Graphene-based conductive pigment and preparation method thereof

A conductive pigment and graphene-based technology, applied in the field of pigment manufacturing, can solve problems such as poor dispersion, poor stability and storage performance of conductive pigments, and influence on the development of conductive pigments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

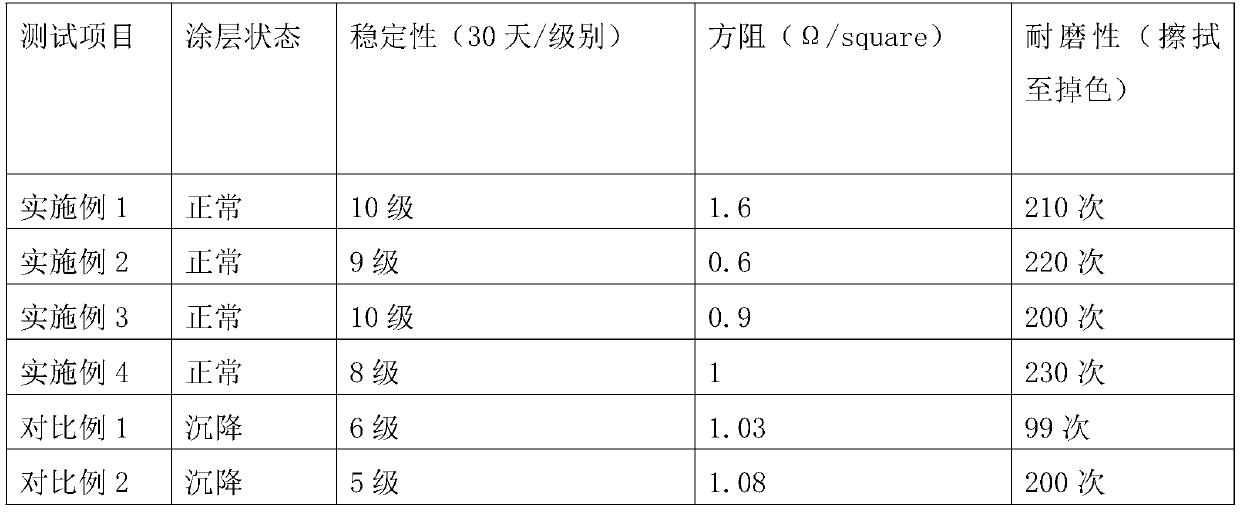

Examples

Embodiment 1

[0020] The graphene-based conductive pigment includes the following components by weight: 5-25 parts of graphene oxide solution, 40-50 parts of matrix resin, 3-6 parts of additives, 4-5 parts of pigment, 10-20 parts of calcium sulfate, 5-15 parts of zinc phosphate.

[0021] The mass percentage of graphene oxide in the graphene oxide solution is 1-10%, the solvent is water or an organic solvent, and the organic solvent is at least one of methanol, ethanol, propanol, isopropanol, acetone, methyl ethyl ketone, and ethylene glycol. A sort of.

[0022] The matrix resin includes one or more of polyester resin, epoxy resin, polyurethane resin and fluorine resin.

[0023] The auxiliary agent includes one or more of cross-linking coupling agent, leveling agent and dispersant.

[0024] The cross-linking coupling agent is a silane coupling agent; the leveling agent is polyether polyester modified organosiloxane; the dispersant is polycarboxylate ammonium salt or sodium salt dispersant....

Embodiment 2

[0028] Disperse 25 kg of graphene oxide in 225 kg of methanol, adjust the pH value to 10 by sodium hydroxide, put 40 kg of epoxy resin, 6 kg of a mixture of silane and polyether polyester modified organosiloxane in equal parts, Heat and stir 4kg of pigment for 12H; add 20kg of calcium sulfate and 5kg of calcium phosphate and heat and stir for 2H to prepare a graphene-based conductive pigment.

Embodiment 3

[0030] Disperse 15kg of graphene oxide in 285kg of propanol, adjust the pH value to 11 by sodium hydroxide, put 45kg of a mixture of polyurethane resin and fluororesin in equal parts, and polyether polyester modified silicone in equal parts in the heating container 5kg of the mixture of oxane and polycarboxylate ammonium salt, 4.5kg of pigments were heated and stirred for 11H; 15kg of calcium sulfate and 10kg of calcium phosphate were added and heated and stirred for 2.5H to prepare graphene-based conductive pigments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com