Method and apparatus for hydrotreating waste plastics

A technology for hydrogenation treatment and waste plastics, which is applied in the direction of hydrogenation treatment process, hydrocarbon oil treatment, hydrocarbon oil treatment products, etc. It can solve the problems of insufficient catalyst wetting, low yield of liquid products, high cracking initiation temperature, etc., and achieve Excellent hydroisomerization effect, complete removal of impurities, and good cracking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

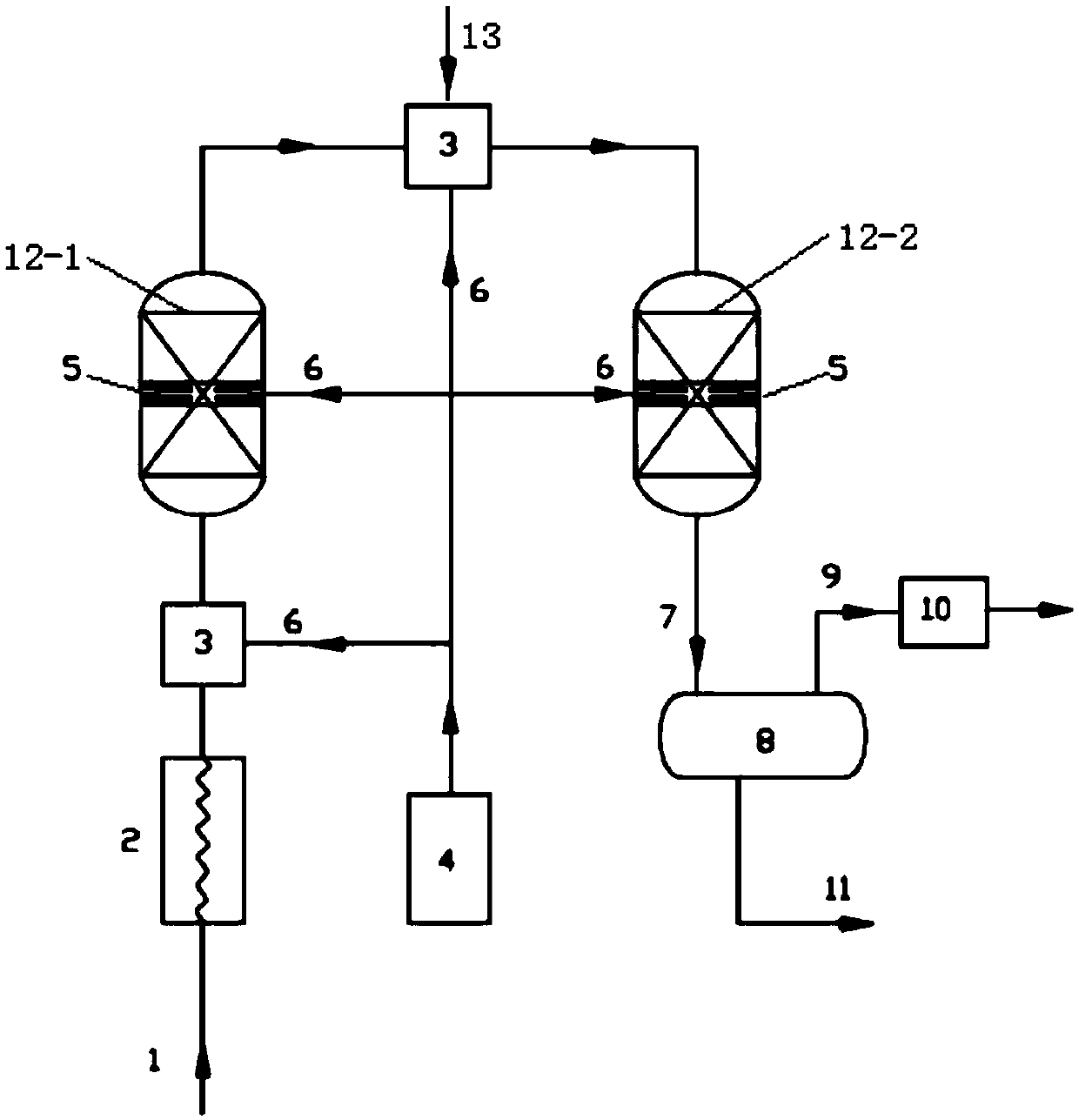

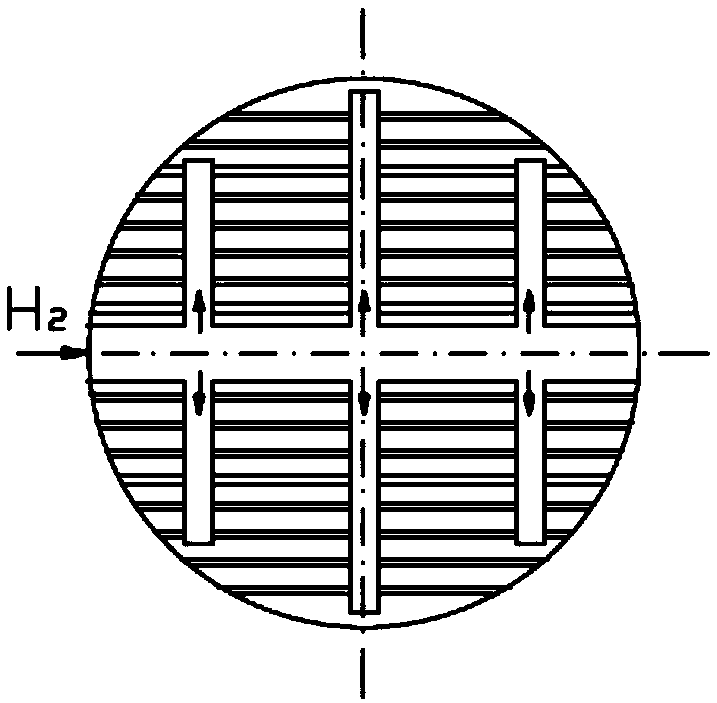

[0065] see figure 1 and figure 2 As shown, the waste plastic 1 (HDPE, high-density polyethylene) enters the oil-gas mixing equipment 3 through the heating furnace 2, and the hydrogen compressor 4 sends the hydrogen 6 into the oil-gas mixing equipment 3, and the waste plastic 1 and the hydrogen 6 are mixed and enter the first The liquid phase hydrogenation reactor 12-1 carries out the hydrocracking reaction, the first liquid phase hydrogenation reactor 12-1 is a thermal cracking reactor, and the thermal cracking reactor is a fixed bed reactor;

[0066] Wherein, the reaction conditions of the hydrocracking reaction are: a reaction temperature of 450° C., a hydrogen pressure of 1.5 MPa, and a reaction time of 1 h. The catalyst used in the hydrocracking reaction is a HZSM-5 molecular sieve catalyst;

[0067] The hydrocracking reaction product and Fischer-Tropsch wax enter the oil-gas mixing device 3 at a mass ratio of 1:1, and at the same time, the hydrogen compressor 4 sends h...

Embodiment 2

[0075] The difference from Example 1 is that the raw material is a 1:1 mixture of LDPE (low density polyethylene) and FT wax. Hydrocracking and hydroisomerization reaction conditions are consistent with embodiment 1, obtain product: C4 and below yield 2.8%, naphtha fraction yield 13.7%, diesel fraction yield is 30.5%, lubricating oil base oil total yield The rate is 55.8%. And, from the total base oil of lubricating oil, base oil products with a distillation range of 370-440 and a distillation range of 4CSt, and base oil products with a distillation range of >440°C and a distillation range of 6cSt are cut out.

[0076] According to the kinematic viscosity at 100°C, when the viscosity index reaches above 120, it belongs to Class III lubricating oil base oil, that is, high-grade lubricating oil base oil. (Classification refers to API lubricating oil standards and CNPC lubricating oil base oil industry standards)

[0077] The properties of the resulting product are shown in Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com