Non-dissolution type antibacterial finishing agent and preparation method thereof

The technology of antibacterial finishing agent and mixed solvent is applied in the field of non-dissolving antibacterial finishing agent and its preparation, which can solve the problems affecting the appearance, color, high MIC value of bacteria, and affecting combat effectiveness of clothing and accessories, and achieves obvious antibacterial effect. The effect of high chemical stability and low biological toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

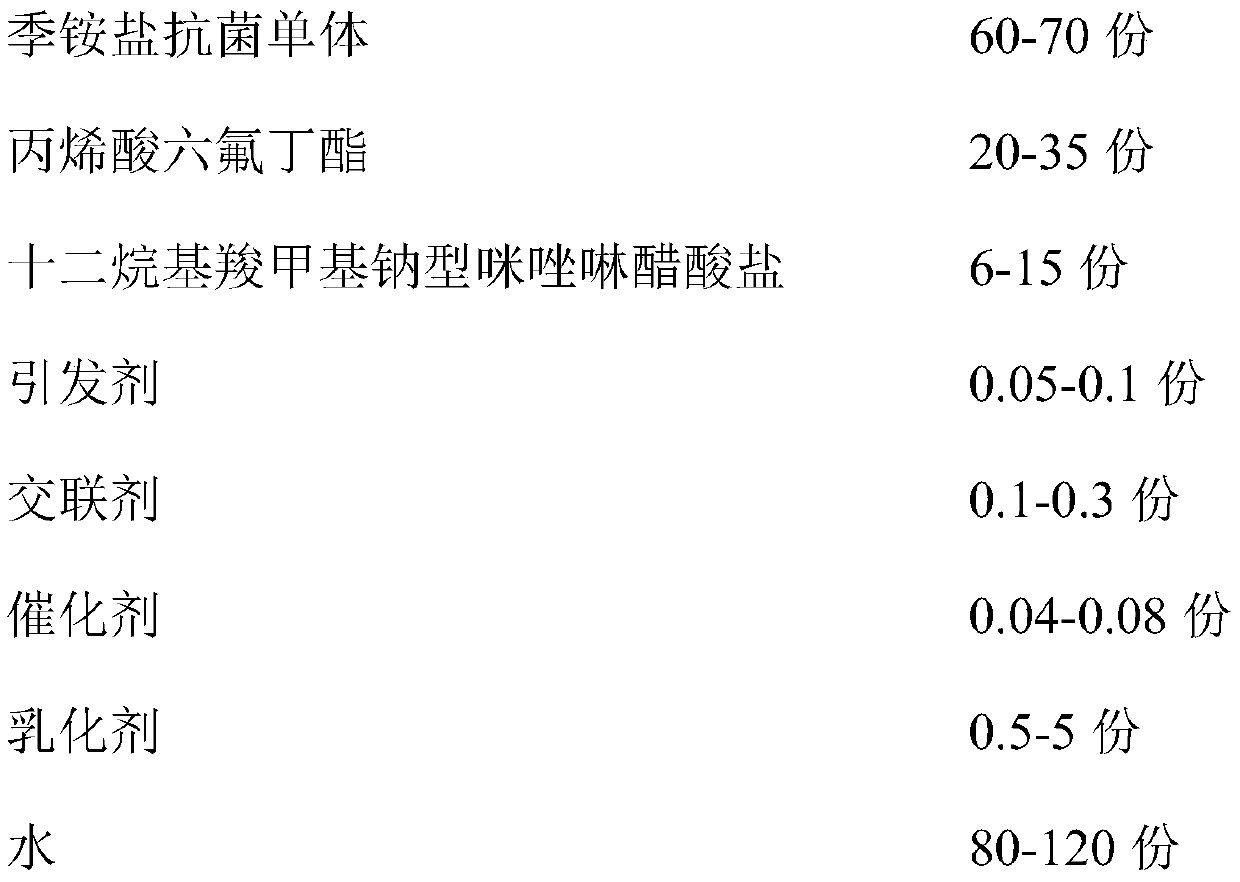

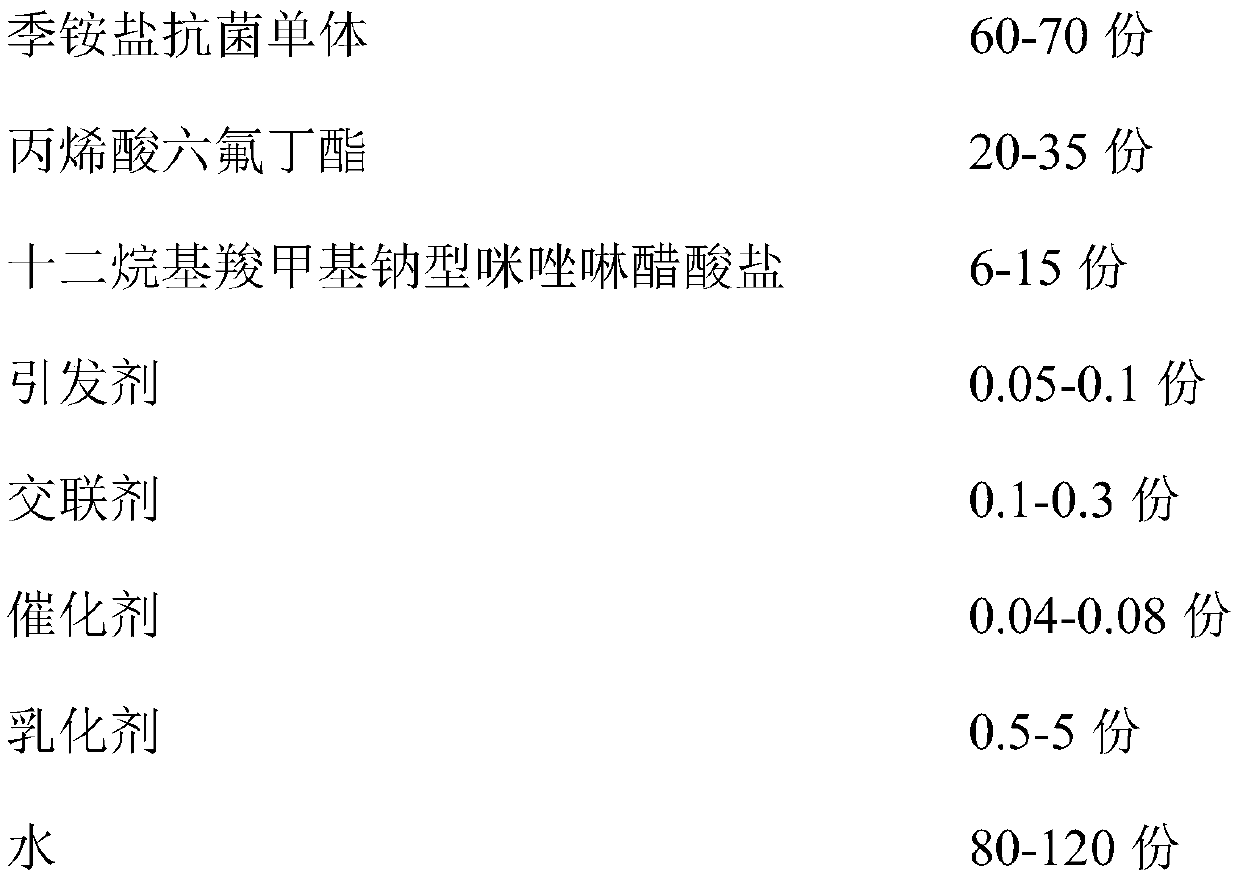

[0029] A non-elution type antibacterial finishing agent, comprising: 65 parts of quaternary ammonium antibacterial monomers, 32 parts of hexafluorobutyl acrylate, 12 parts of sodium dodecyl carboxymethyl imidazoline acetate in parts by weight, 0.05 parts of 2,2-azobis(2-methylpropylimidium) dihydrochloride, 0.1 parts of N,N-methylenebisacrylamide, 30.04 parts of TiCl4-Al(C2H5), 2 parts of emulsifier, 100 parts of water;

