Microorganism universal immobilized fermentation device and application thereof

A technology of immobilized fermentation and fermentation equipment, applied in the field of fermentation, can solve problems such as loss of energy consumption, easy winding of the stirring shaft, etc., and achieve the effects of low price, improved fermentation efficiency, and good universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

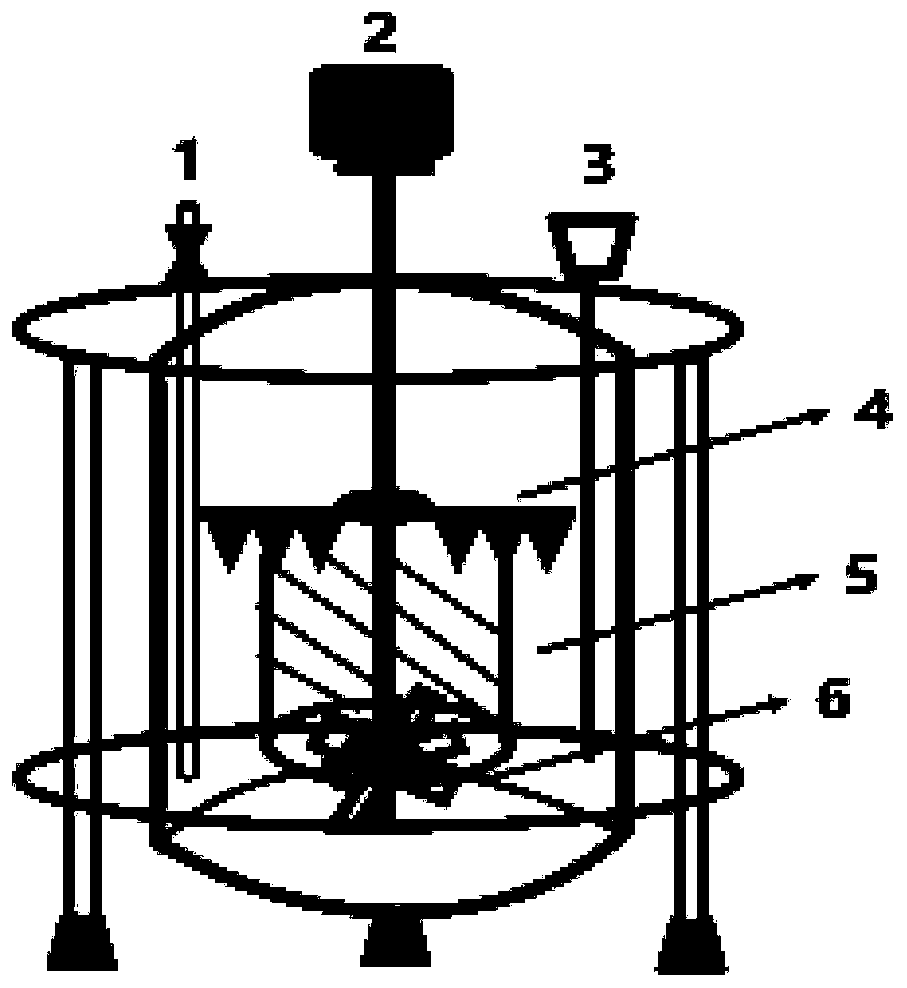

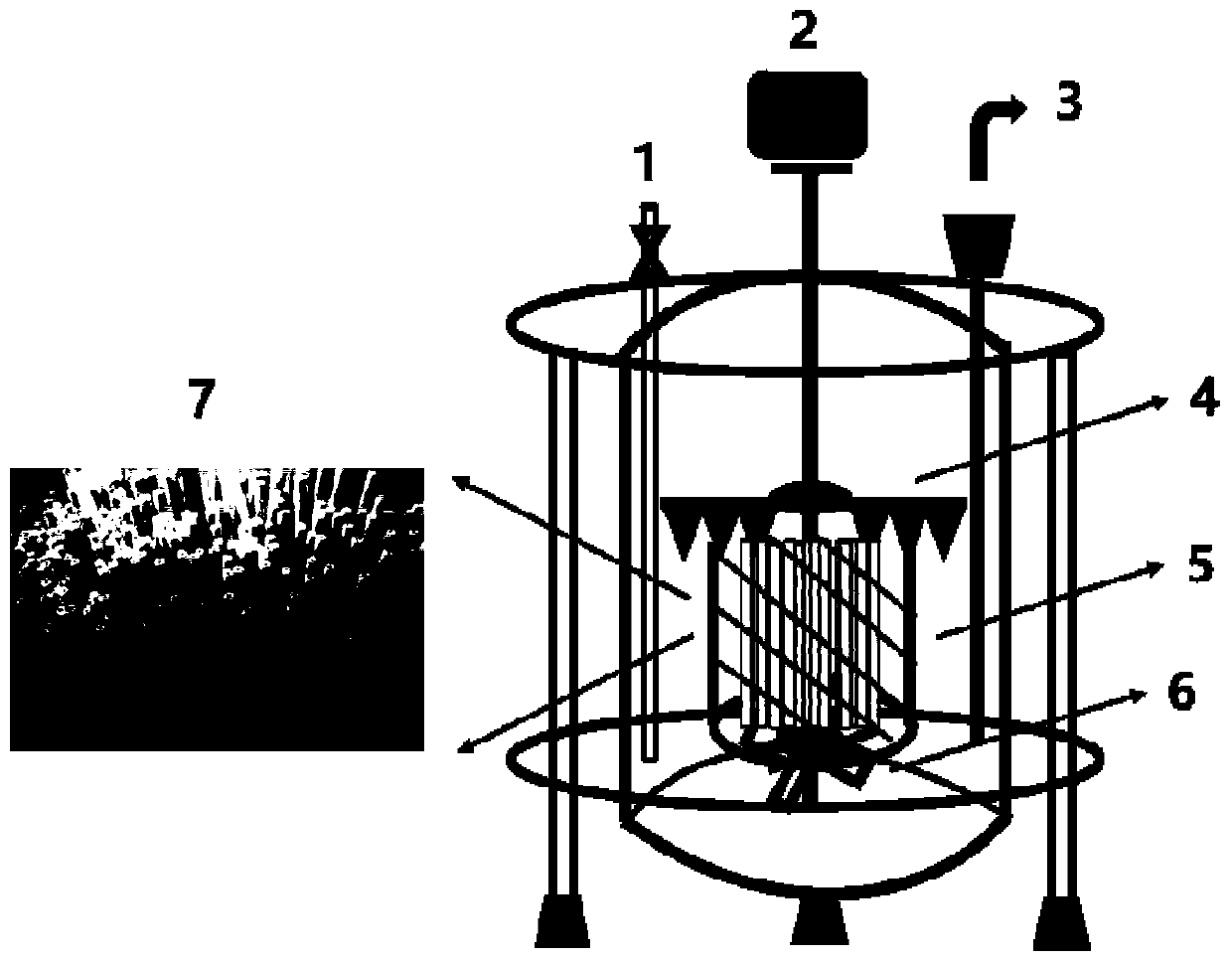

[0028] Example 1 Microbial Universal Immobilization Fermentation Device

[0029] Such as figure 1 As shown, the fermentation device includes a fermenter body, and also includes a sampling port 1, a motor 2, a pH detection port 3, a defoamer 4, a metal frame 5, and a stirring device 6. The metal frame and the stirring device are combined together, and the metal The frame is made of stainless steel, the device is cylindrical, and the top is hollowed out. The materials required for immobilization and fermentation can be placed in the middle. The surrounding is a network structure, which can meet the full contact of the material with the medium. The size of the bottom hole is the stirring shaft of the fermentation tank. diameter, the upper and lower ends of the metal frame are respectively fixed by the stirring shaft and the defoamer.

Embodiment 2

[0031] The fermentation tank is detachably connected by the fermentation tank body and the metal frame, and the metal frame and the stirring device are combined together. When in use, the required base material for immobilized cells can be put into the metal frame, and the loading amount of the material is moderate, and it is best not to exceed the metal frame.

