Method for predicting solid-liquid interface of Czochralski method monocrystalline silicon based on ANN

A prediction method and technology of single crystal silicon, which is applied in the self-melting liquid pulling method, single crystal growth, single crystal growth and other directions, can solve the problems of time-consuming, complicated calculation, and the growth process parameters do not have an explicit relationship, and achieve The effect of shortening calculation time, improving crystal quality, and saving R&D expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

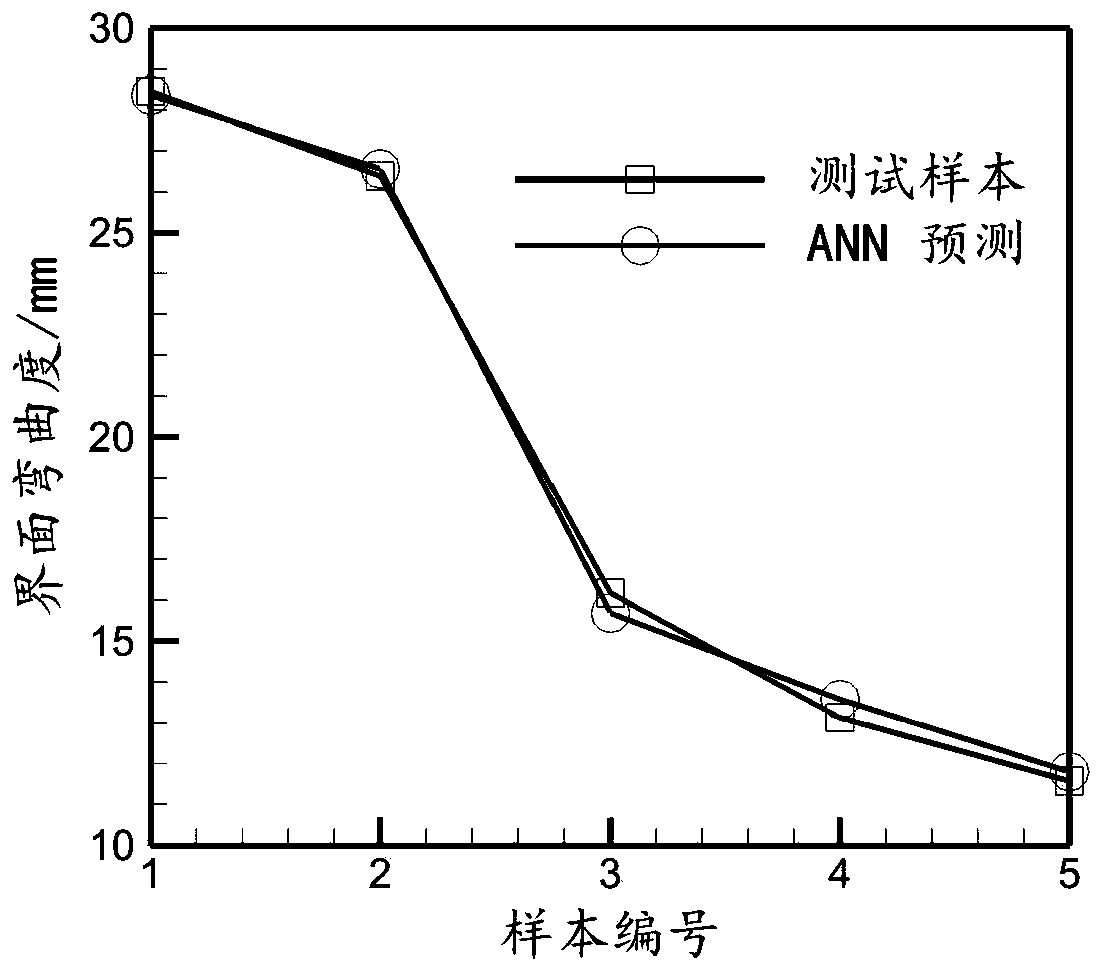

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

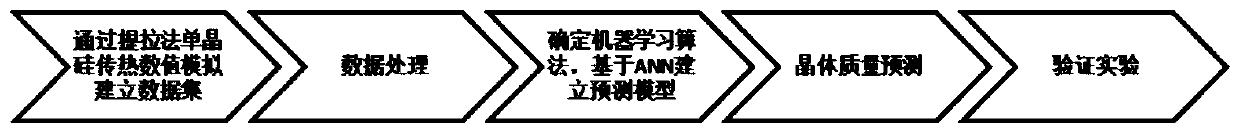

[0028] according to figure 1 The flow chart includes the following steps:

[0029] Step 1: Establish a data set by numerical simulation of heat transfer of single crystal silicon by pulling method

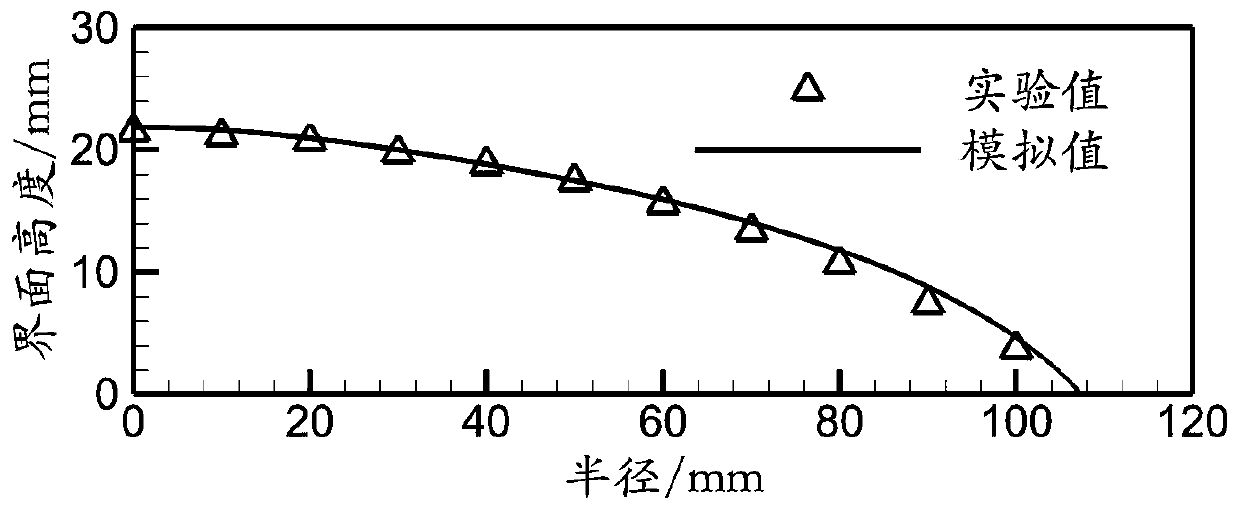

[0030] Gambit software is used to generate the global calculation grid of pulling method single crystal silicon, which mainly includes areas such as quartz crucible, graphite baffle, crystal, melt, guide tube and protective gas. The finite volume method is used to solve the mass, momentum and energy equations in the growth furnace, the interface tracking method is used to simulate the phase transition process, and a global two-dimensional axisymmetric heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com