Preparation method of 2, 5-furandicarboxylic acid-based block copolyester

A technology of furandicarboxylic acid block and furandicarboxylic acid, which is applied in the field of polyester preparation, can solve the problems of the original performance decline of PEF copolyester, and achieve the effect of excellent thermodynamic performance, good hue, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

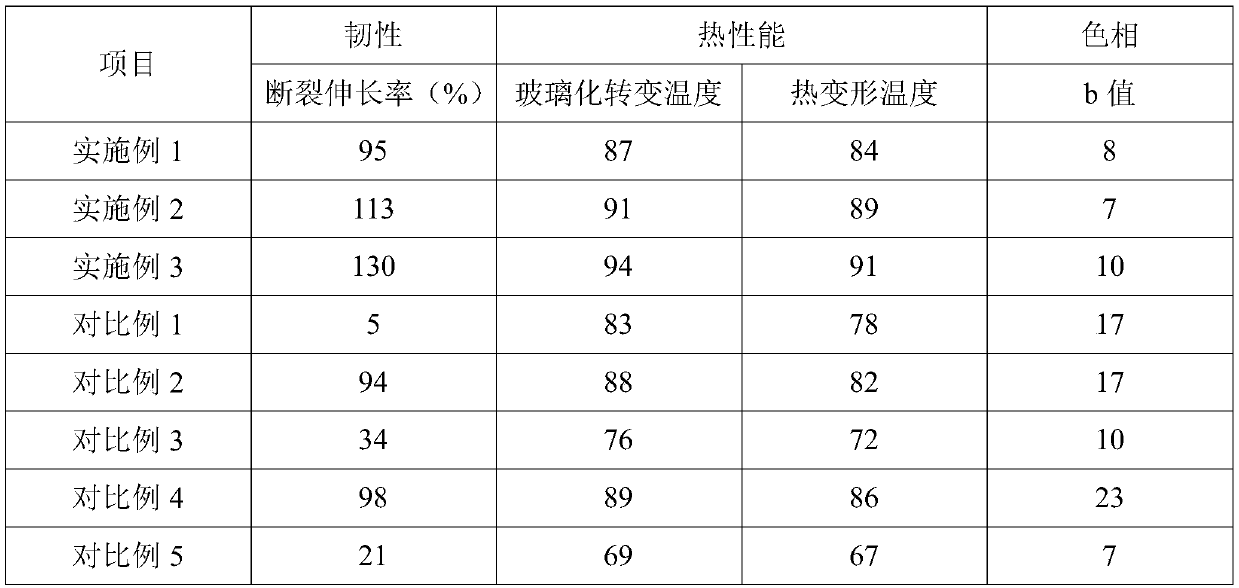

Examples

Embodiment 1

[0030] Embodiment 1: a kind of preparation method of 2,5-furandicarboxylate block copolyester, comprises following preparation steps:

[0031] 1) Mix 100g of 2,5-furandicarboxylic acid, 64g of ethylene glycol, 0.1g of catalyst, and 0.1g of stabilizer, and carry out esterification reaction at 195°C to prepare esterified product A;

[0032] 2) Mix 160g of 2,5-furandicarboxylic acid and 146g of thionyl chloride, and react at 60°C for 2 hours to prepare a halogenated furandicarboxylic acid;

[0033]3) Put 195g of furandicarboxylic acid halide, 161g of tetrahydrofuran dimethanol, 0.1g of isopropyl titanate and 0.1g of heat stabilizer 425 in the reaction kettle at room temperature and stir for 1 hour, stir evenly, then raise the temperature to 140°C within 1 hour, and Carry out esterification reaction under protective gas atmosphere to prepare esterified compound B;

[0034] 4) Insulate the esterified product B at 200°C and 1 Pa for 1 hour for precondensation reaction to prepare a ...

Embodiment 2

[0036] Embodiment 2: a kind of preparation method of 2,5-furandicarboxylate block copolyester, comprises following preparation steps:

[0037] 1) Mix 118g dimethyl 2,5-furandicarboxylate, 64g ethylene glycol, 0.1g catalyst, and 0.1g stabilizer, and carry out esterification reaction at 190°C to prepare esterified product A;

[0038] 2) Mix 200g of 2,5-furandicarboxylic acid and 320g of dibromothionyl sulfoxide, and incubate at 80°C for 1 hour to prepare the halogenated furandicarboxylic acid;

[0039] 3) Put 430g of furandicarboxylic acid halides, 275g of tetrahydrofuran dimethanol, 0.1g of stannous octoate and 0.1g of triethyl phosphite in the reaction kettle and stir for 2 hours at room temperature. Stir evenly, and then heat up to 160°C within 1.5 hours. Carry out esterification reaction under protective gas atmosphere to prepare esterified compound B;

[0040] 4) Insulate the esterified product B at 210°C and 200pa for 0.5h for precondensation reaction to prepare a prepoly...

Embodiment 3

[0042] Embodiment 3: a kind of preparation method of 2,5-furandicarboxylate block copolyester, comprises the following preparation steps:

[0043] 1) Mix 100g of 2,5-furandicarboxylic acid, 64g of ethylene glycol, 0.1g of catalyst, and 0.1g of stabilizer, and carry out esterification reaction at 200°C to prepare esterified product A;

[0044] 2) Mix 250g of 2,5-furandicarboxylic acid and 229g of thionyl chloride, and react at 70°C for 1.5h to prepare a halogenated furandicarboxylic acid;

[0045] 3) Put 306g of furandicarboxylic acid halides, 337g of 2,5-furandimethanol, 0.1g of magnesium acetate and 0.1g of diphenyltridecyl phosphite in the reactor at room temperature and stir for 1.5h, stir evenly, and then heat up within 1.3h To 150°C, carry out the esterification reaction under the protective gas atmosphere, and prepare the esterified compound B;

[0046] 4) The esterified product B was incubated at 205°C and 100pa for 0.7h for precondensation reaction to prepare a prepol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com