LED chip capable of improving external quantum efficiency, and preparation method thereof

An LED chip and external quantum efficiency technology are applied in the field of LED chips and their preparation for improving external quantum efficiency, so as to achieve the effects of improving external quantum efficiency, improving luminous efficiency and simple process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

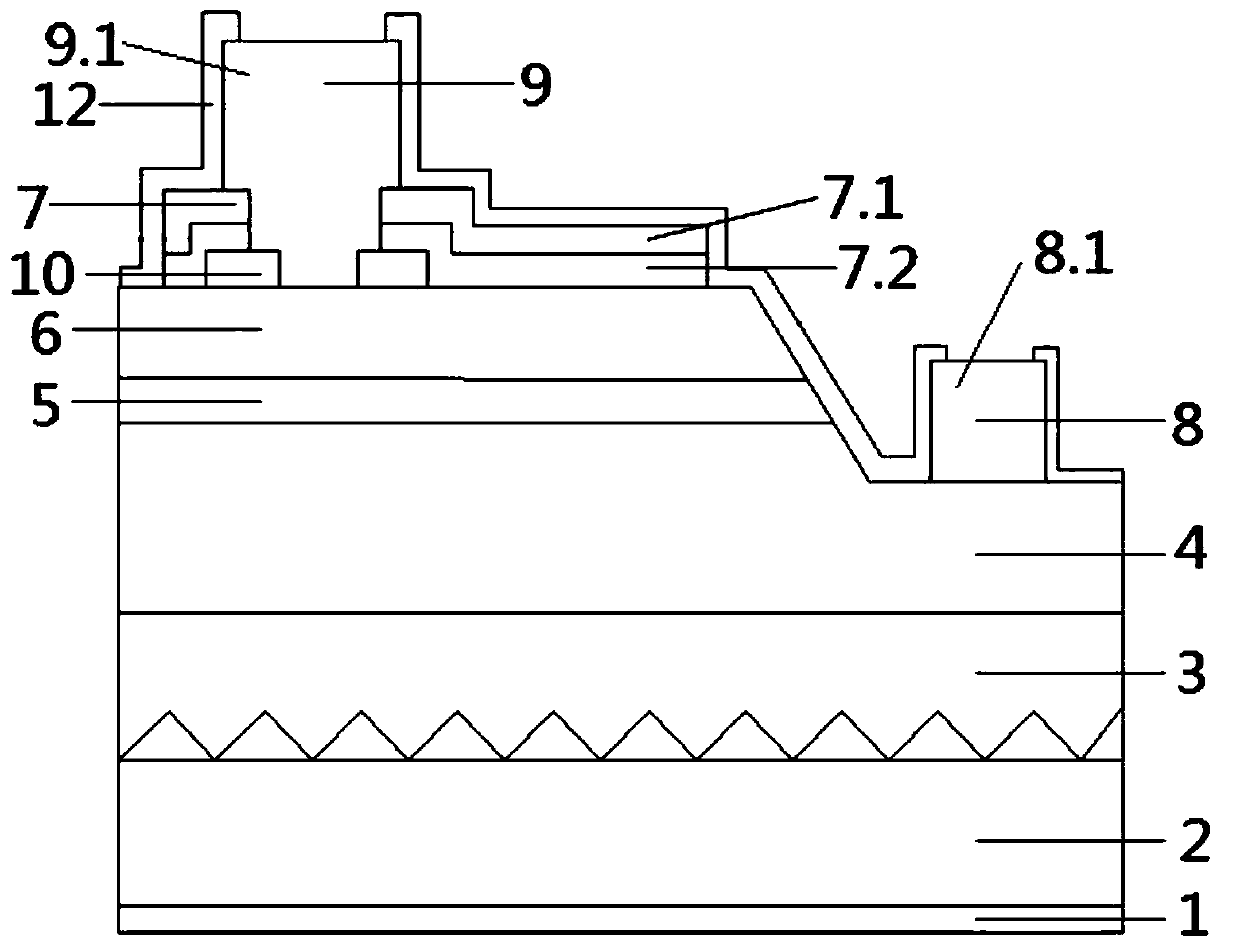

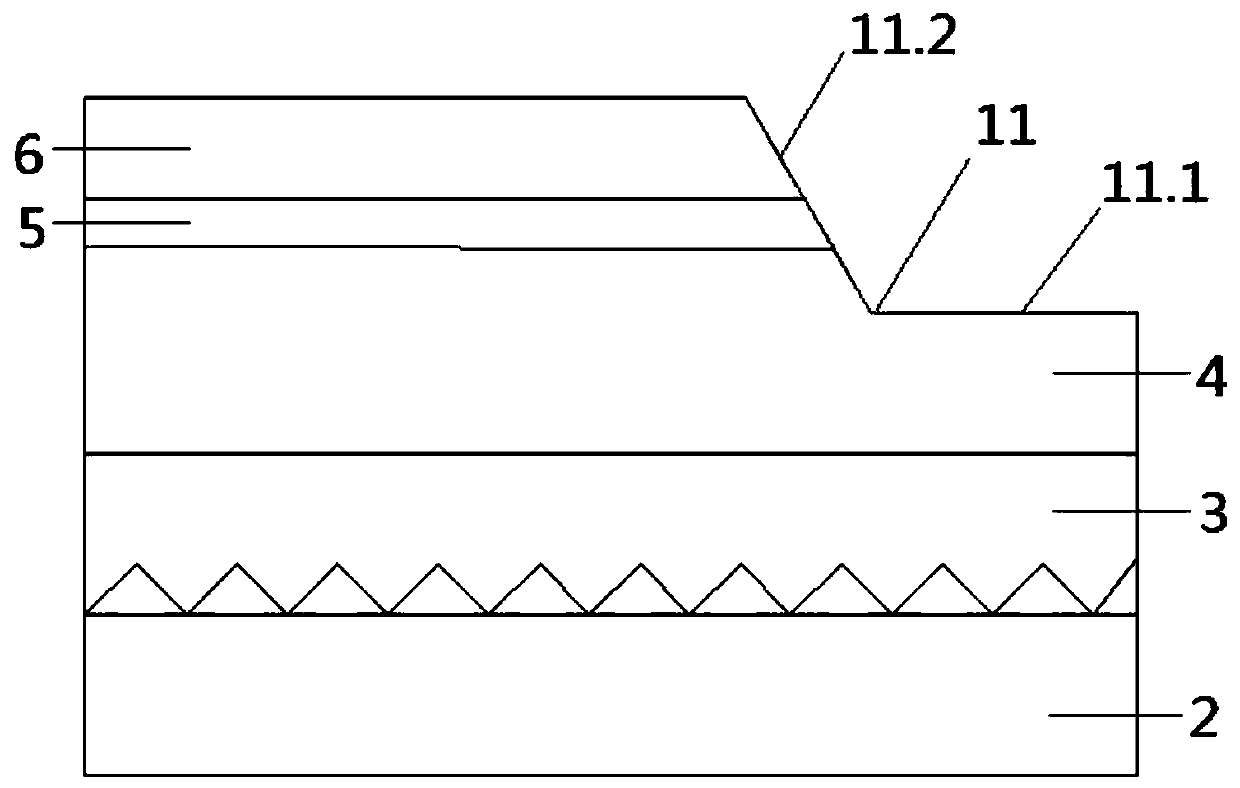

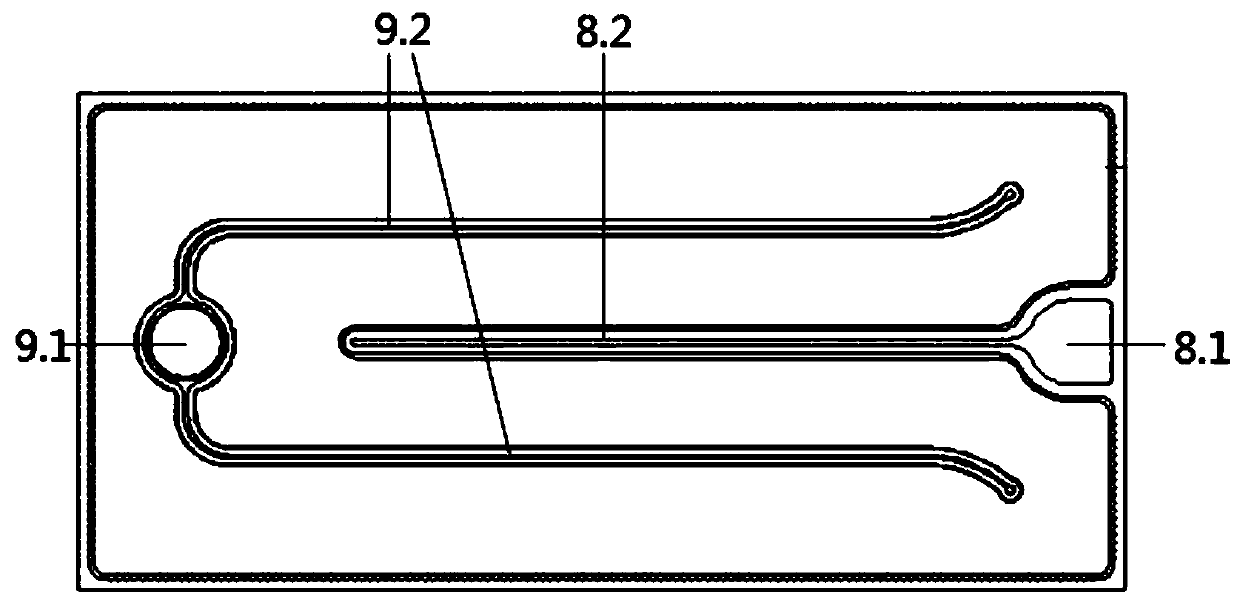

[0053] See Figure 1 to Figure 11 , An LED chip with improved external quantum efficiency and a preparation method thereof, this embodiment is applied to improve the external quantum efficiency of the LED chip.

[0054] An LED chip with improved external quantum efficiency, see figure 1 , Including from bottom to top:

