Synthesis method of p-hydroxyphenylethanol

A technology for p-hydroxyphenethyl alcohol and a synthesis method, which is applied in the field of synthesis of p-hydroxyphenethyl alcohol, can solve the problems of high raw material cost, strict requirements on production equipment and raw materials, complicated processes, etc., and achieves simple and mild reaction conditions, low cost, and high efficiency. Handling simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

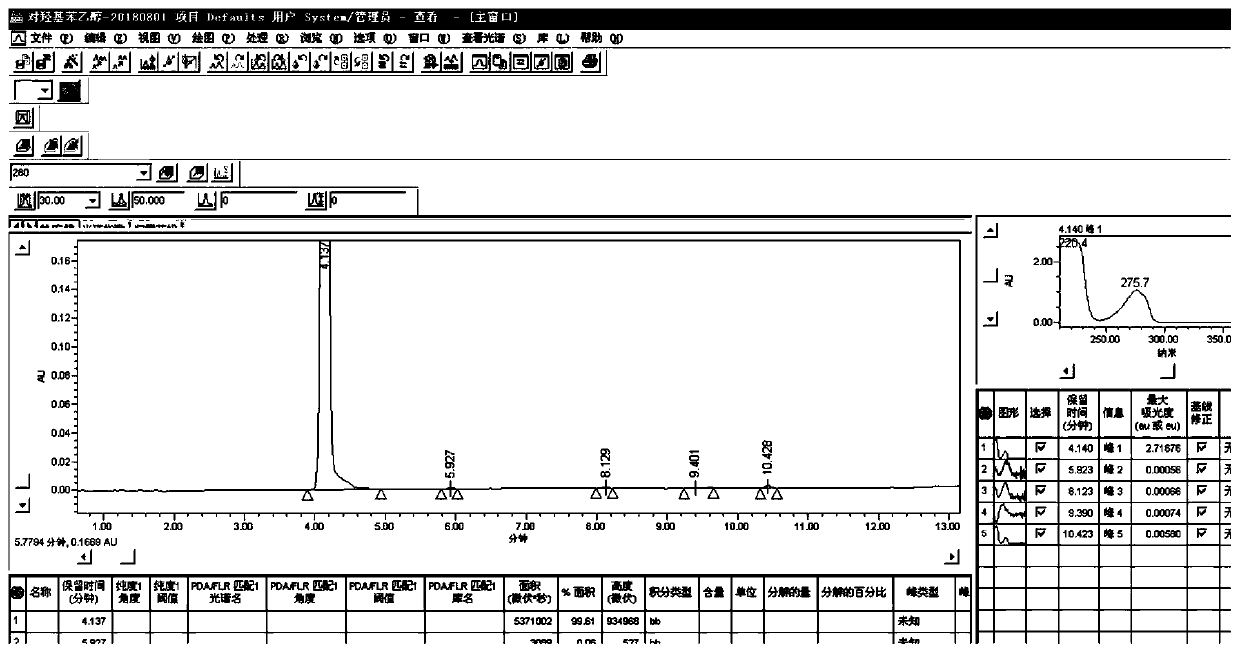

Image

Examples

preparation example Construction

[0032] A method for synthesizing p-hydroxyphenethyl alcohol, including the following steps:

[0033] 1) Add methanol, sodium methoxide and catalyst to the reactor and stir; the catalyst is selected from potassium iodide and cuprous iodide; the amount of the catalyst is 0.05-0.1 times the mass of 4-chlorophenylethanol.

[0034] 2) Add 4-chlorophenethyl alcohol to the above reactor in batches, and heat to reflux temperature to react; the amount of methanol is 3-6 times the mass of 4-chlorophenethyl alcohol. The molar ratio of sodium methoxide and 4-chlorophenethyl alcohol is 5-10:1.

[0035] 3) The solution obtained in step 2) is cooled to room temperature, filtered, and the filtrate is evaporated to dryness to obtain crude 4-methoxyphenethyl alcohol;

[0036] 4) Put the crude 4-methoxyphenethyl alcohol obtained in step 3) into another reactor, add a solvent, and stir; the solvent is formic acid or acetic acid, and the amount of solvent used is 4% by weight of the crude 4-methoxypheneth...

Embodiment 1

[0041] 1) Add 15kg of methanol, 5.4kg of sodium methoxide and 0.23kg of CuI to the reactor at room temperature to start stirring.

[0042] 2) Add 3.13 kg of 4-chlorophenethyl alcohol to the above mixture in batches, and heat to reflux at about 80 degrees.

[0043] 3) The material is cooled to room temperature, filtered, and the filtrate is spin-dried to obtain crude 4-methoxyphenethyl alcohol: 3kg.

[0044] 4) Put the obtained materials into the reaction kettle, add 15 kg of glacial acetic acid, and stir at room temperature.

[0045] 5) Add 10.3kg of 47% hydrobromic acid dropwise to it, heat up to 116°C, keep refluxing.

[0046] 6) Sampling and testing, the reaction of 4-methoxyphenethyl alcohol is completed, and the temperature is reduced to about 60°C. Slowly add 20% sodium carbonate solution dropwise to the material while observing the reaction pH value. When the pH is between 6-7, stop the dripping.

[0047] 7) Continue the heat preservation reaction for 2h, lower the temperature t...

Embodiment 2

[0050] 1) Add 15kg of methanol, 8.6kg of sodium methoxide and 0.27kg of KI to the reaction kettle at room temperature to start stirring.

[0051] 2) Add 3.13 kg of 4-chlorophenethyl alcohol to the above mixed solution in batches, and heat to reflux at around 84 degrees.

[0052] 3) The material is cooled to room temperature, filtered, and the filtrate is spin-dried to obtain crude 4-methoxyphenethyl alcohol: 2.96kg.

[0053] 4) Put the obtained materials into the reaction kettle, add 17.7 kg of glacial acetic acid, and stir at room temperature.

[0054] 5) Add 12.1 kg of 40% hydrobromic acid dropwise to it, heat up to 116°C, keep refluxing.

[0055] 6) Sampling and testing, the reaction of 4-methoxyphenethyl alcohol is completed, and the temperature is lowered to about 60°C. Slowly add 10% sodium hydroxide solution dropwise to the material while observing the reaction pH value. When the pH is between 6-7, stop the dripping.

[0056] 7) Continue the heat preservation reaction for 2h, lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com