Self-adhesive corona-resistant polyimide paint, enameled wire and preparation method thereof

A technology of polyimide paint and polyimide, which is applied in the direction of cable/conductor manufacturing, primer, circuit, etc., can solve the problems of lack of international competitiveness and lack of competitive advantage, achieve good application prospects, and improve electrical resistance Halo and other performance, the effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

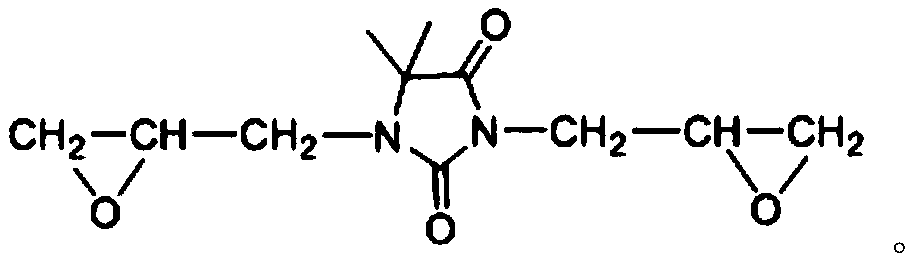

Method used

Image

Examples

Embodiment 1

[0066] With 100g of Heine epoxy resin, 500g of N,N,N',N'-tetraglycidyl-2,2-bis[4-(4-aminophenoxy)phenyl]propane TGBAPP, 50g Add 4,4'-diaminodiphenylsulfone into the reaction kettle, stir, heat up to 70°C-80°C, stir and react for 0.5 hours, add 300g of CE793 epoxy resin, stir well, cool to room temperature, add 30g m-xylylenediamine, and mix well at room temperature to obtain self-adhesive paint, denoted as SA-1.

[0067] 100g of Heine epoxy resin, 800g of N,N,N',N'-tetraglycidyl-2,2-bis[4-(4-aminophenoxy)phenyl]propane TGBAPP, 80g of Add 4,4'-diaminodiphenylsulfone into the reaction kettle, stir, heat up to 70°C-80°C, stir and react for 1 hour, add 600g of CE793 epoxy resin, stir well, cool to room temperature, add 20g m-xylylenediamine, and mix well at room temperature to obtain self-adhesive paint, denoted as SA-2.

[0068] 100g of Heine epoxy resin, 1000g of N,N,N',N'-tetraglycidyl-2,2-bis[4-(4-aminophenoxy)phenyl]propane TGBAPP, 100g of Add 4,4'-diaminodiphenylsulfone i...

Embodiment 2

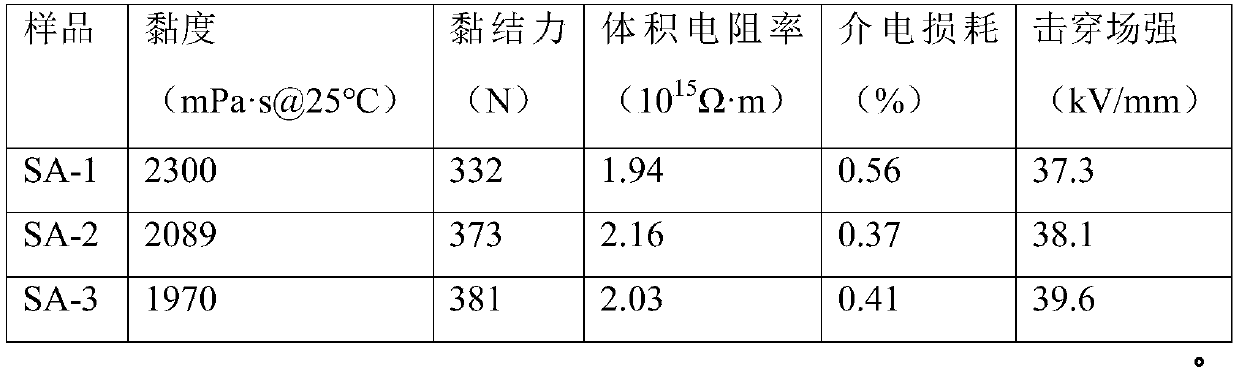

[0070]The performance test of the self-adhesive paint in Example 1, including viscosity, cohesive force, volume resistivity of the cured product, dielectric loss of the cured product, and breakdown field strength of the cured product, the specific test results are shown in Table 1, and the test method is as follows:

[0071] 1. Viscosity test

[0072] The CAP2000+ viscometer produced by Brookfield Corporation of the United States was used for testing, the rotor was selected as No. 1, and the temperature range was 25 °C.

