Fungus agent for reducing mildew of fermentation feed and mycotoxin harm and application

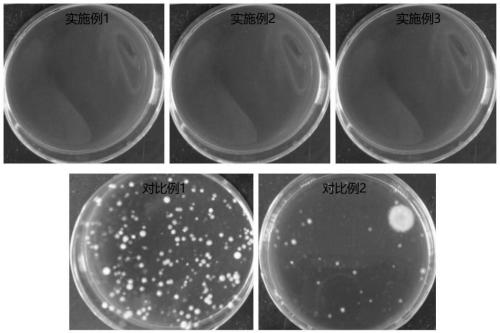

A technology for fermenting feed and mycotoxins, applied in the application, animal feed, animal feed and other directions, can solve the problem of easy breeding of mold, and achieve the effect of reducing the total amount of mold, reducing the content, and fast growth and reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

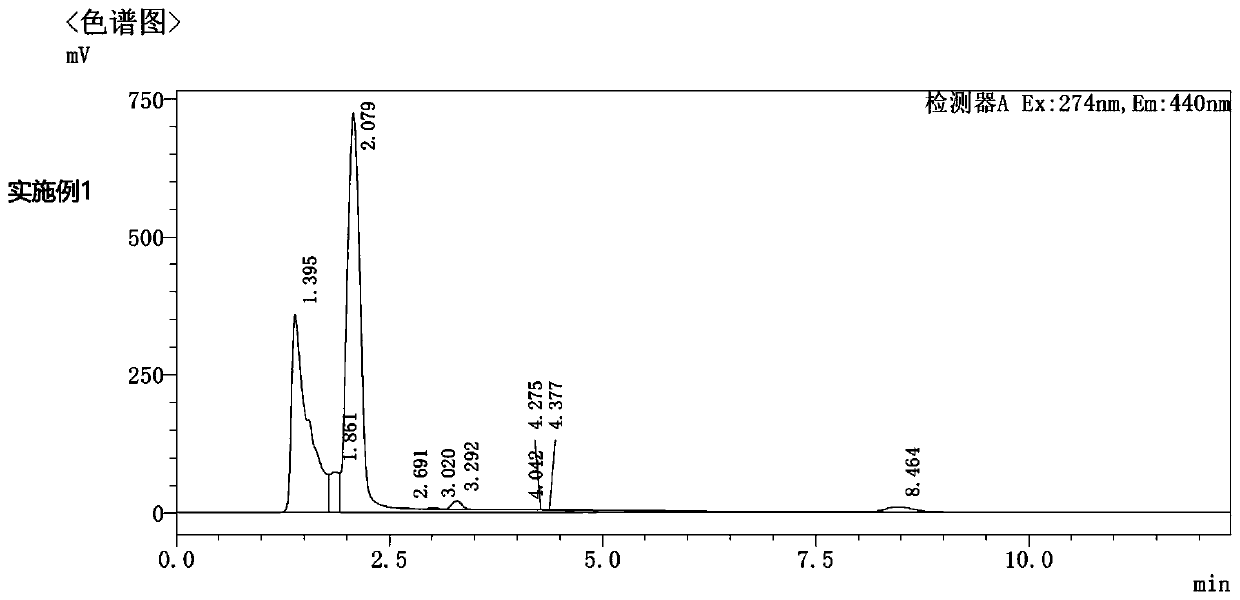

Embodiment 1

[0061] A method for preparing a microbial inoculant for reducing the mildew and mycotoxin hazards of fermented feed, comprising the following steps:

[0062] (1) Bacillus subtilis Bsbc01 was activated and cultured on LB solid medium plate at 37°C for 24 hours to obtain activated strains; then, the activated strains were inoculated in LB liquid medium for 18 hours with shaking at 37°C and 200rpm to obtain Seed liquid; then, the seed liquid is inoculated into the liquid medium with an inoculation amount of 6% by volume, and cultivated at 37°C for 24h to obtain a Bacillus subtilis bacterial liquid; then, add a protective agent in a proportion of 5%, and carry out at 112°C Spray-drying under wind temperature to obtain Bacillus subtilis dry powder;

[0063] Described expanded culture is that described liquid culture medium component is as follows, is weight percent:

[0064] Corn flour 2%, bean cake flour 3%, bran 2%, sodium citrate 0.5%, KH 2 PO 4 0.03%, K 2 HPO 4 0.01%, Ca...

