Ecological slope protection precast blocks and preparation method and application thereof

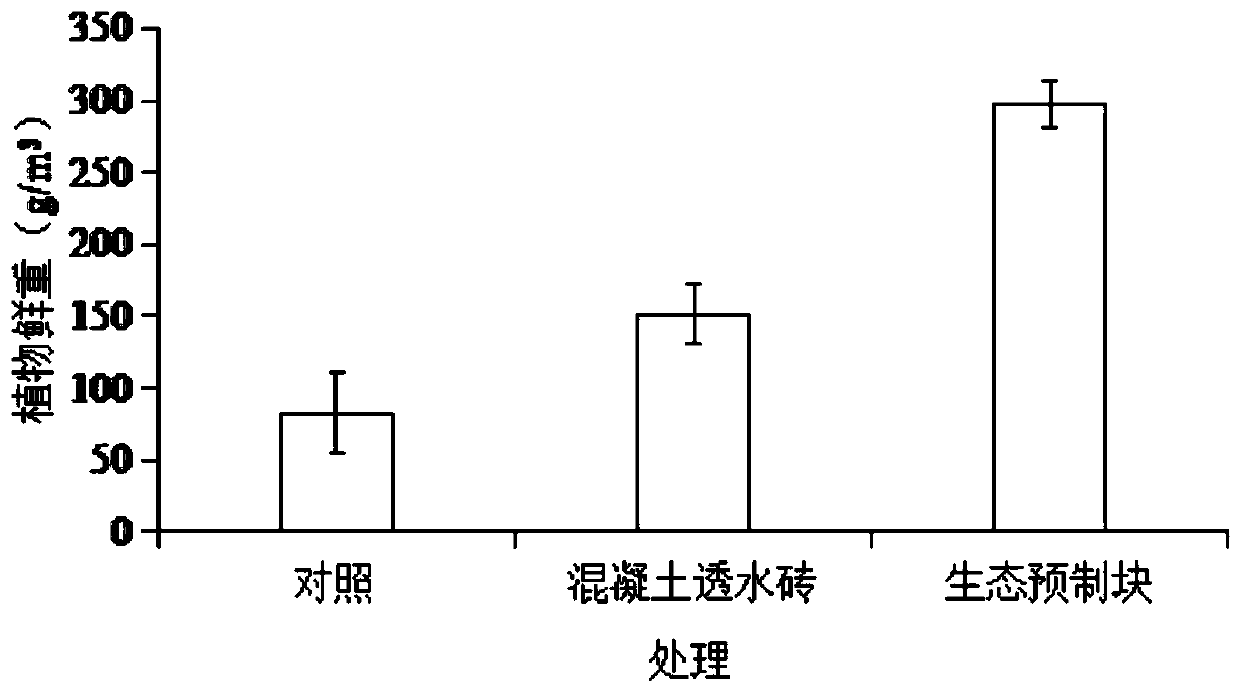

A technology of ecological slope protection and prefabricated blocks, applied in the direction of botanical equipment and methods, applications, chemical instruments and methods, etc., can solve the problems of large resource consumption, large amount of cement, sand and gravel, etc., to promote absorption and slope stability Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] ① Preparation of curing agent for ecological slope protection prefabricated blocks

[0039] Mix 4 parts by mass of quicklime, 5 parts by mass of fly ash, 0.5 parts by mass of magnesium oxide and 2 parts by mass of calcium sulfate powder to obtain the curing agent required for the product.

[0040] ② Preparation of microbial envelopes

[0041] 15 parts by mass Trichoderma reesei Trichoderma reesei T131 bacterial agent and 8 parts by mass of Bacillus subtilis Bacillus subtilis Mix D9 microbial agent with 1 mass part of urea-formaldehyde resin liquid, add 0.2 mass part of coagulant ammonium chloride, stir evenly, and spray granulate to obtain microbial coating body.

