Antibacterial inorganic high-performance mineral artificial slabstone and preparation method thereof

An artificial slate, high-performance technology, applied in the field of artificial stone, can solve the problems of low density of modified diatomite, affecting the fluidity of mortar, easy to deform and crack, and achieve uniform dispersion, good self-cleaning performance and durability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

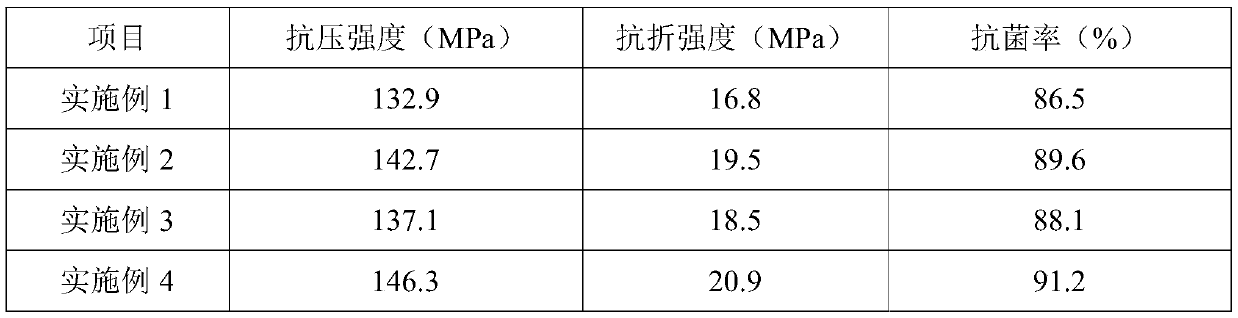

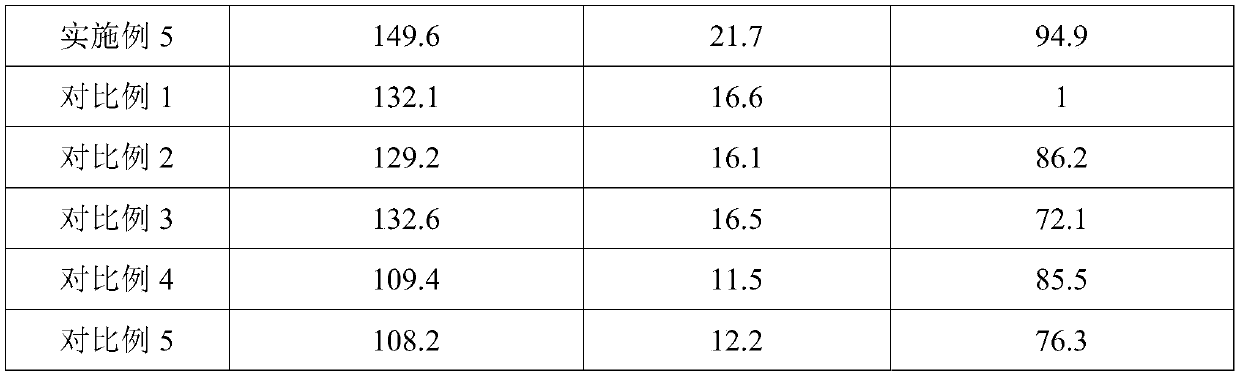

Examples

Embodiment 1

[0052] An antibacterial inorganic high-performance mineral artificial stone slab, comprising the following raw materials in parts by weight:

[0053] 60 parts of cement whose strength is not less than 32.5MPa;

[0054] 50 parts of admixtures with an average particle size of 5-30 μm;

[0055] 80 parts of fine aggregate with an average particle size of 0.15-4.75mm;

[0056] 0.2 parts of loaded antibacterial agent with an average particle diameter of 20-100 nm;

[0057] 0.5 parts of water repellent;

[0058] 3 parts of pigment;

[0059] 3 parts of high-performance admixture;

[0060] The ratio of water to glue is 0.16.

[0061]The load-type antibacterial agent is composed of a carrier and an antibacterial agent in a mass ratio of 1:0.5 to 1.2, and the carrier is porous nano calcium carbonate with an average particle diameter of 20 to 100nm; the antibacterial agent is nano silver oxide, silver chloride, silver nitrate, One or more combinations of copper phthalocyanine; the f...

Embodiment 2

[0072] Except that the formula of antibacterial inorganic high-performance mineral artificial stone board is different, other conditions are the same as embodiment 1.

[0073] The antibacterial inorganic high-performance mineral artificial stone board includes the following raw materials in parts by weight:

[0074] 100 parts of cement whose strength is not less than 32.5MPa;

[0075] 80 parts of admixtures with an average particle size of 5-30 μm;

[0076] 130 parts of fine aggregate with an average particle size of 0.15-4.75mm;

[0077] 0.8 parts of loaded antibacterial agent with an average particle diameter of 20-100nm;

[0078] 2 parts of water repellent;

[0079] 10 parts of pigment;

[0080] 5 parts of high-performance admixture;

[0081] The ratio of water to glue is 0.2.

Embodiment 3

[0083] Except that the formula of antibacterial inorganic high-performance mineral artificial stone board is different, other conditions are the same as embodiment 1.

[0084] The antibacterial inorganic high-performance mineral artificial stone board includes the following raw materials in parts by weight:

[0085] 70 parts of cement whose strength is not less than 32.5MPa;

[0086] 60 parts of admixtures with an average particle size of 5-30 μm;

[0087] 95 parts of fine aggregate with an average particle size of 0.15-4.75 mm;

[0088] 0.35 parts of loaded antibacterial agent with an average particle diameter of 20-100 nm;

[0089] 0.9 parts of water repellent;

[0090] 5 parts of pigment;

[0091] 3.5 parts of high-performance admixture;

[0092] The ratio of water to glue is 0.17.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com