Adhesive for corn straw scrimber and preparation method of adhesive

A technology of corn stalks and recombined materials, which is applied in adhesives, applications, household components, etc., can solve the problems of high organic volatile matter release and formaldehyde release, and achieve improved comprehensive performance, improved bonding performance, and excellent water and weather resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

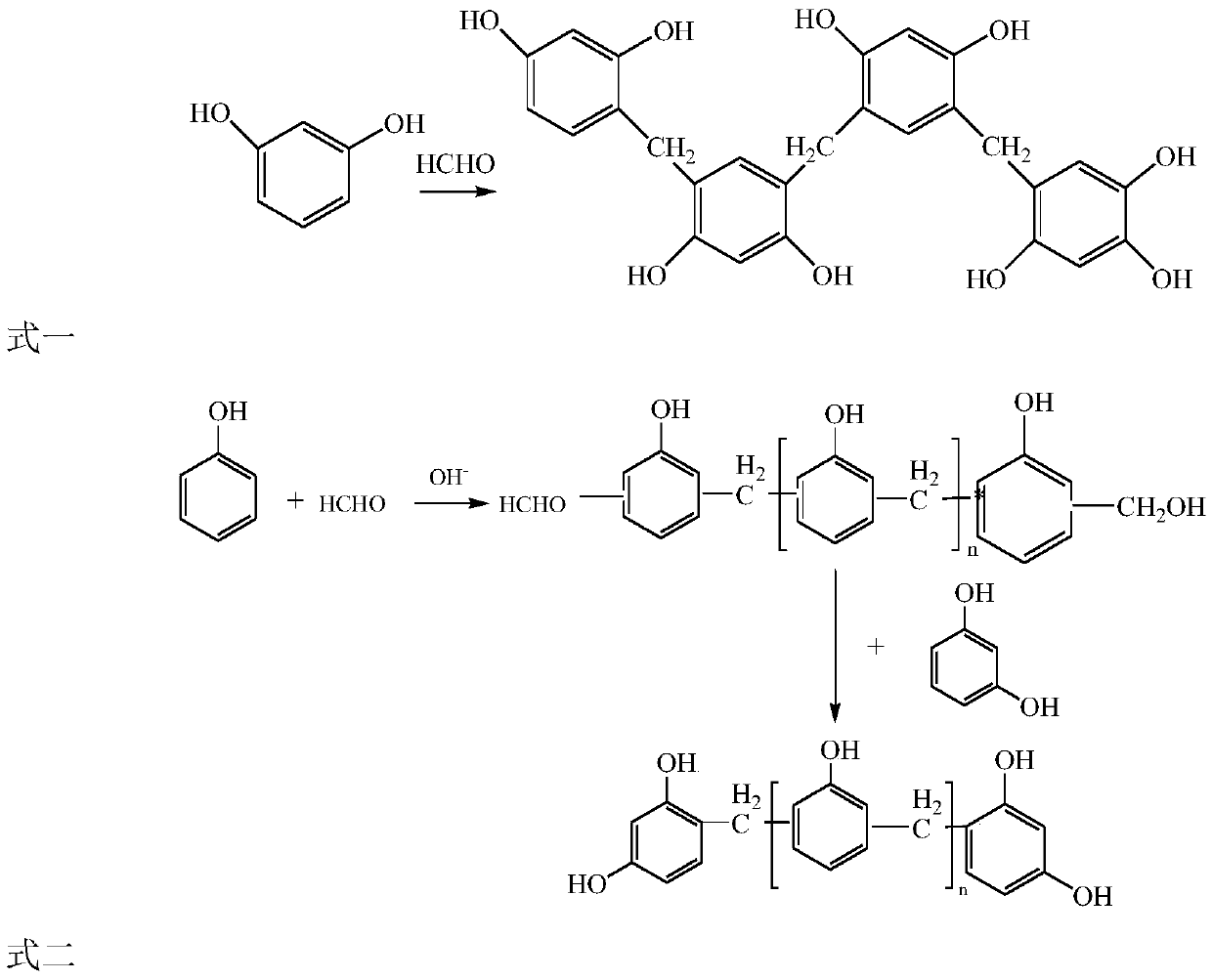

Method used

Image

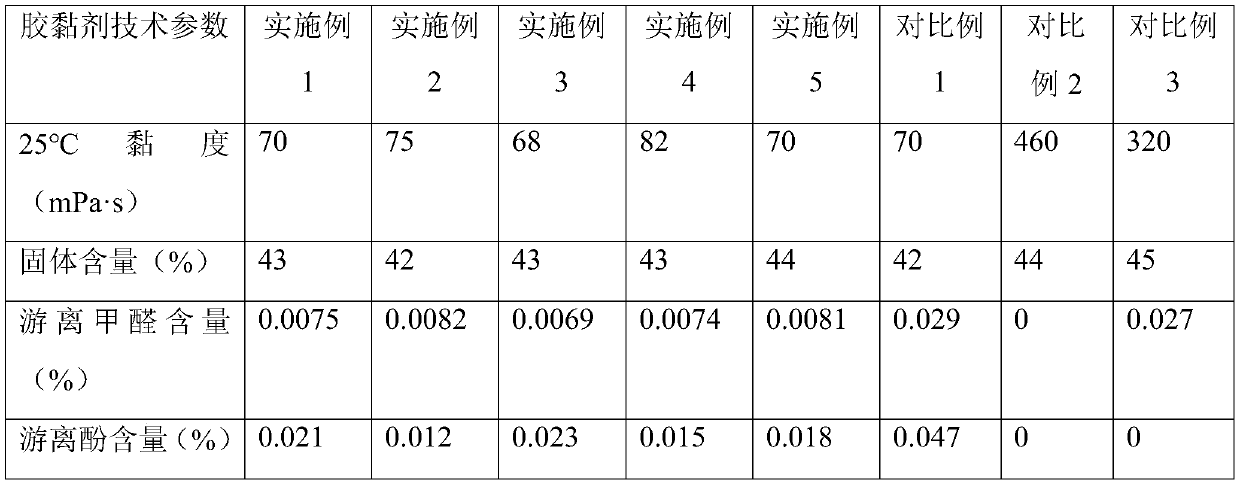

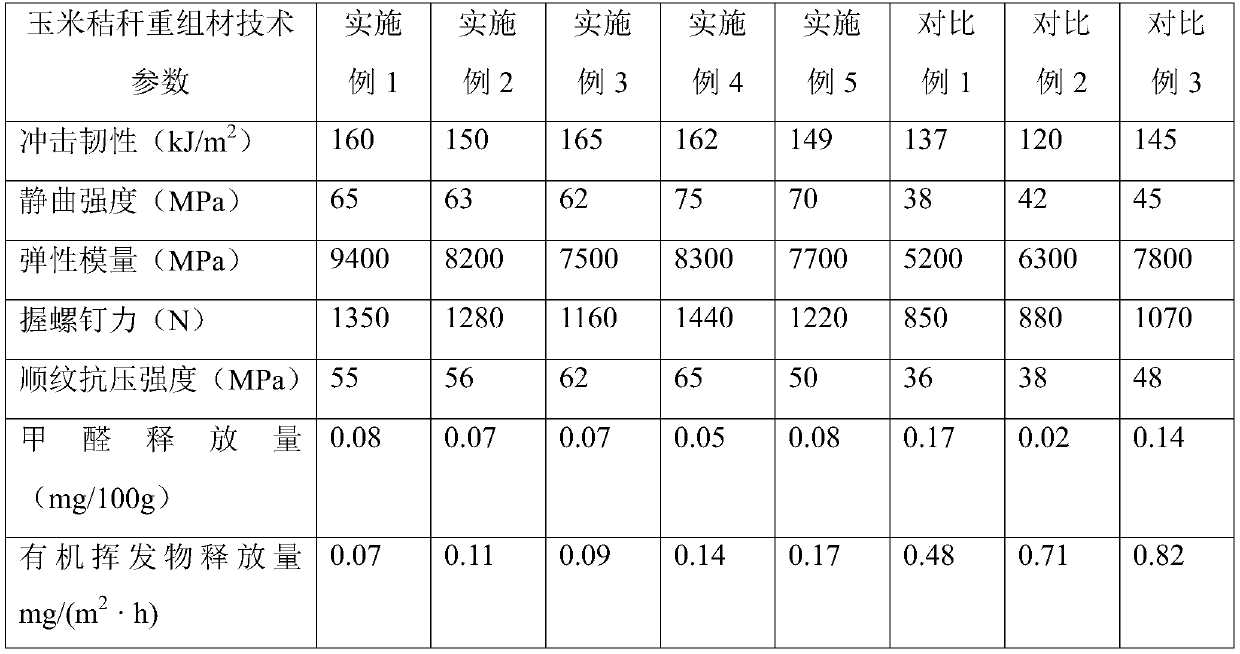

Examples

Embodiment 1

[0024] The preparation method of the adhesive for corn straw recombined wood is as follows:

[0025] The adhesive described in A first mixes 376 parts of formaldehyde aqueous solution with a mass concentration of 37.4%, 198 parts of phenol, 180 parts of water and the first batch of 4 parts of 45wt% sodium hydroxide aqueous solution, and heats up to 90-95° C. for 2 hours after mixing;

[0026] B lowered the temperature to 75°C and added 67 parts of the second batch of 45wt% sodium hydroxide aqueous solution, and raised the temperature to 85°C for 1.5 hours;