[0032] The immobilization material can be an inorganic material or an organic polymer material. The inorganic material includes but not limited to ceramics, silicon dioxide, alumina; the organic polymer material includes but not limited to polypropylene, polyethylene, polyethersulfone , polyvinylidene fluoride, etc.) flat sheet membrane, hollow fiber membrane, non-woven membrane, nanofiber membrane material; organic polymer material has the characteristics of good anti-microbial decomposition performance, high mechanical strength, stable chemical performance, etc., the following examples, select Polyvinylidene fluorid...

Embodiment 3

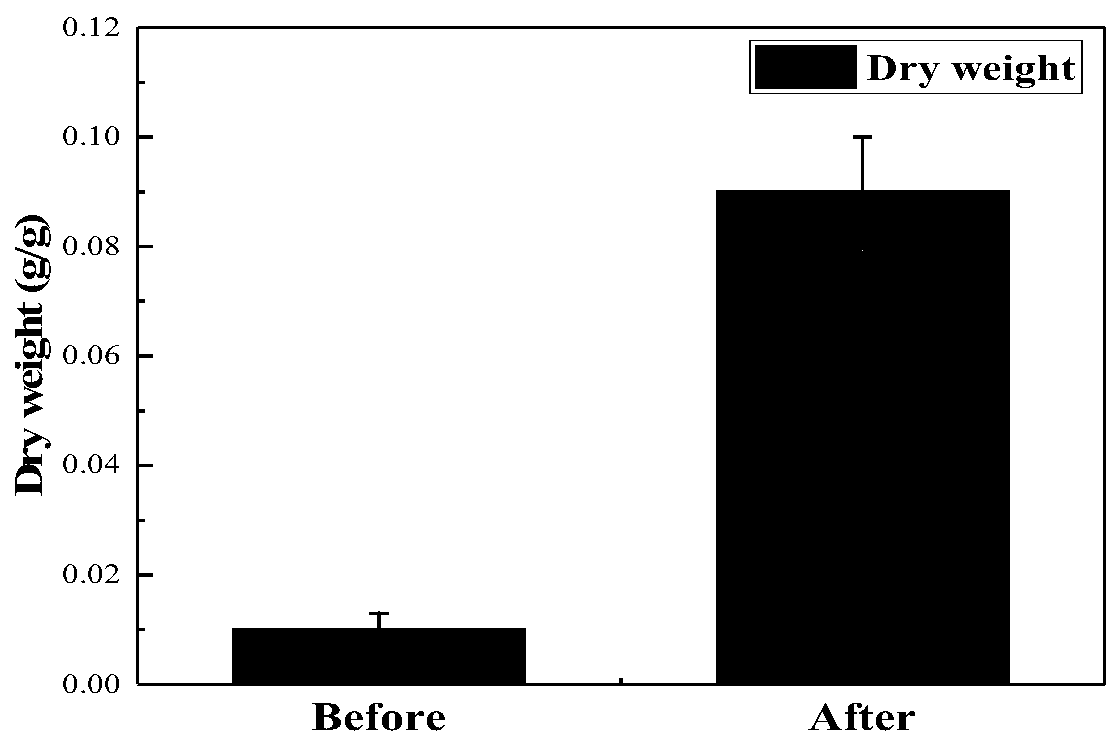

[0033] Example 3 Fermentation using polyvinylidene fluoride hollow fiber membrane as immobilized material

[0034] The unmodified / modified polyvinylidene fluoride hollow fiber membranes were put into metal frames respectively, and fermented in shake flasks. Before and after fermentation, they were washed with pure water and then dried in a freeze dryer for 6 hours, and their weights were measured. The results showed that the dry weight ratio of the modified polyvinylidene fluoride hollow fiber membrane was 8.5 times that of the unmodified one, which indicated that the modified polyvinylidene fluoride hollow fiber membrane was beneficial to the adsorption of bacteria.

[0035] For the modification method of modified polyvinylidene fluoride hollow fiber membrane, see patent CN 109847603 A, which adopts the surface coating modification technology mediated by biosurfactant, and the single factor experiment determines the best modification condition: at a temperature of 25 ℃, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com