Force-induced responsive supramolecular polymer

A supramolecular polymer and supramolecular technology, applied in the field of force-responsive supramolecular polymers, can solve problems such as single properties and performance, and difficulty in meeting the needs of multifunctional and intelligent materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

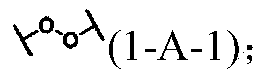

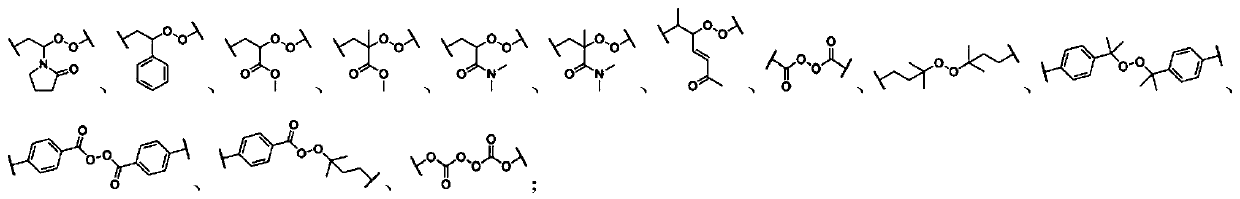

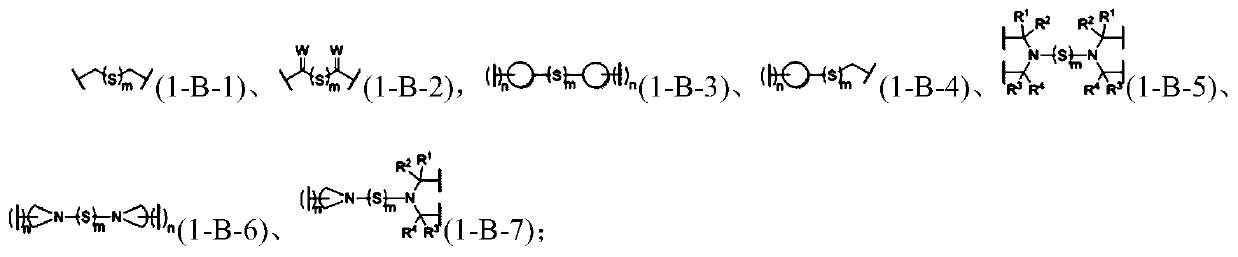

[0030] According to one embodiment of the present invention, there is provided a mechanoresponsive supramolecular polymer, which contains a mechanosensitive group and at least one selected from the group including but not limited to halogen bond interaction, cation-π interaction, anion-π interaction , Benzene-fluorobenzene interaction, π-π stacking interaction, ion interaction (positive and negative ion pair interaction), ion-dipole interaction, ionic hydrogen bond interaction, metalophilic interaction, free radical cation dimerization, Lewis acid-base pair interaction . Supramolecular interactions of host-guest interactions; wherein at least one supramolecular interaction causes phase separation and / or crystallization.

[0031] According to another embodiment of the present invention, there is provided a method for realizing mechanoresponse, which is characterized in that a mechanoresponse supramolecular polymer is provided, which contains a mechanosensitive group and at least...

Embodiment 1

[1713]Example 1 Dissolve limonene oxide and catalyst in toluene under anhydrous and air-free conditions of 90°C, keep the molar ratio of limonene oxide and catalyst at 50:1, feed 10bar carbon dioxide into the reaction vessel, and after the reaction is complete, the crude The product was precipitated with methanol to obtain polylimonene carbonate a terminated by a hydroxyl group. Polymer a and excess n-butyl 3-mercaptopropionate are dissolved in tetrahydrofuran and fully blended, reacted in the presence of a photoinitiator BDK and irradiated by an ultraviolet lamp to obtain polymer b. Equivalent molar equivalents of 2-maleimidoacetic acid and polymer b are reacted under the catalysis of DCC and DMAP to obtain polymer c with a maleimide group at one end. The equimolar equivalents of compound d and polymer a were reacted under the catalysis of DCC and DMAP to obtain polylimonene carbonate e with a lysensitizing group precursor at one end. Reacting equimolar equivalents of heptaf...

Embodiment 2

[1716] Example 2 Ethyl adamantane-1-carboxylate and hydroxyethyl methacrylate in equivalent molar equivalents were transesterified to obtain a methacrylate monomer a containing adamantane. Using 1 molar equivalent of benzoyl peroxide (BPO) as the initiator and 1 molar equivalent of thioglycolic acid as the chain transfer agent at 90 ° C to initiate the polymerization of 50 molar equivalents of monomer a and 50 molar equivalents of tert-butyl methacrylate to obtain single-ended Carboxy-terminated part of the pendant group is adamantane polymer b. Using 1 molar equivalent of benzoyl peroxide (BPO) as the initiator and 1 molar equivalent of thioglycolic acid as the chain transfer agent at 90°C to initiate the polymerization of 100 molar equivalents of tert-butyl methacrylate, a single-terminal carboxyl-terminated polymer c was obtained. Reaction of equimolar equivalents of polymer b and lysensitizing group d under the catalysis of DCC and DMAP, linking the polymer with the hydrox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com