Degradable air bubble film and preparation process thereof

A bubble film, biodegradable technology, used in sustainable manufacturing/processing, flat products, climate sustainability, etc. Impact and other issues, to reduce adverse effects, increase durability, and increase the effect of contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

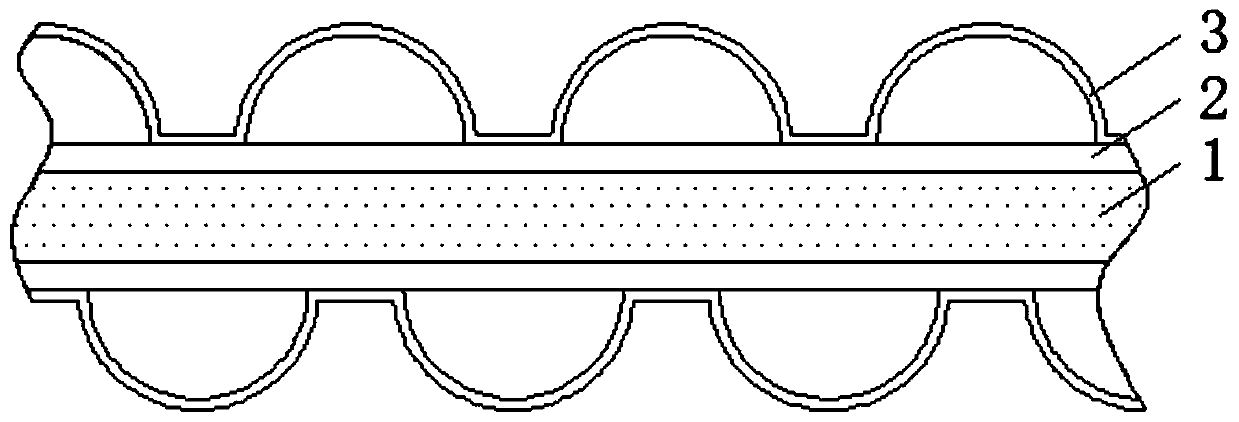

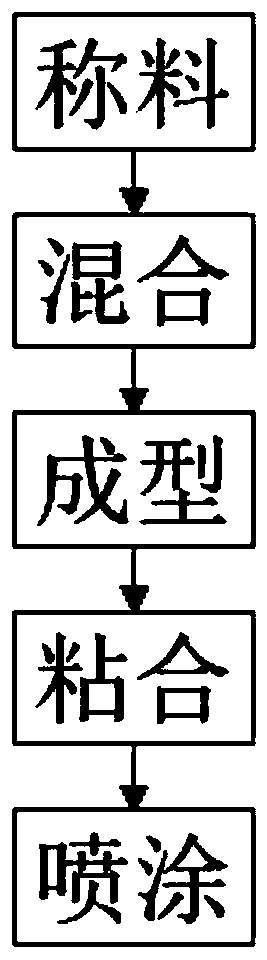

[0027] Such as Figure 1-2 As shown, the present invention provides a kind of technical scheme: a kind of degradable air bubble membrane, comprises base layer 1, and base layer 1 is the grid surface that bamboo charcoal fiber weaves, and the weight part is 60-70 parts, uses bamboo charcoal fiber weave by setting The formed grid surface enables the present invention to improve the toughness and strength of the present invention under the premise of reducing pollution, so that the use effect of the present invention is better. The front and back sides of the base layer 1 are fixedly connected with the bubble film layer 2. Adopting the structure of one layer of base layer 1 and two layers of air bubble film layer 2 can make the present invention have better use strength. The position of the bubbles in the upper and lower bubble film layers 2 is stagg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com