Continuous ion exchange system for xylose production and using method thereof

A continuous ion exchange system technology, which is applied in the field of continuous ion exchange system for xylose production, can solve the problems of large amount of regenerant and purified water, large manual operation error, and low utilization rate of resin, so as to reduce the regeneration of chemical reagents The effect of dosage, reducing environmental protection pressure and improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1, the production and refining of decolorizing liquid

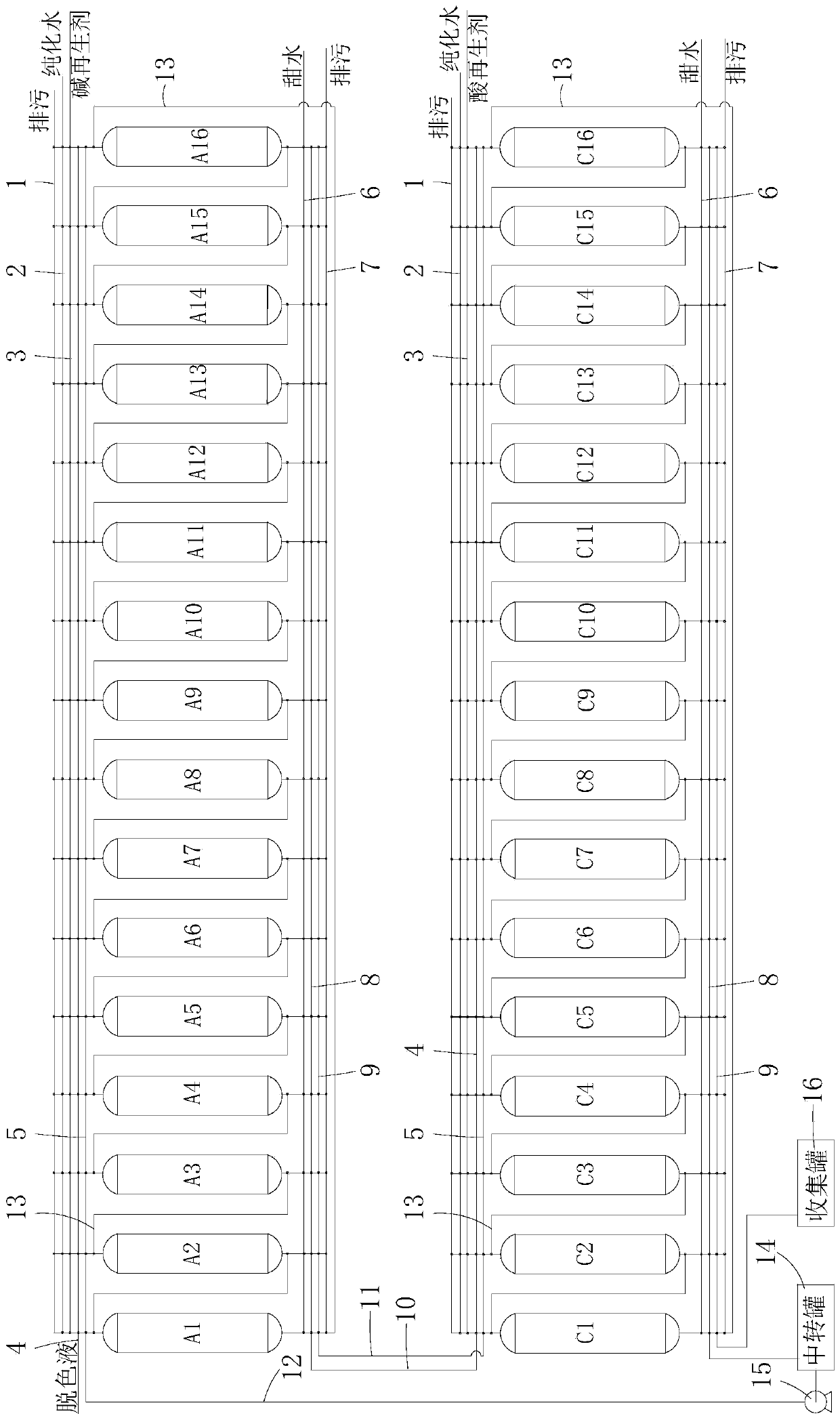

[0047] Please refer to figure 2 As shown, the xylose decolorizing solution to be treated by ion exchange has a refractive index of 8%, a light transmittance of 60%, and an electrical conductivity of 8000 μs / cm.