[0055] DBR layer 1. In this embodiment, the DBR material is silicon dioxide (SiO 2 ) And titanium dioxide (TiO 2 ) Alternate structure, the refractive indices of the two materials are between 1.45~1.52 and 2.45~2.55, and the thickness of each layer is determined by optical software simulation to form a distributed Bragg reflector (DBR) whose reflectivity is in the visible wavelength range ( 380~800nm) greater than 95%;

[0056] The substrate 2 located on the DBR layer 1. In this embodiment, the substrate 2 is a sapphire substrate (PSS substrate);

[0057] A buffer layer 3 on the substrate 2;

[0058] The first semiconductor layer 4 located on the buffer layer 3. In thi...

Embodiment 2

[0086] The difference between Example 2 and Example 1 is that the selected electron beam evaporation zinc oxide deposition temperature is 250°C, and the others are the same as Example 1. Under this combination of process parameters, the obtained AZO layer 7.1 has uniform crystal grains and crystal grain size Between 30nm and 50nm, the thrust experiment meets the requirements, and the brightness of the LED chip is improved.

Embodiment 3

[0088] The difference between Example 3 and Example 1 is that the selected electron beam evaporation zinc oxide deposition temperature is 300°C, and the rotation speed of the plating pot is 60r / min. Others are the same as Example 1. Under this combination of process parameters, the AZO layer obtained 7.1 The crystal grain is uniform, and the crystal grain size is between 30nm and 50nm. After the electrode is plated, the pad shows a slight black spot, which affects the appearance, but does not affect the bonding wire. The thrust experiment meets the requirements, and the brightness of the LED chip is improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com