Polyurethane emulsion and antireflection coating liquid prepared from polyurethane emulsion

A technology of polyurethane emulsion and coating solution, which is applied in polyurea/polyurethane coatings, reflective/signal coatings, coatings, etc., and can solve problems such as poor abrasion resistance and weather resistance of coatings, and restrictions on the use of polyurethane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] Prepare polyurethane emulsion, the steps are as follows:

[0096] 1) Take 89.47g of PPG6000 (two functional groups) after vacuuming to remove water (Dow Chemical, hydroxyl content 0.03mol), 33.6g isophorone diisocyanate (Wanhua Chemical, NCO content 0.3mol), catalyst dilauric acid 0.020 g of dibutyltin was added to the reactor, and mixed and stirred at 50° C. for 2 hours.

[0097] 2) Dissolve 18.52g of chain extender 2,2-dimethylolbutanoic acid (hydroxyl content: 0.25mol) into 92.83g of solvent N-methylpyrrolidone, then slowly add to the above solution, at a temperature of 50°C, The reaction was continued for 2 hours.

[0098] 3) Add neutralizing agent ammonia 17.52g (25% concentration) to above-mentioned solution, after stirring evenly, then add it into 1074.14g deionized water emulsification and obtain the nano polyurethane emulsion of solid content 12%.

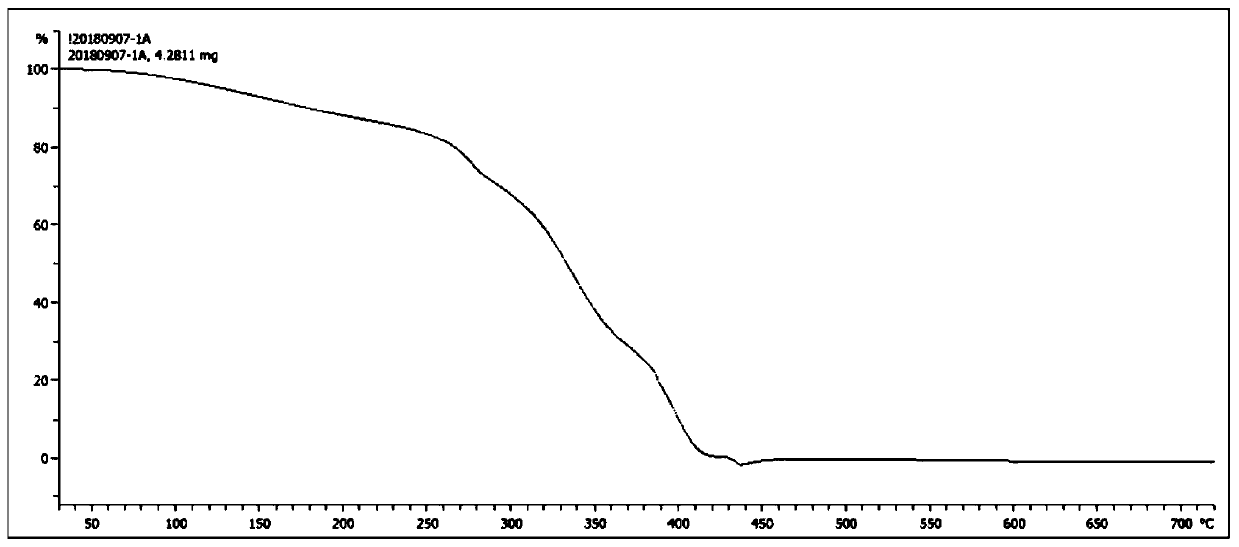

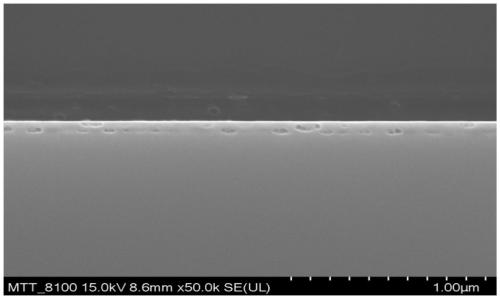

[0099] Its particle size was tested to be 100nm. The thermal decomposition residual rate of the polyurethane e...