[0027] C After the reaction is completed, the temperature is lowered to 67°C, and the third batch of 66 parts of 45wt% sodium hydroxide aqueous solution and 18 parts of resorcinol are added, and after 10 minutes of reaction, the temperature is lowered to 40°C and the material is discharged to obtain a new type of adhesive for corn stalks. .

[0028] The surface of the decomposed corn stalks was sprayed with glue, the amou...

Embodiment 2

[0030] The preparation method of the adhesive for corn straw recombined wood is as follows:

[0031] The adhesive described in A first mixes 395 parts of formaldehyde aqueous solution with a mass concentration of 36.5%, 200 parts of phenol, 190 parts of water, and the first batch of 7 parts of 45% potassium hydroxide aqueous solution, and heats up to 90-95° C. for 2 hours after mixing;

[0032] B lowered the temperature to 75°C and added 69 parts of the second batch of 45% potassium hydroxide aqueous solution, and raised the temperature to 85°C for 1.5 hours;

[0033] C After the reaction, cool down to 67°C and add the third batch of 68 parts of 45% potassium hydroxide aqueous solution and 19 parts of resorcinol. After reacting for 10 minutes, cool down to 40°C and discharge to obtain a new adhesive for corn straw recombination.

[0034] The surface of the decomposed corn stalks was sprayed with glue, the amount of glue applied was 13% of the mass of the corn stalks. After for...

Embodiment 3

[0036] The preparation method of the adhesive for corn straw recombined wood is as follows:

[0037] For the adhesive described in A, 400 parts of formaldehyde aqueous solution with a mass concentration of 37.2%, 210 parts of phenol, 200 parts of water and 8 parts of the first batch of 45% potassium hydroxide aqueous solution were first heated to 90-95° C. for 2 hours;

[0038] B lowered the temperature to 75°C and added 70 parts of the second batch of 45% potassium hydroxide aqueous solution, and raised the temperature to 85°C for 1.5 hours;

[0039] C After the reaction, cool down to 67°C and add the third batch of 68 parts of 45% potassium hydroxide aqueous solution and 21 parts of resorcinol. After reacting for 10 minutes, cool down to 40°C and discharge to obtain a new type of adhesive for corn stalks.

[0040] The surface of the decomposed corn stalks was sprayed with glue, the amount of glue applied was 13% of the mass of the corn stalks. After forming the billet, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com