Anti-reflection film and polarizing plate having same

A technology of anti-reflection film and low refractive index layer, which is applied in the field of polarizing plates, can solve problems such as low peeling force, uneven film surface, white fog, etc., and achieve increased crosslinking density, small water contact angle, and good scratch resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

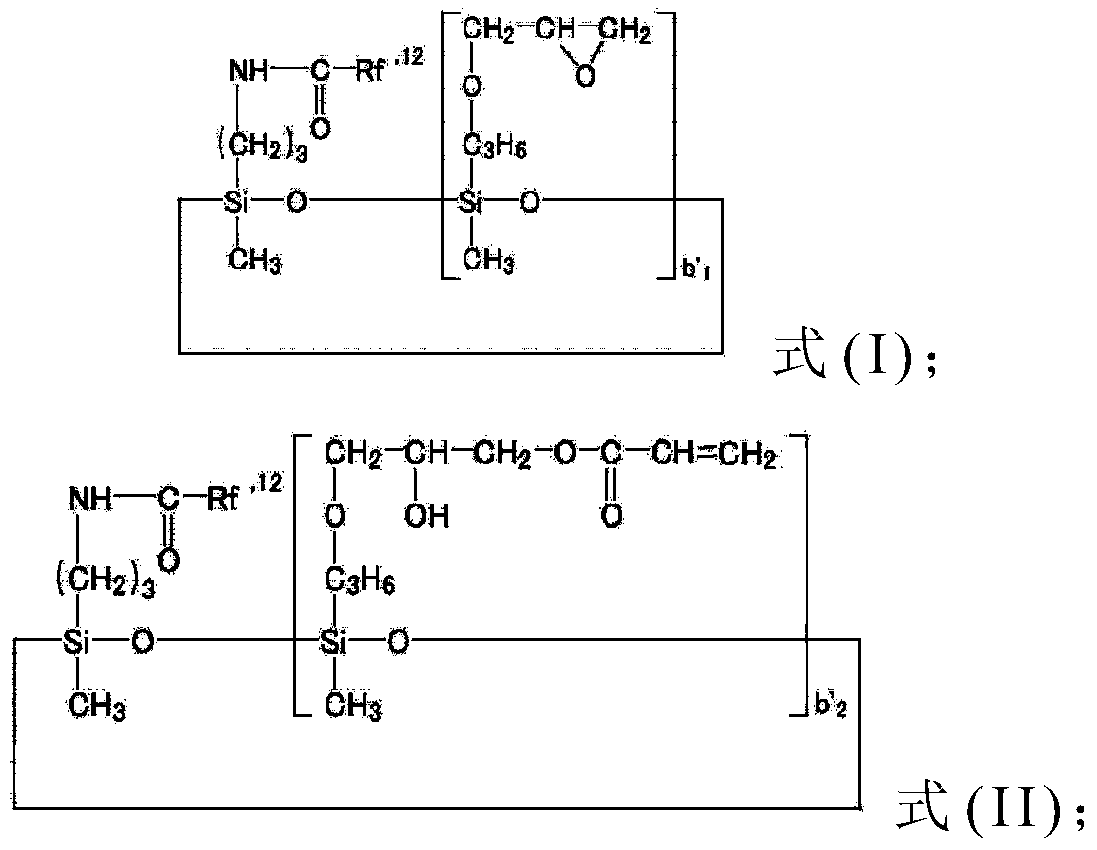

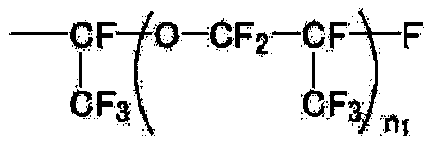

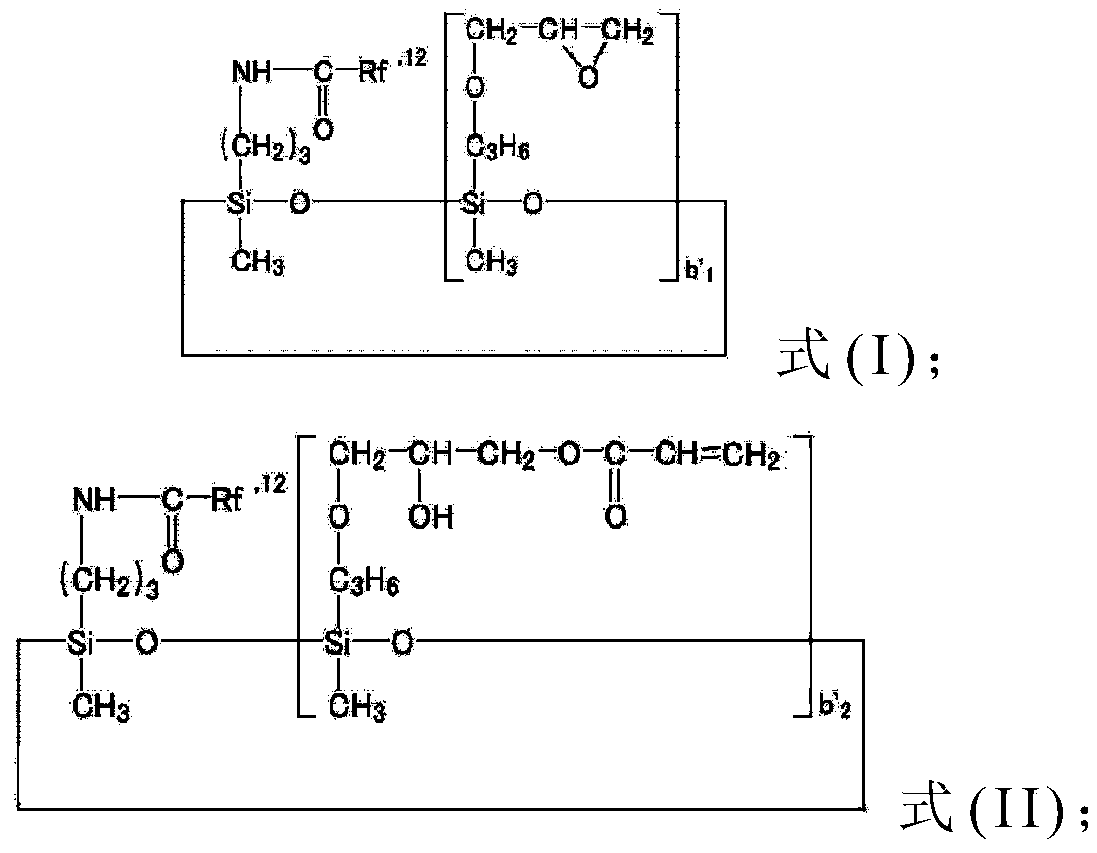

preparation example Construction

[0060] The preparation method of the anti-reflection film of the present invention comprises mixing polyurethane (meth)acrylate oligomer, initiator and appropriate solvent to form a hard coat solution, and the hard coat solution can be added (methyl) Acrylate monomer, organic microparticles, silica nanoparticles, or leveling agent; then apply the hard coat solution on the substrate, dry to remove the solvent, and then cure by radiation or electron beam to form on the substrate Form a hard coat layer; then the polysiloxane resin modified by fluorine and acrylate, hollow silicon dioxide nanoparticles, initiator, (meth)acryl modified with the aforementioned perfluoropolyether functional group The leveling agent of the organic silicon compound and the appropriate solvent are mixed uniformly to form a low refractive index layer solution. The low refractive index layer solution can be added with fluorinated polyurethane oligomers with 2 to 6 functionalities as required; the low refra...

preparation example 1

[0067] Preparation Example 1: Preparation of Antiglare Hard Coating Film

