Anti-microbial nano protein fiber and preparing method thereof

A technology of protein fiber and zein, applied in the direction of fiber chemical characteristics, single-component protein rayon, dry spinning method, etc., can solve the problems of poor durability, poor dispersion, easy aggregation of antibacterial agents, etc., and achieve long-term antibacterial effect , Improve dispersibility, good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

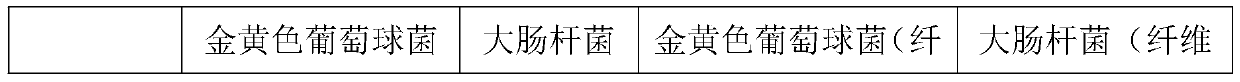

Examples

Embodiment 1

[0016] A preparation method of antibacterial nano protein fiber, comprising the following steps,

[0017] (1) Add zein into 75% aqueous ethanol solution, stir and mix evenly at 200r / min;

[0018] (2) adding the silk protein into the formic acid solution, stirring and mixing evenly;

[0019] (3) Under stirring, add the solution obtained in step (2) to the solution in step (1) and mix evenly, then add silane coupling agent KH560, and stir for 9 hours under acidic conditions;

[0020] (4) Add nano-scale titanium dioxide, ultrasonically disperse evenly, then heat, reflux for 2 hours, and add zinc sulfide;

[0021] (5) The obtained spinning solution is supplied into the syringe through the metering pump, and the spinning solution is extruded through the spinneret through the syringe pump, and the fine flow of the spinning solution is stretched by using high-pressure gas, and collected on the collecting plate to obtain Nanofibers.

[0022] Spinning process parameters: the carrier...

Embodiment 2

[0026] A preparation method of antibacterial nano protein fiber, comprising the following steps,

[0027] (1) Add zein into 75% aqueous ethanol solution, stir and mix evenly at 300r / min;

[0028] (2) adding the silk protein into the formic acid solution, stirring and mixing evenly;

[0029] (3) Under stirring, add the solution obtained in step (2) to the solution in step (1) and mix evenly, then add silane coupling agent KH560, and stir for 10 hours under acidic conditions;

[0030] (4) Add nano-scale titanium dioxide, ultrasonically disperse evenly, then heat, reflux for 2.5 hours, and add zinc sulfide;

[0031] (5) The obtained spinning solution is supplied into the syringe through the metering pump, and the spinning solution is extruded through the spinneret through the syringe pump, and the fine flow of the spinning solution is stretched by using high-pressure gas, and collected on the collecting plate to obtain Nanofibers.

[0032] Spinning process parameters: the carr...

Embodiment 3

[0036] A preparation method of antibacterial nano protein fiber, comprising the following steps,

[0037] (1) Add zein into 75% aqueous ethanol solution, stir and mix evenly at 250r / min;

[0038] (2) adding the silk protein into the formic acid solution, stirring and mixing evenly;

[0039] (3) Under stirring, add the solution obtained in step (2) to step (1) and mix evenly, then add silane coupling agent KH560, and stir and react for 11 hours under acidic conditions;

[0040] (4) Add nano-scale titanium dioxide, ultrasonically disperse evenly, then heat, reflux for 4 hours, and then add zinc sulfide;

[0041] (5) The obtained spinning solution is supplied into the syringe through the metering pump, and the spinning solution is extruded through the spinneret through the syringe pump, and the fine flow of the spinning solution is stretched by using high-pressure gas, and collected on the collecting plate to obtain Nanofibers.

[0042] Spinning process parameters: the carrier...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com