Low-temperature doped perovskite thin film with high photoluminescence quantum yield and preparation method thereof

A quantum yield, perovskite technology, applied in photovoltaic power generation, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of low solubility, change stability, and high cost of all-inorganic perovskite, and achieve improved The effect of photoluminescence quantum yield, reducing solvent vapor pressure, and accelerating solvent volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] A perovskite film with low-temperature doping and high photoluminescence quantum yield and a preparation method thereof, comprising the following steps:

[0056] (1) Substrate preparation. In the present invention, a glass substrate is used. First, the substrate is cut into a suitable size (2cm×2cm), and then ultrasonically cleaned in an ultrasonic cleaner with deionized water, acetone, isopropanol, and absolute ethanol in sequence. 15min, and then dry it with nitrogen, and treat it for 15min in a UV cleaning ozone machine with a power of 40W to obtain a clean substrate.

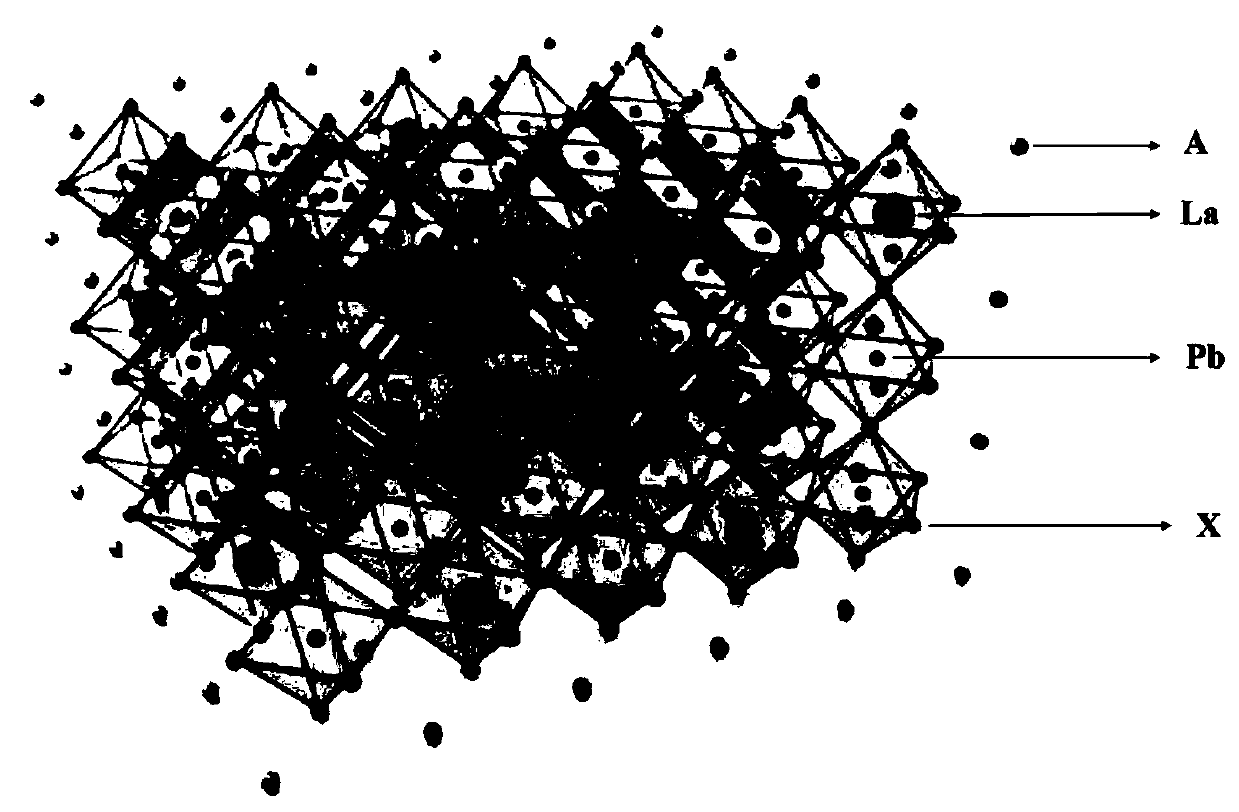

[0057] (2) Prepare the precursor solution. Dissolving the halide salt M, lead halide, and lanthanum halide in the solvent S to obtain a precursor solution; stirring the precursor solution at a constant temperature for reaction, and then aging to obtain a perovskite doped lanthanum precursor solution;

[0058] (3) Film preparation. After filtering the perovskite-doped lanthanum precursor solution, s...

Embodiment 1

[0074] This embodiment provides a method for preparing a green fluorescent perovskite film.

[0075] According to above-mentioned step 1) in mode cleaning glass plate; FABr, CsBr, PbBr 2 , LaBr 3According to the molar ratio of 0.945:0.105:1:0.12, it is dissolved in 1.25ml of mixed solvent of DMSO and DMF with a volume ratio of 9:1, and the above weighing error is controlled within 0.1mg.

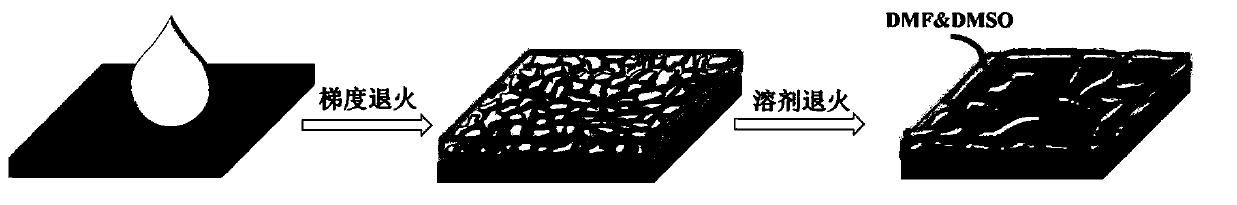

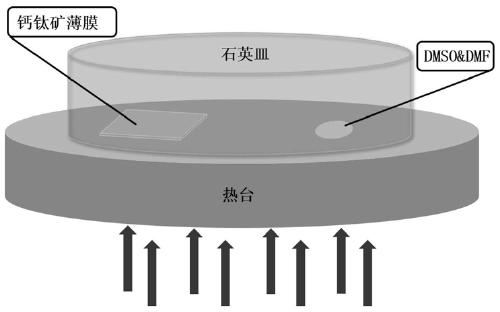

[0076] The perovskite thin film was prepared according to step 3) of the above specific embodiment, wherein the post-annealing temperature was 70°C. figure 2 It is a schematic diagram of gradient annealing and then solvent annealing in the preparation process of perovskite film. Gradient annealing prevents uneven nucleation and film cracks caused by too fast solvent volatilization. Solvent annealing method is used to recombine the crystallized small particle crystals. Growing up is conducive to the improvement of crystal quality. Solvent annealing specific operation see image 3 .

Embodiment 2

[0089] This embodiment provides a method for preparing a red fluorescent perovskite film.

[0090] According to the specific embodiment step 1) mode cleaning glass sheet; Weigh MAI, PbI 2 , DMSO, LaI 3 Add it to 1ml DMF at a molar ratio of 1:1:1:0.1, and the above weighing error should be controlled within 0.1mg. The perovskite thin film is prepared according to the method in step 3) of the above specific embodiment, wherein the post-annealing temperature needs to be set at 100° C., and other conditions remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluorescence quantum yield | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com