Method for photocatalytic selective ester aminolysis of epoxy grease

An epoxy grease, a selective technology, applied in the field of polymers, can solve the problems of difficult degradation, poor mechanical properties, application limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

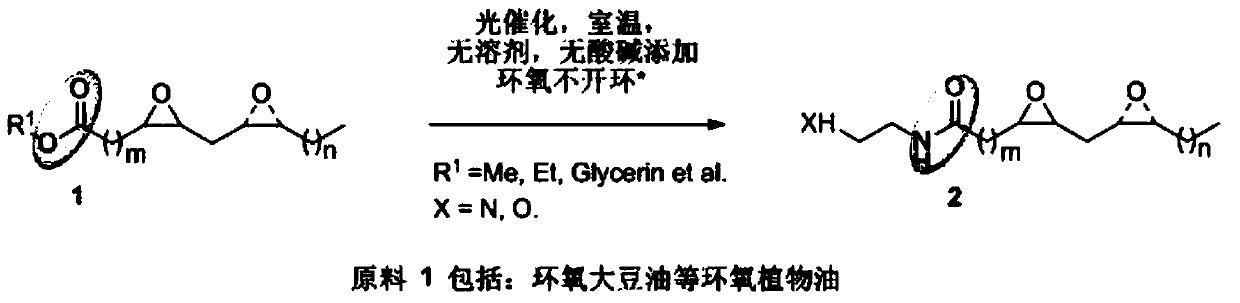

Embodiment 1

[0032] This embodiment provides a method for preparing epoxy resin by selective ester aminolysis of photocatalytic epoxy grease, comprising: taking epoxy vegetable oil as raw material, adding imine and photocatalyst, and reacting under the irradiation of white LED lamp to obtain the target product, Its synthetic route is as follows image 3 shown. In the above reaction, the epoxidized soybean oil, ethanolamine, Ru(bpy) 3 2+ The molar ratio is (0.5~1.2):(0.4~0.6):(0.1~0.2).

[0033] In the above reaction, the reaction is carried out in a solvent-free, acid-base-free system.

[0034] In the above reaction, the reaction was carried out under the protection of an inert gas and irradiated continuously for 8 hours.