[0073] 2. Adhesion test

[0074] The wound spiral copper wire is immersed in the self-adhesive paint, cured at 180°C for 1 hour, and the adhesion test is carried out by a computer-controlled electronic universal testing machine. Three samples are tested for each formula, and then the average value is taken.

[0075] 3. Volume resistivity test

[0076] Apply the self-adhesive paint evenly to a circular mold with a diameter of 110mm, solidify at 180°C for 1 h...

Embodiment 3

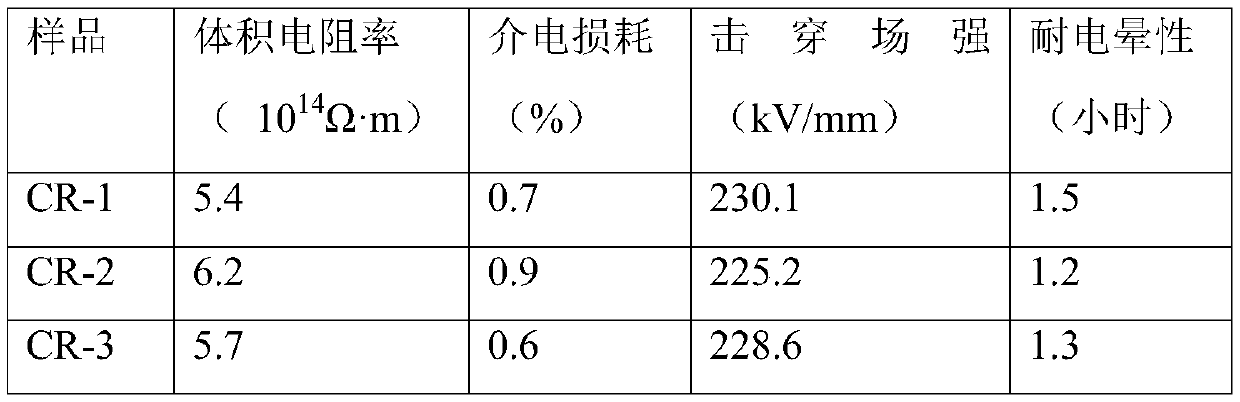

[0085] 19.8g (0.1mol) of 4,4'-diaminodiphenylmethane, 26.0g (0.13mol) of 3,4'-diaminodiphenyl ether and 36.6g (0.1mol) of 2,2-bis( 3-Hydroxy-4-aminophenyl) aromatic dibasic primary amine of hexafluoropropane, 400.0 g of N,N-dimethylformamide and 232.8 g of N-methyl-2-pyrrolidone Add the protic organic solvent into the reaction kettle, stir and dissolve at room temperature, add 43.6g (0.2mol) of pyromellitic dianhydride and 32.2g (0.1mol) of 3,3',4,4'-tetracarboxydiphenyl Aromatic dibasic anhydride of ketone dianhydride, stirring and reacting at room temperature for 1 hour, adding 69.1 g of 3-aminopropyltrimethoxysilane coupling agent-treated silica inorganic nanopowder and 10.0 g of 3-ammonia The titanium dioxide inorganic nanopowder treated with propyltrimethoxysilane coupling agent was stirred and ground evenly to obtain 870.1 g of corona-resistant polyimide paint, which was designated as CR-1.

[0086] 23.0g (0.115mol) of 4,4'-diaminodiphenyl ether, 20.0g (0.1mol) of 3,4'-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com