Copper-nickel sludge resource recycling process

A technology of copper sludge and sludge, which is applied in the field of copper-nickel sludge resource recycling technology, can solve the problems of long nickel recovery process, low overall recovery rate, increased production cost, etc., achieve priority efficient recovery and improve recovery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

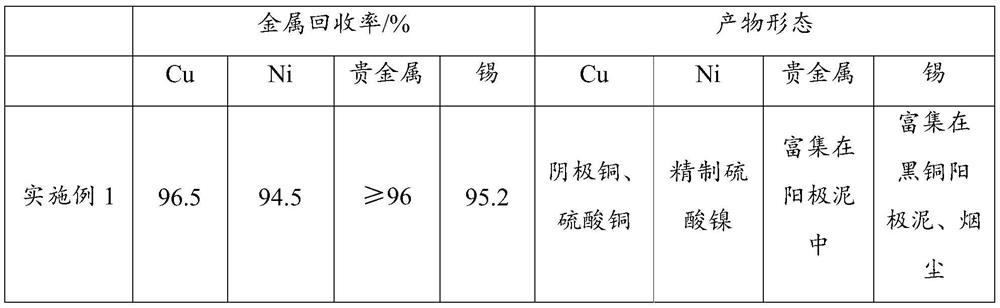

Embodiment 1

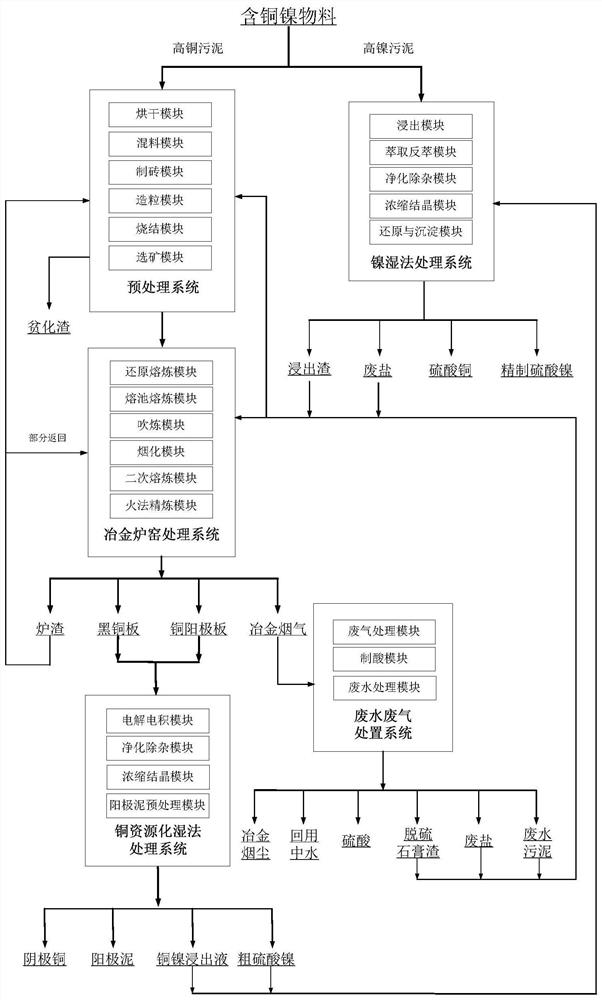

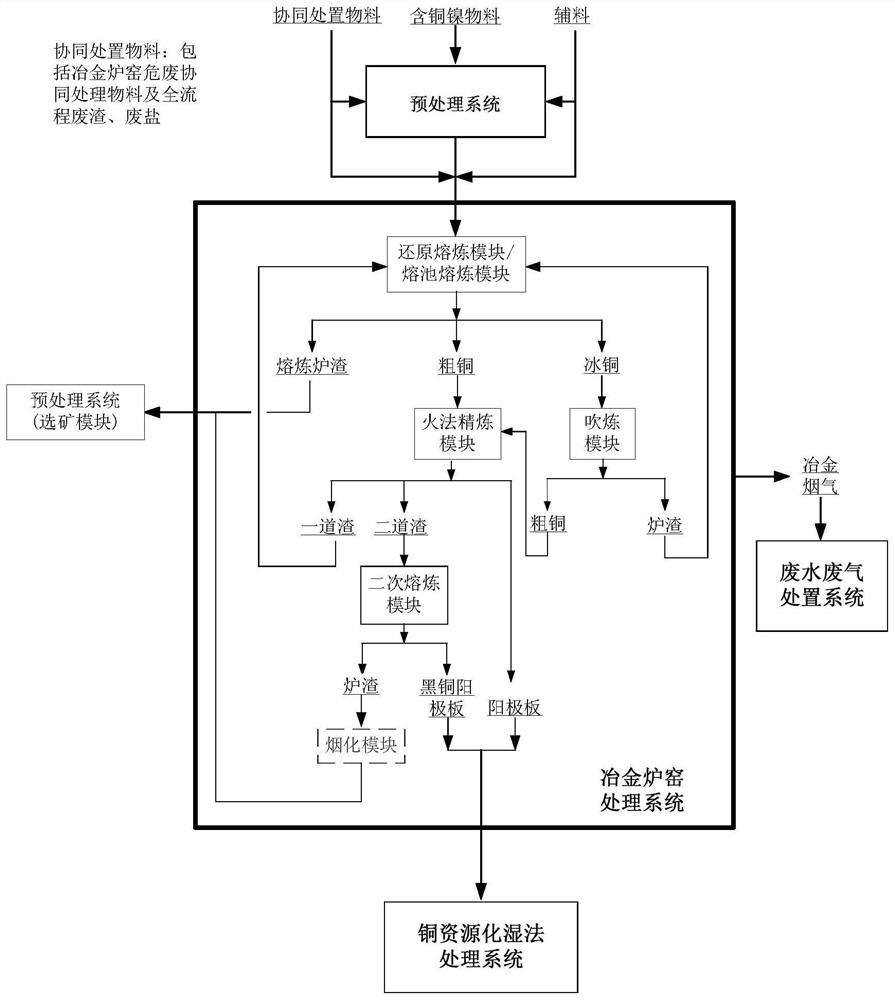

[0090] Please refer to figure 1 with figure 2 , the present embodiment provides a copper-nickel sludge resource recycling process, including:

[0091] The dry basis of copper-containing sludge contains 15% copper, 2% nickel, 0.5% tin, and a small amount of precious metals. Treated by fire method. After the copper-containing sludge is dried to about 50% water content through the pretreatment process, it is mixed with waste salt, desulfurized gypsum, scrap iron sludge and other materials, and then pretreated (after brick making or sintering) and other raw and auxiliary materials (reduction Carbon concentrate, quartz stone, limestone, etc.) enter the smelting treatment process together for reduction smelting or molten pool smelting. This process mainly occurs the solidification of the above-mentioned sulfur to form a matte phase, iron, silicon, calcium, sodium, etc. solidify into the slag phase, and produce blister copper, matte, slag and soot, and the matte is used for blowi...

Embodiment 2

[0095] This embodiment provides a recycling process for copper-nickel sludge resources, including:

[0096] Copper-containing sludge contains 5% copper, 8% nickel and 0.5% tin on a dry basis, and also contains trace amounts of precious metals. Treated by wet process. Sulfuric acid is used for countercurrent leaching. After neutralization and purification to remove impurities such as iron and aluminum, the leaching solution is extracted and back-extracted to obtain copper sulfate solution or copper sulfate crystals. After a small amount of copper, iron, etc., nickel extraction and stripping are carried out to obtain a high-purity nickel sulfate solution, which is used for further evaporation and crystallization to prepare refined nickel sulfate products. After neutralization and precipitation, the final raffinate is evaporated and concentrated. Waste salt is obtained; various leaching slags, precipitation slags, and impurity-removing slags obtained in the whole process are all...

Embodiment 3

[0098] This embodiment provides a recycling process for copper-nickel sludge resources, which differs from Embodiment 1 only in that:

[0099] After the copper anode plate and refining slag are obtained by refining, the refining slag is not distinguished, and the refining slag is directly subjected to reduction smelting or molten pool smelting. In the wet process of copper resource recovery, only the copper anode plate is electrolytically refined.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com