Method and system for preparing lactic acid by using biological fermentation technology to produce high-yield and high-optical purity lactide

A bio-fermentation and lactide technology, applied in the field of fermentation biology and biodegradable materials, can solve the problems of many by-products, low reaction efficiency, low yield, etc., reduce the requirement of vacuum level, ensure continuous production, The effect of improving the comprehensive yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] In the present invention, preferably, the preparation method of the seed solution comprises: picking a single colony of the Lactobacillus rhamnosus and inoculating it in a seed medium for seed culture to obtain the seed solution.

[0067] In the present invention, in order to increase the yield of lactic acid, preferably, relative to 100 parts by volume of the acidogenic fermentation medium, the inoculation amount of the seed liquid is 5-10 parts by volume.

[0068] In the present invention, the lactic acid in the obtained fermentation broth can be separated by known methods, for example, the cells in the fermentation broth are removed first, and then the fermented broth after cell removal is concentrated to crystallize the product, or ion exchange layer Lactic acid is separated by analysis and the like.

[0069] In the present invention, the lactic acid in the fermentation broth or the lactic acid separated from the fermentation broth can also be detected by known meth...

Embodiment approach

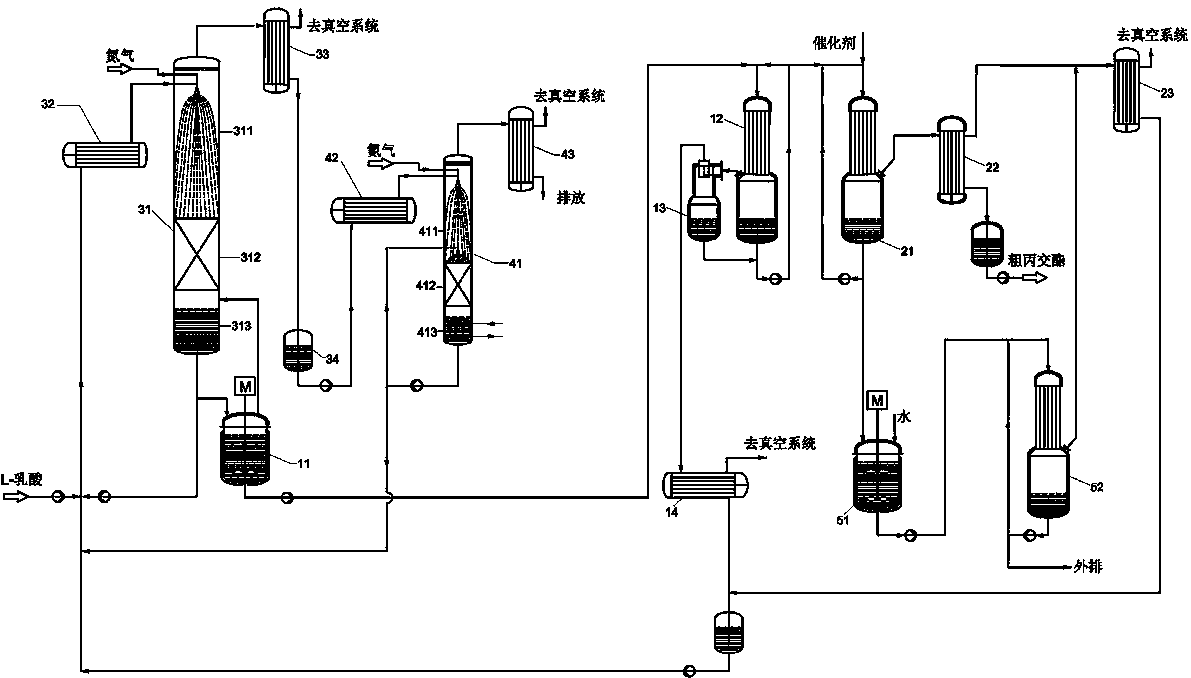

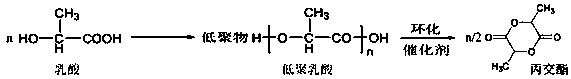

[0082] According to a preferred embodiment of the present invention, the lactic acid is obtained by primary concentration of lactic acid raw materials with a water content of less than 10% by weight in a primary concentration tower. Wherein, the first-stage concentration tower includes a first-stage atomized rectification section, and the first-stage atomized rectification section is an empty barrel (a section of empty barrel without packing or tray), and the first-stage concentrated Methods include:

[0083] (i) heating lactic acid feedstock with a water content of less than 10% by weight to 90-120°C, preferably 105-120°C;

[0084] (ii) introducing the heated lactic acid raw material in the form of mist into the primary atomized rectification section for flash evaporation to obtain the first dehydrated lactic acid mist and flash steam, wherein the flash steam contains water vapor and lactic acid vapor;

[0085] (iii) During the falling of the first dehydrated lactic acid dro...

preparation example

[0172] Pick a single colony of Lactobacillus rhamnosus strain CGMCC No. 19057 and inoculate it in MRS liquid medium, cultivate overnight at 37°C and 150rpm to obtain OD 600 12 for the seed solution. Then, the above seed solution was inoculated in the acidogenic fermentation medium at a ratio of 10% (v / v), and cultured at 37°C and 150 rpm for 6 hours to allow the strain to grow, then the temperature was raised to 48°C, and the shaker culture was continued at 150 rpm for 42 Hours to obtain fermentation broth (total fermentation time 48 hours). First remove the cells in the fermentation broth, then separate the lactic acid, and concentrate to obtain lactic acid with a water content of less than 10% by weight, and the optical purity of L-lactic acid is above 95%.

[0173] (2) The system for producing lactide of the present invention, the system comprising:

[0174] A. Lactic acid concentration unit, described lactic acid concentration unit comprises:

[0175] l One-stage concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com