Medicated leaven fermentation pretreatment process and medicated leaven

A six-divine song and pre-treatment technology, applied in the direction of plant raw materials, digestive system, plant/algae/fungus/moss components, etc., can solve the problems of large damage to active substances, ineffective effect, and slightly improved degree of improvement, and achieve The degree of fermentation is thorough, the effect of strengthening the spleen and stomach, and the effect of good enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

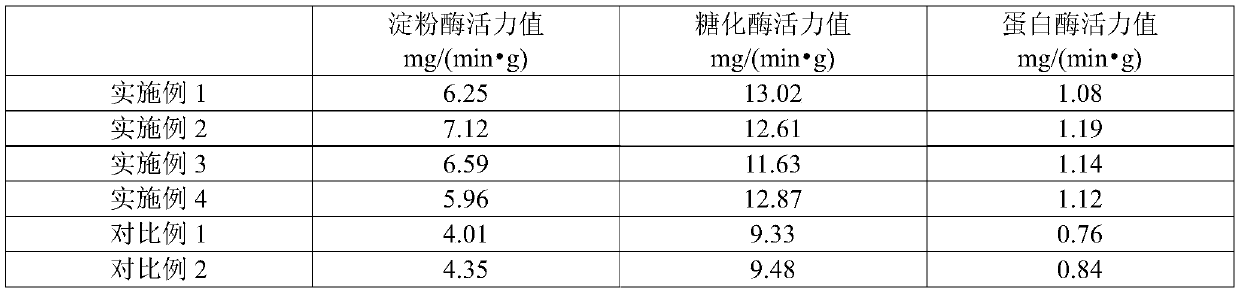

Examples

Embodiment 1

[0034] A pre-treatment process for fermentation of Liushenqu includes the following steps:

[0035] a) Preparation: Prepare the raw materials in the following parts by weight: 100 parts of wheat flour, 90 parts of bran, 80 parts of red bean flour, 80 parts of bitter almond powder, 95 parts of fresh artemisia annua, 85 parts of fresh spicy polygonum, 95 parts of fresh Xanthium ;

[0036] b) Preparation of three fresh juices: chopped fresh Artemisia annua, Polygonum and fresh Xanthium, add 50wt% water of the total weight of Artemisia annua, Polygonum and fresh Xanthium, and add fresh A. annua 10wt% of pectinase, and adjusted the pH to 3.0, stirred at 27°C at 4 rpm for 4 hours, then adjusted the pH to 7.0, and then pressed to obtain three fresh juice

[0037] c) Enzymatic hydrolysis: adding 3wt% cellulase of the Sanxian juice to the prepared Sanxian juice, and agitating for 2 hours at 27°C and 4rpm to prepare the enzymatic hydrolyzing Sanxian juice;

[0038] d) Preparation: mix wheat fl...

Embodiment 2

[0043] A pre-treatment process for fermentation of Liu Shenqu, including the following steps:

[0044] a) Preparation: Prepare the raw materials according to the following parts by weight, 100 parts of wheat flour, 95 parts of bran, 85 parts of red bean flour, 85 parts of bitter almond powder, 100 parts of fresh artemisia annua, 90 parts of spicy polygonum, and 100 parts of fresh cocklebur ;

[0045] b) Preparation of three fresh juices: chopped fresh Artemisia annua, Polygonum and fresh Xanthium, add 55wt% water of the total weight of Artemisia annua, Polygonum and fresh Xanthium, and add fresh A. annua 12wt% pectinase, and adjust the pH to 3.2, stir for 4.5 hours at 29°C at 5 rpm, then adjust the pH to 7.2, and then squeeze to obtain three fresh juice;

[0046] c) Enzymatic hydrolysis: adding 4wt% cellulase of the Sanxian juice to the prepared Sanxian juice, and stirring for 2.5 hours at 29°C and 5rpm to prepare the enzymatically hydrolyzed Sanxian juice;

[0047] d) Preparation: m...

Embodiment 3

[0052] A pre-treatment process for fermentation of Liu Shenqu, including the following steps:

[0053] a) Preparation: Prepare the raw materials in the following parts by weight, 100 parts of wheat flour, 105 parts of bran, 95 parts of red bean flour, 95 parts of bitter almond flour, 100 parts of fresh artemisia annua, 110 parts of fresh and spicy polygonum, 100 parts of fresh Xanthium ;

[0054] b) Preparation of three fresh juices: chopped fresh Artemisia annua, Polygonum and fresh Xanthium, add 55wt% water of the total weight of Artemisia annua, Polygonum and fresh Xanthium, and add fresh A. annua 13wt% of pectinase, and adjust the pH to 3.3, stir for 5.5 hours at 30°C at 5 rpm, then adjust the pH to 7.3, and then press to obtain three fresh juices;

[0055] c) Enzymatic hydrolysis: add 6wt% cellulase of the Sanxian juice to the prepared Sanxian juice, and stir for 2.5 hours at 30°C and 5rpm to prepare the enzymatically hydrolyzed Sanxian juice;

[0056] d) Preparation: mix wheat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com