Flexible lithium-sulfur battery and preparation method thereof

A lithium-sulfur battery, flexible technology, applied in lithium batteries, battery electrodes, secondary batteries, etc., can solve the problems of fiber electrode film size limitation, uncontrollability, difficulty in forming sulfur loading rate sulfur fiber electrodes, etc., and achieve excellent electrical stability The effect of flexible and flexible bending properties, good electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a method for preparing a flexible lithium-sulfur battery, comprising the following steps:

[0029] heat-treating the sulfur with the modified material to obtain a sulfur composite material; the modified material includes one or more of transition metal carbides, manganese dioxide, graphene and porous carbon;

[0030] mixing and dispersing the sulfur composite material, carbon nanotubes, surfactant and water to obtain a spinning stock solution;

[0031] Using the spinning stock solution to prepare fiber filaments by a coagulation bath spinning method, removing the coagulation bath solution components in the fiber filaments to obtain long-fiber sulfur carbon positive electrodes;

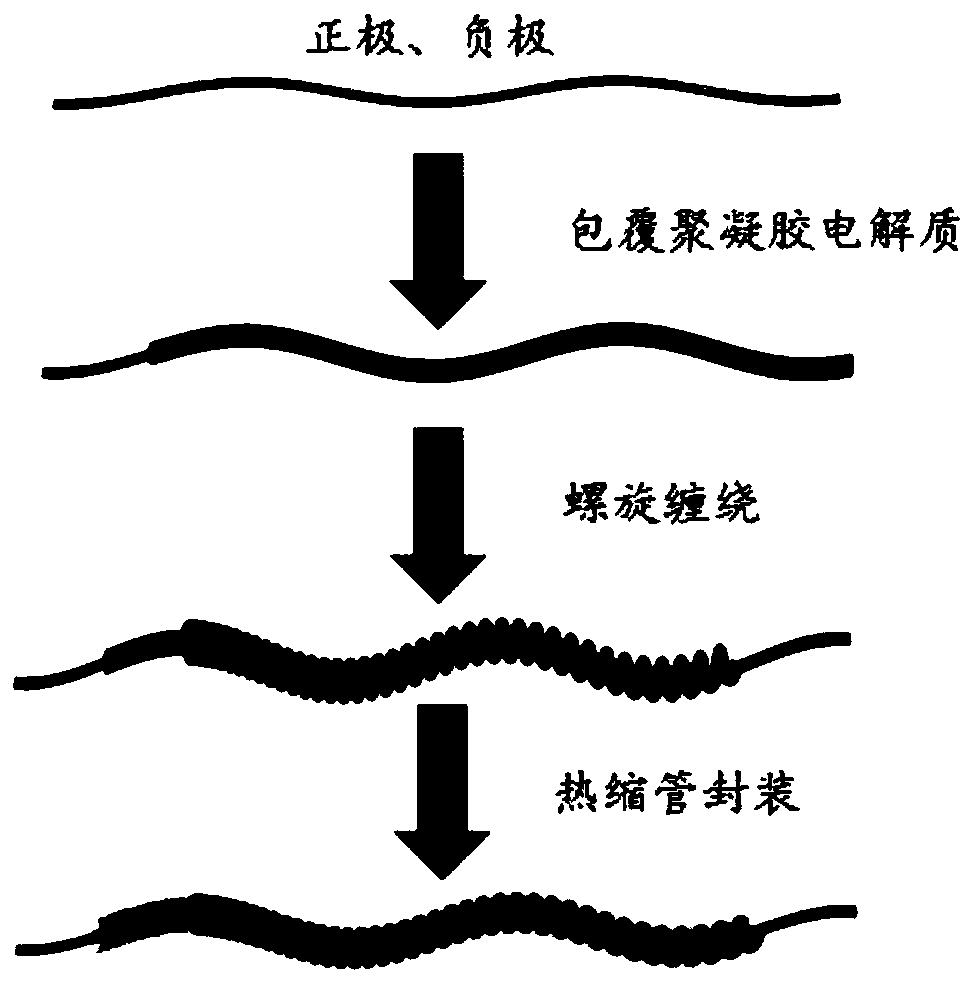

[0032] Coating the surfaces of the long-fiber sulfur-carbon positive electrode and the lithium metal wire negative electrode with a polygel electrolyte, respectively, to obtain a coated positive electrode and a coated negative electrode;

[0033] The coated positive elect...