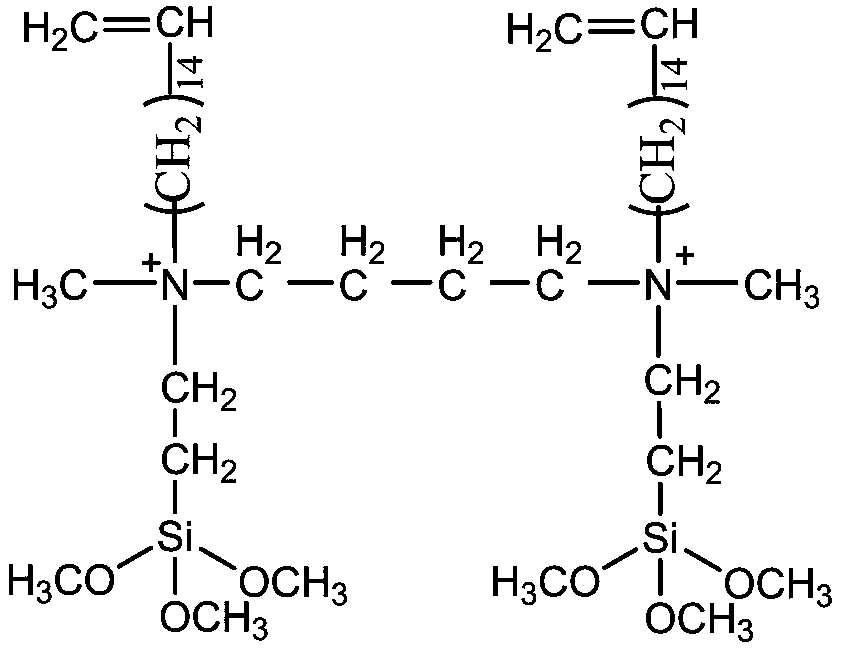

[0030] Described quaternary ammonium salt antibacterial monomer obtains by following preparation method:

[0031] (1) Add 11-bromo-1-undecene and tetramethyl-1,4-butanediamine with a substance ratio of 2.05:1 into an enamel reactor with a condensation reflux device and mix evenly, then add Solvent isopropanol and hydroquinone, heat and reflux at 95°C for 24 hours, spin off the solvent, extract and wash with ether to remove the polymerization inhibitor and unreacted long-chain halogenated olefin, and obtain the gemini quaternary ammonium salt;

[0032] (2) A...

Embodiment 2

[0037] A non-elution type antibacterial finishing agent, comprising: 70 parts of quaternary ammonium salt antibacterial monomer, 35 parts of hexafluorobutyl acrylate, 8 parts of dodecyl carboxymethyl sodium imidazoline acetate, 0.06 parts of azobisisobutyronitrile, 0.2 parts of N,N-methylenebisacrylamide, 30.08 parts of TiCl4-Al(C2H5), 5 parts of emulsifier, and 120 parts of water;

[0038] Described quaternary ammonium salt antibacterial monomer obtains by following preparation method:

[0039] (1) Add 16-bromo-1-hexadecene and tetramethyl-1,4-butanediamine with a substance ratio of 2.1:1 into the enamel reaction kettle with a condensation reflux device and mix evenly, then add Solvent isopropanol and hydroquinone, heat and reflux at 100°C for 30 hours, spin off the solvent, extract and wash with ether to remove the polymerization inhibitor and unreacted long-chain halogenated olefin, and obtain the gemini quaternary ammonium salt;

[0040] (2) Add β-chloroethyltrimethoxysilan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com