Embodiment 2

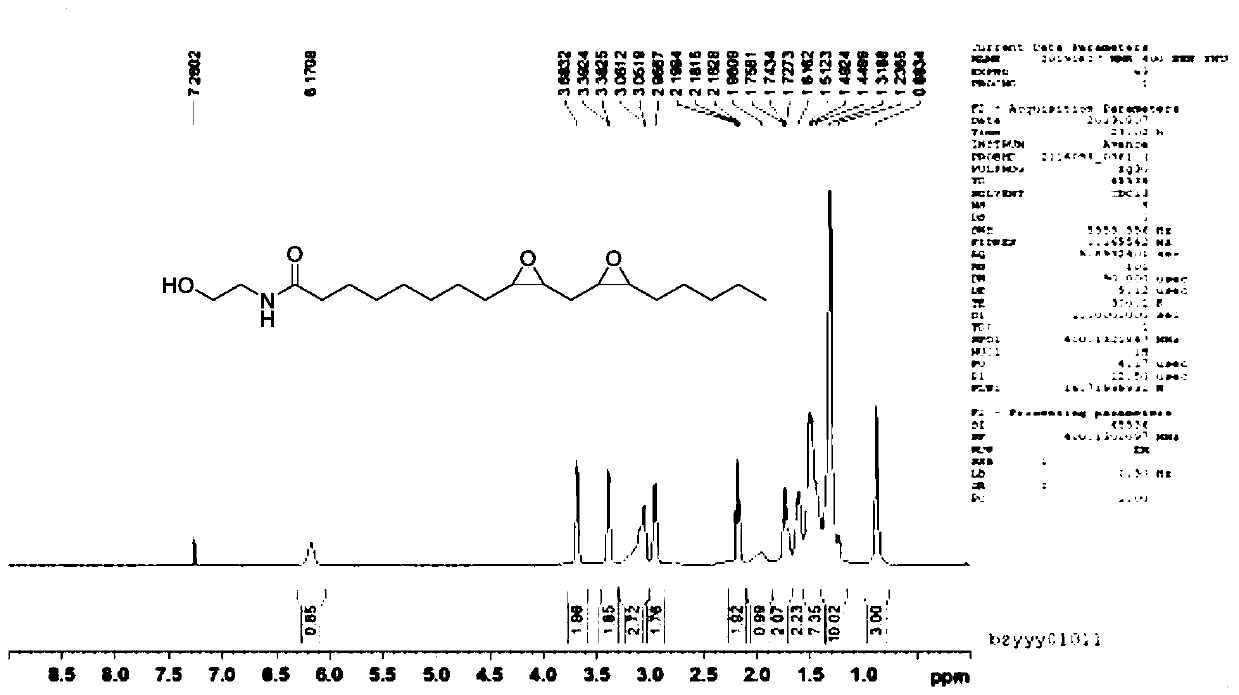

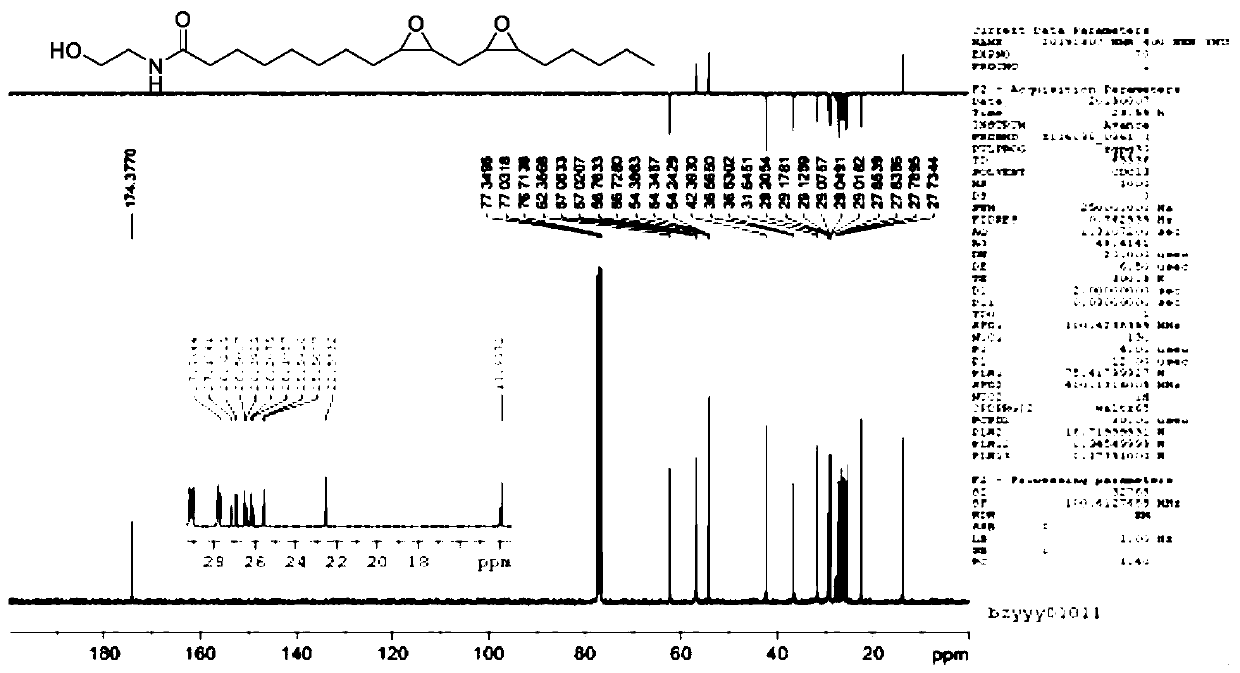

[0036] The present embodiment provides a kind of photocatalyzed method for selective ester aminolysis of epoxy grease, with epoxy ethyl linoleate (0.33g, 1.0mmol), ethanolamine (2.53g, 4.1mmol), Ru (bpy) 3 2+ (0.1mmol) was added to a dry 25mL round bottom flask, under the conditions of no solvent and no addition of acid and alkali, the reaction system was protected by an inert gas and continuously irradiated for 8h under a white LED lamp. During the reaction, thin layer chromatography (TLC ) to monitor the progress of the reaction.

[0037] Post-reaction treatment: monitor the reaction process in real time with a thin-layer chromatography plate. After 8 hours, the raw material ethyl epoxy linoleate basically reacts completely, and the reaction is stopped. Then the reaction solvent was poured into a 250mL separatory funnel, extracted with dichloromethane (3×10mL) and water (3×10mL), the lower organic phase was collected, dried over anhydrous magnesium sulfate, filtered and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com