Embodiment 1

[0059] According to sulfur accounting for 70% of the total mass of sulfur and the modified material, the modified material MXene (selected Ti 3 C 2 ) and sulfur element in a mortar, put it into a glass tube filled with argon, seal it, and heat-treat it in a tube furnace at 155°C for 48 hours to obtain a sulfur composite material;

[0060] According to the mass ratio of sulfur composite material and carbon nanotubes as 3:1, and the mass ratio of carbon nanotubes and surfactant as 1:5, the obtained sulfur composite material, carbon nanotubes, surfactant sodium deoxycholate and deionized Mix with water, and then ultrasonically disperse with a 500W probe to obtain a spinning dope with a solid content of 1%;

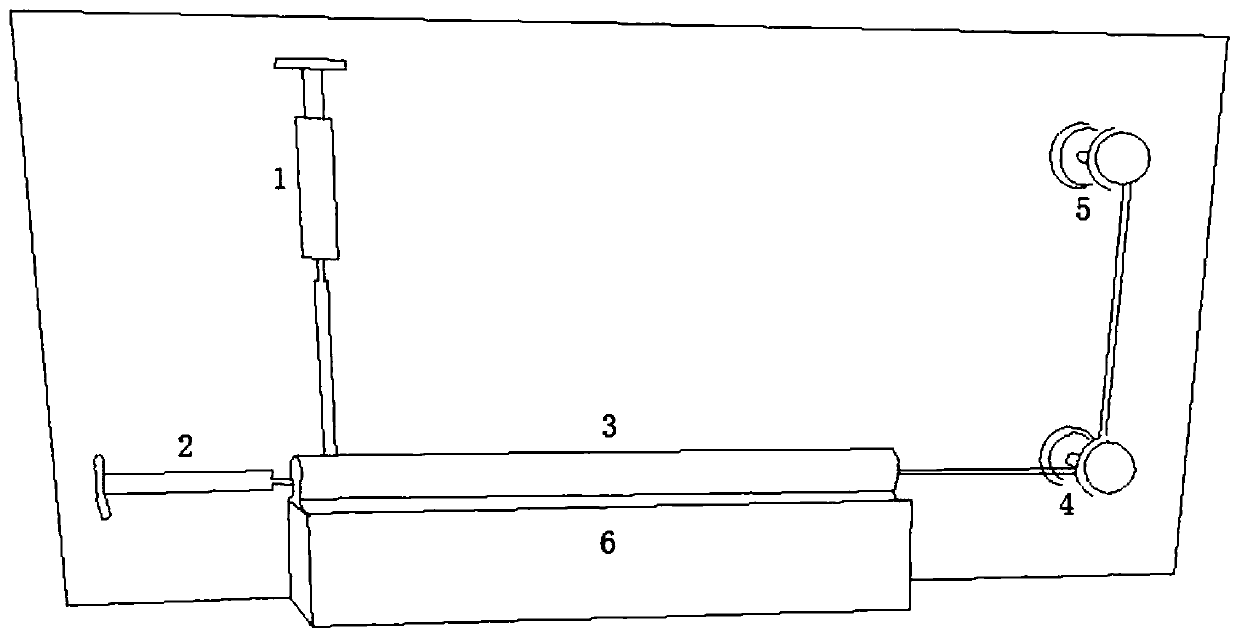

[0061] Take chitosan acetic acid solution as coagulation bath solution, wherein the massfraction of chitosan is 5%, and the massfraction of acetic acid is preferably 1%; figure 1 Spinning equipment with the structure shown, put the spinning stock solution and the coagulatio...

Embodiment 2

[0066] According to the fact that sulfur accounts for 80% of the total mass of sulfur and modified materials, the modified material graphene and sulfur element are mixed in a mortar, put into a glass tube filled with argon, and heat-treated in a tube furnace at 155°C for 48 hours after sealing. Obtain sulfur composite material;

[0067]According to the mass ratio of sulfur composite material and carbon nanotubes as 4:1, and the mass ratio of carbon nanotubes and surfactant as 1:5, the obtained sulfur composite material, carbon nanotubes, surfactant dodecane and deionized water were Mix, and then ultrasonically disperse with a 500W probe to obtain a spinning dope with a solid content of 2%;

[0068] Take chitosan acetic acid solution as coagulation bath solution, wherein the mass fraction of chitosan is 8%, the mass fraction of acetic acid is preferably 1%; Inject the spinning stock solution and coagulation bath solution into a glass tube with an inner diameter of 40 μm throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com