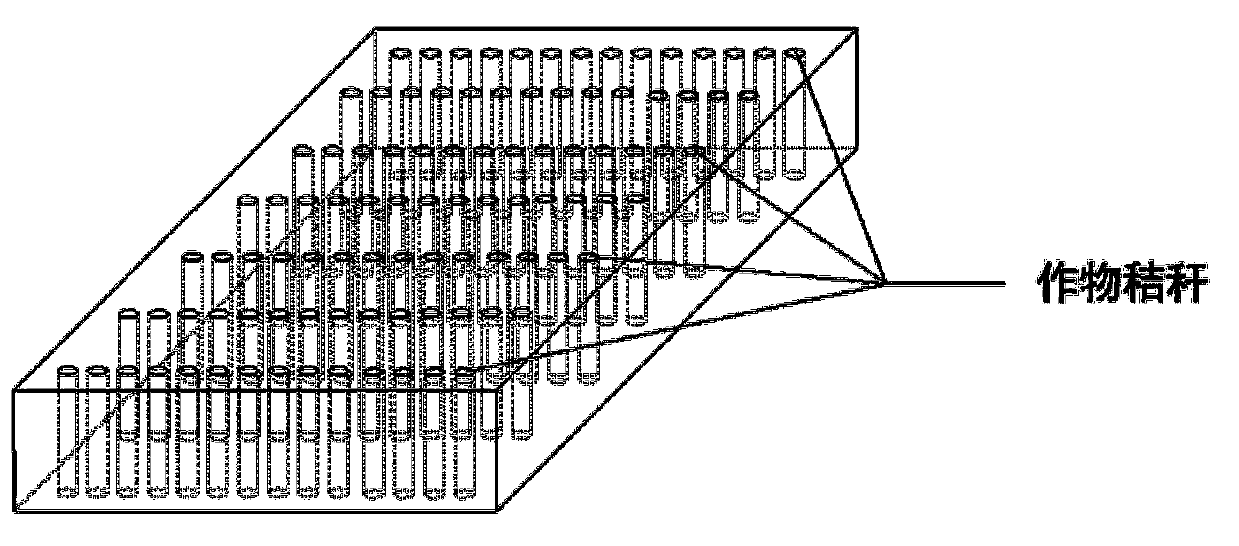

[0042] ③ Preparation of ecological prefabricated blocks

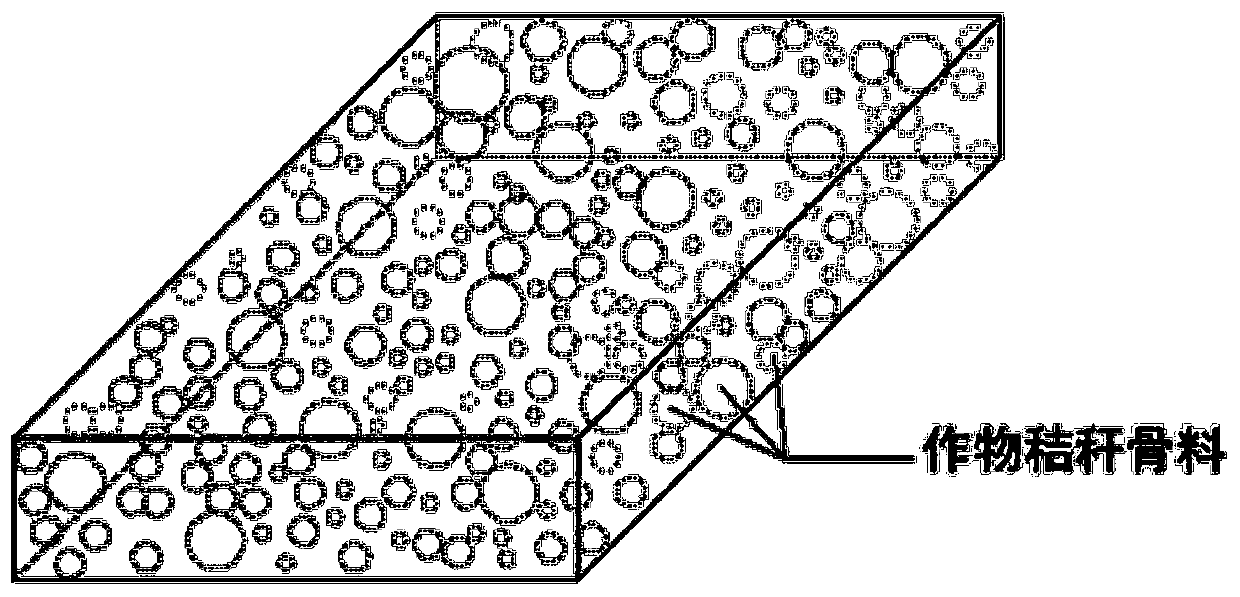

[0043] a. Drying, extruding and cutting the plant straw into granules to make aggregates with particle sizes of 5~10mm, 10~15mm and 15~20mm;

[0044]b. Spray water on the surface of straw aggregate 2~3 times, mix 2 parts by mass of straw aggrega...

Embodiment 2

[0052] ① Preparation of curing agent for ecological slope protection prefabricated blocks

[0053] Mix 5 parts by mass of quicklime, 5 parts by mass of fly ash, 0.8 parts by mass of magnesium oxide and 2 parts by mass of calcium sulfate powder to obtain the curing agent required for the product.

[0054] ② Preparation of microbial envelopes

[0055] With 25 mass parts Trichoderma reesei Trichoderma reesei T131 bacterial agent and 10 parts by mass of Bacillus subtilis Bacillus subtilis Mix D9 microbial agent with 1 mass part of urea-formaldehyde resin liquid, add 0.3 mass part of coagulant ammonium chloride, stir evenly, spray granulate, and obtain microbial coating body.

[0056] ③ Preparation of ecological prefabricated blocks

[0057] a. Mix 80 parts by mass of curing agent with 270 parts by mass of dewatered river channel silt, add water according to the final water-to-binder ratio of 0.35, add 3 parts by mass of microbial coatings, and stir evenly to obtain the ecolo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com