[0068] 405 parts by weight of urethane acrylate oligomer (functionality 9, molecular weight about 2,000, viscosity at 25°C is about 86,000 cps, purchased from Allnex, USA), 45 parts by weight of pentaerythritol triacrylate (PETA), 105 parts by weight Parts of dipentaerythritol hexaacrylate (DPHA), 45 parts by weight of hexanediol diacrylate (HDDA), 15 parts by weight of 2-phenoxyethyl acrylate (PHEA), 35 parts by weight of photoinitiator (Chemcure-481, purchased from Hengqiao Industry, Taiwan), 5 parts by weight of photoinitiator (TR-PPI-ONE, purchased from Qiangli New Materials, Hong Kong), 245 parts by weight of ethyl acetate (EAC) and 100 Parts by weight of n-butyl acetate (nBAC) were mixed and stirred for 1 hour to form a hard coating solution.

[0069] Then, 300 parts by weight of the aforementioned hard coat solution, 10.8 parts by weight of reactive silica nanoparticle dispersion sol (MEK-AC-413...

preparation example 2

[0070] Preparation Example 2: Preparation of Antiglare Hard Coating Film

[0071] 390 parts by weight of urethane acrylate oligomer (functionality 9, molecular weight about 2,000, viscosity at 25°C about 86,000 cps, purchased from Allnex, USA), 45 parts by weight of pentaerythritol triacrylate (PETA), 120 parts by weight Dipentaerythritol hexaacrylate (DPHA), 60 parts by weight of 2-phenoxyethyl acrylate (PHEA), 40 parts by weight of photoinitiator (Chemcure-481, purchased from Hengqiao Industry, Taiwan), 245 Parts by weight of ethyl acetate (EAC) and 100 parts by weight of n-butyl acetate (nBAC) were mixed and stirred for 1 hour to form a hard coating solution.

[0072] Then, with 300 parts by weight of the aforementioned hard coating solution, 5.44 parts by weight of reactive silica nanoparticle dispersion sol (MEK-5630X, solid content is 30%, solvent is methyl ethyl ketone, purchased from Guolian Silicon Industry, Taiwan) , 2.01 parts by weight of hydrophobically modified ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com