[0048] The two groups of ion exchange resins are macroporous strong acid cation exchange resin and macroporous weak base anion exchange resin respectively, and the feed flow is controlled at 5m 3 / h, the flow direction of feed liquid is negative column production 3 (A6) → negative column production 2 (A5) → negative column production 1 (A4) → positive column production 3 (C6) → positive column production 2 (C5) → positive column Column production 1 (C4) → transfer tank → negative column refining 2 (A3) → negative column refining 1 (A2) → positive column refining 2 (C3) → positive column refining 1 (C2) → collection tank. Finally, the xylose liquid after ion exchange treatment has a refractive...

Embodiment 2

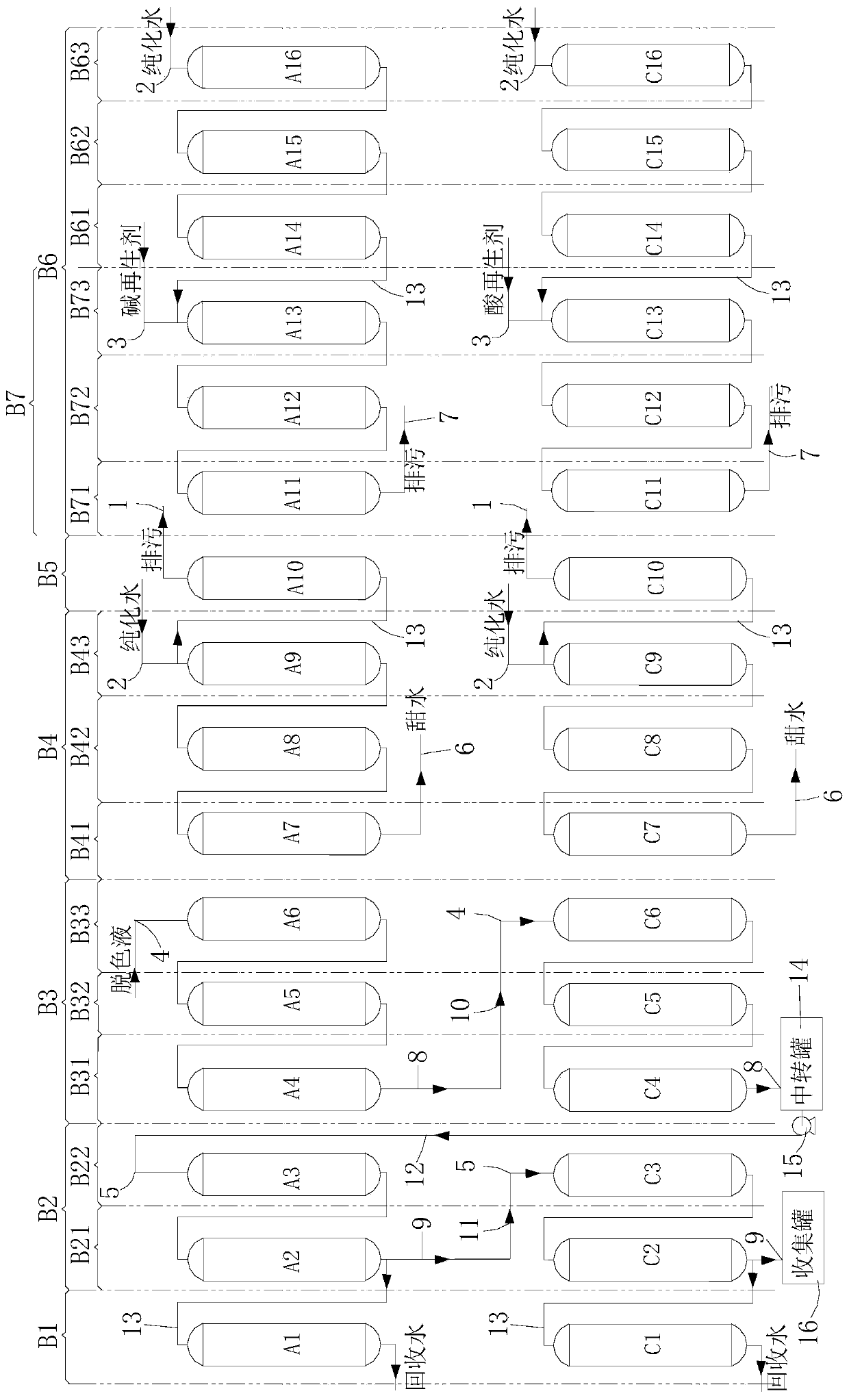

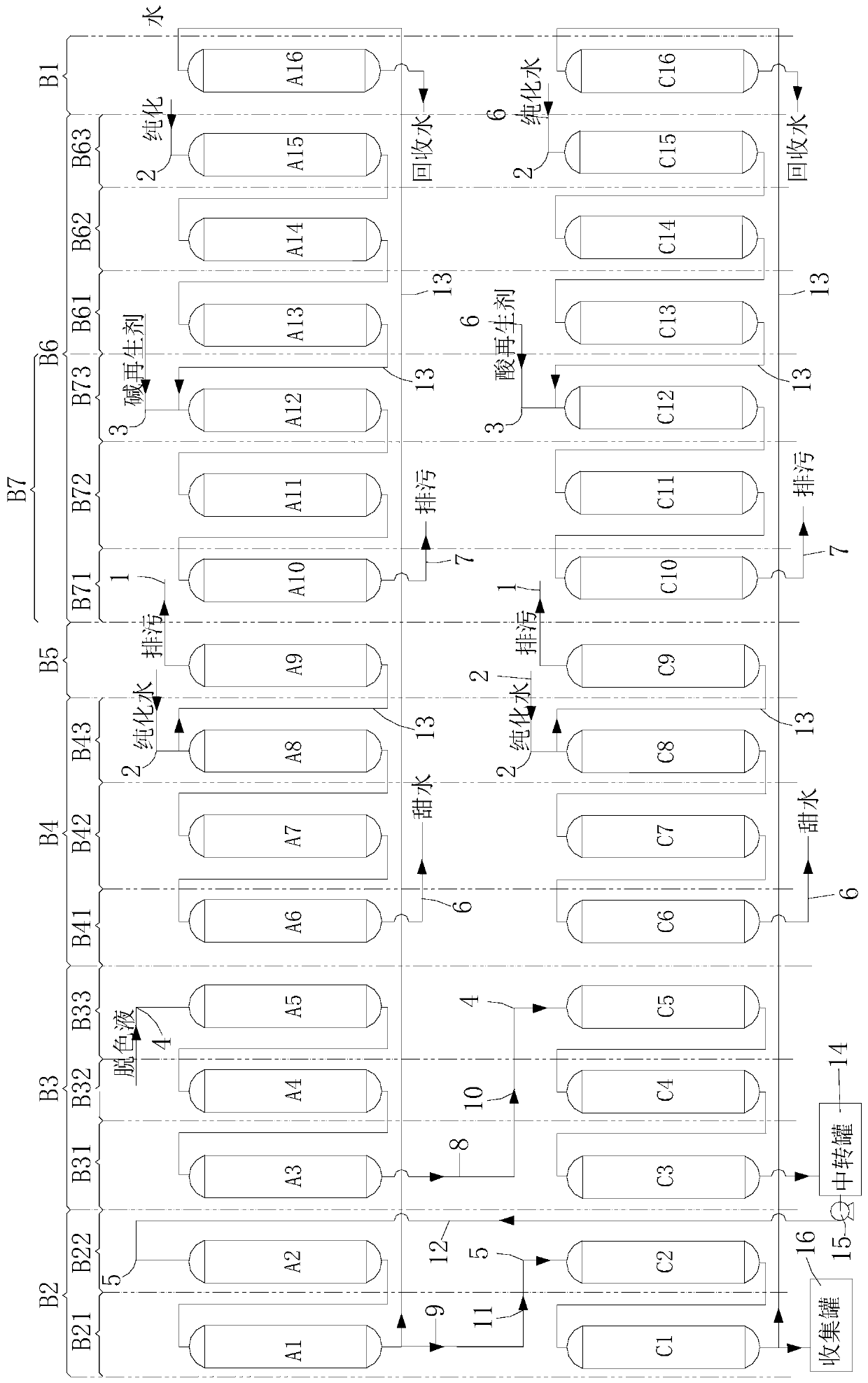

[0055] Embodiment 2, the regeneration process of ion exchange column

[0056] First, water is passed into the resin column in the backwash stage, and the used resin is backwashed to remove suspended impurities. At the same time, the purified water is changed from rinsing 3 (A16 / C16) → rinsing 2 (A15 / C15) → rinsing 1 (A14 / C14) → regeneration 3 (A13 / C13) → regeneration 2 (A12 / C12) → regeneration 1 ( A11 / C11) is used for sequential column-string cleaning. Since the cleaning runs in the column-string, the concentration of the regenerant in the cleaning water will gradually be the highest, which is to reuse the original regenerant in the column. After the column of elution 3 (A16 / C16) is cleaned, the regenerant is regenerated from the sequence of regeneration 3 (A13 / C13) → regeneration 2 (A12 / C12) → regeneration 1 (A11 / C11). In the regeneration process, the regenerant uses 3% hydrochloric acid solution and 3% sodium hydroxide solution.

[0057] Converting the amount of acid and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com