Embodiment 2

[0104] Prepare polyurethane emulsion, the steps are as follows:

[0105] 1) Take 14.83g of polyether polyol PPG-600 (2 functional groups) after vacuuming to remove water (Dow Chemical, hydroxyl content 0.05mol), 25.07g diphenylmethane diisocyanate (BASF M20S, NCO content 0.2mol), The catalyst, 0.024 g of dibutyltin diacetate, was added to the reactor, and mixed and stirred at 50° C. for 4 hours.

[0106] 2) Dissolve 55.56g of chain extender 2,2-dimethylolbutanoic acid (0.75mol of hydroxyl content) into 78.51g of solvent propylene glycol butyl ether, then slowly add to the above solution, and continue the reaction at a temperature of 50°C 2 hours.

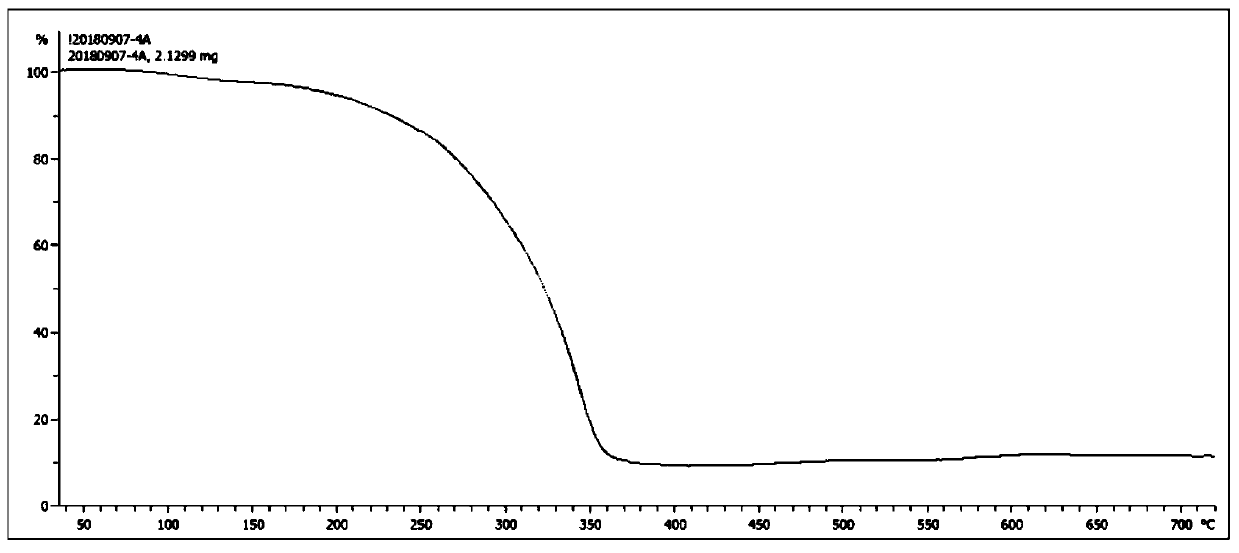

[0107] 3) Add neutralizing agent 105.16g ammonia water (25% concentration) to above-mentioned solution, after stirring evenly, then add it into 593.21g deionized water emulsification and obtain the nano polyurethane emulsion of solid content 23%. Its particle size was tested to be 50nm. The thermal decomposition residual rate was...

Embodiment 3

[0112] 1) Take 124.12g of polyether polyol PPG-2000 (two functional groups) after vacuuming to remove water (Dow Chemical, hydroxyl content 0.125mol), 428.57g of hexamethylene diisocyanate-based polyisocyanate (Wanhua Chemical HT-90B , NCO content 2mol), 0.1934g of catalyst tin octoate was added into the reactor, and mixed and stirred at 50°C for 2 hours.

[0113] 2) Dissolve 37.04g of chain extender 2,2-dimethylolbutanoic acid (hydroxyl content: 0.5mol) into 377.09g of solvent ethyl acetate, then slowly add to the above solution, and continue the reaction at a temperature of 50°C 2 hours.

[0114] 3) Add 10 g of neutralizing agent sodium hydroxide to the above solution, stir evenly, then add it into 2452.12 g of deionized water for emulsification to obtain a nano polyurethane emulsion with a solid content of 17.5%.

[0115] Its particle size was tested to be 80nm. The thermal decomposition residual rate was tested by thermogravimetric analysis equipment, and the residual ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com