and granulate through a screw extruder at 280°C to obtain a high-performance nylon 66-glass fiber composite material with a smooth surface, and the performance of the composite material As shown in Table 1.

Embodiment 3

[0042] Embodiment 3 A kind of hyperbranched polyamide for high temperature nylon processing, the preparation method is as follows:

[0043]Add 1.0mol trimellitic acid, 1.02mol 4,4'-diaminodiphenylmethane, 0.3mol enantholactam, 6.05g tetra-n-butyl titanate, 500g xylene, and 105g dimethylformamide into the container In a four-necked flask with a condenser, agitator, water separator and thermometer, heat to 140°C under nitrogen protection, and stir and react at 140°C for 15 hours. At this time, no water is formed in the water separator. Aqueous xylene was taken out and cooled to obtain a hyperbranched polyamide (referred to as HBP-3), and its number average molecular weight was 19000 g / mol as measured by GPC.

[0044] Mix 10.0g of HBP-3, 500g of nylon-66, and 510g of glass fiber evenly, process and granulate through a screw extruder at 280°C to obtain a high-performance nylon 66-glass fiber composite material with a smooth surface, and the performance of the composite material A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com