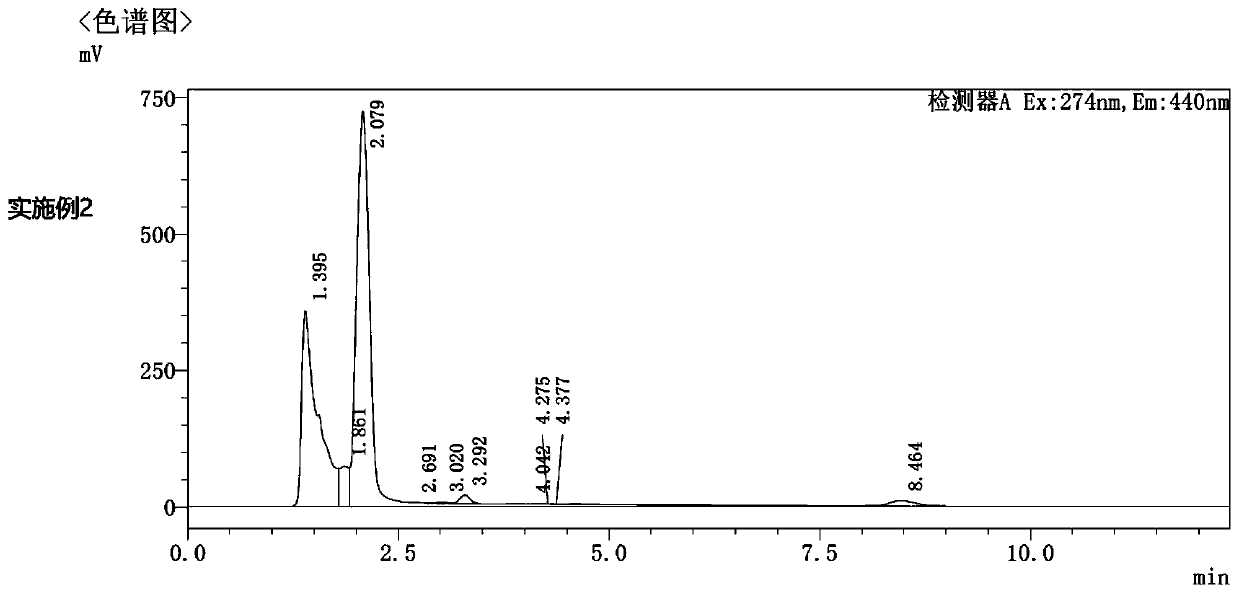

Embodiment 2

[0083] The microbial inoculant that reduces the mildew and mycotoxin hazards of fermented feed as described in Example 1 is different in that each gram includes the following active ingredients:

[0084] Bacillus subtilis Bsbc01 2×10 11 CFU, Candida utilis 2 x 10 10 cfu, lactic acid bacteria 5×10 10 cfu, compound enzyme preparation 500U, glucose 0.2g, peptone 0.4g;

[0085] The compound enzyme preparation is composed of neutral protease, acid protease, amylase, cellulase and NSP compound enzyme; the enzyme activity ratio of neutral protease, acid protease, amylase, cellulase and NSP compound enzyme is 2:3 :2:1:2.

[0086] The lactic acid bacteria are Lactobacillus plantarum, Lactobacillus casei and Streptococcus lactis mixed according to the ratio of live bacteria number = 1.5:2.5:1.

Embodiment 3

[0088] The microbial inoculant that reduces the mildew and mycotoxin hazards of fermented feed as described in Example 1 is different in that each gram includes the following active ingredients:

[0089] Bacillus subtilis Bsbc01 1×10 11 cfu, Candida utilis 1 x 10 10 cfu, lactic acid bacteria 5×10 10 cfu, compound enzyme preparation 100U, glucose 0.15g, peptone 0.35g;

[0090] The compound enzyme preparation is composed of neutral protease, acid protease, amylase, cellulase and NSP compound enzyme; the enzyme activity ratio of neutral protease, acid protease, amylase, cellulase and NSP compound enzyme is 2.5:2.5 :2.5:1:1.5.

[0091] The lactic acid bacteria are Lactobacillus plantarum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com