A kind of preparation method of environment-friendly inorganic non-metal fire-resistant cable box

An inorganic non-metallic, fire-resistant cable technology, applied in cable installation, cable installation in tunnels, electrical components, etc., can solve the problem of limited fire-proof effect of fire-resistant cable trays, easy oxidation, rust and softening of metal fire-resistant cable trays Deformation and other problems, to achieve the effect of easy continuous installation, good connectability and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

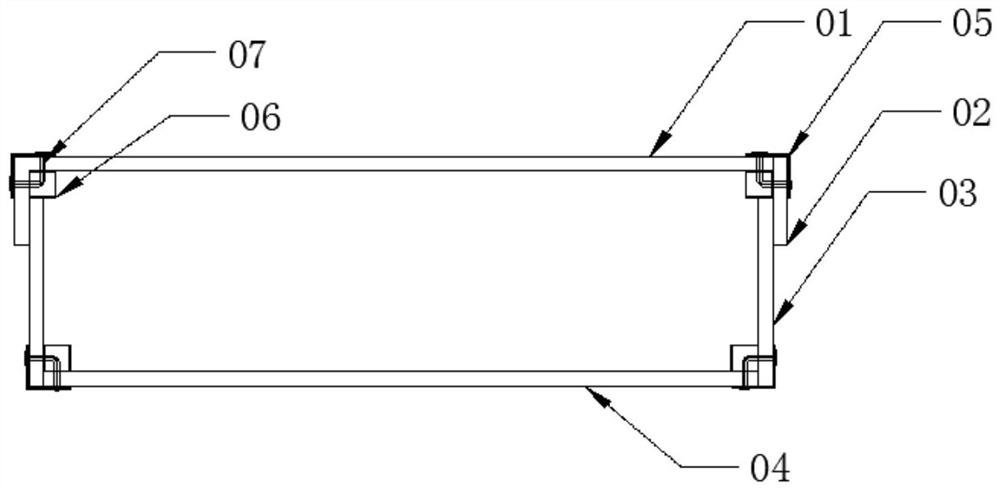

Image

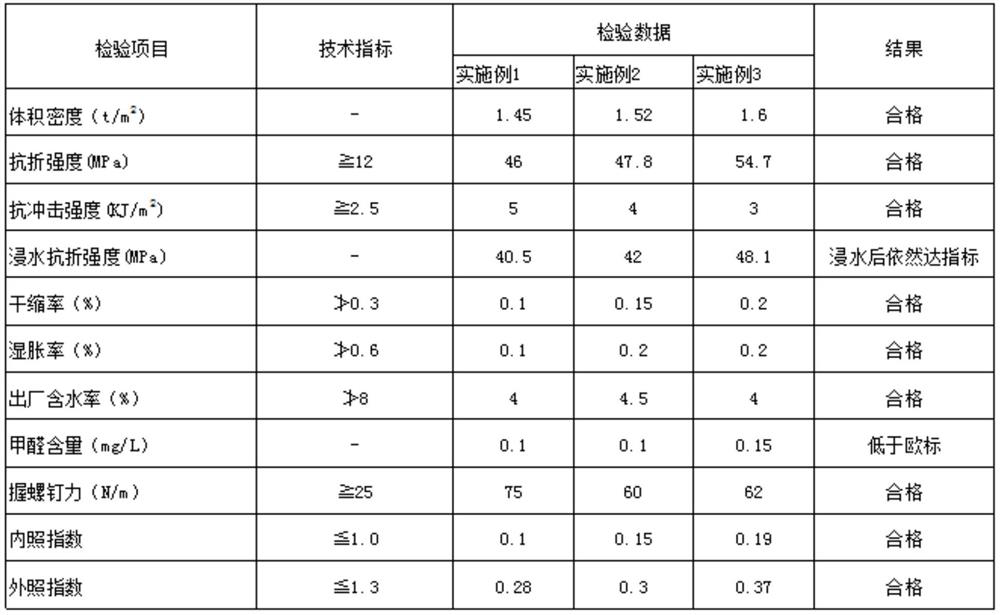

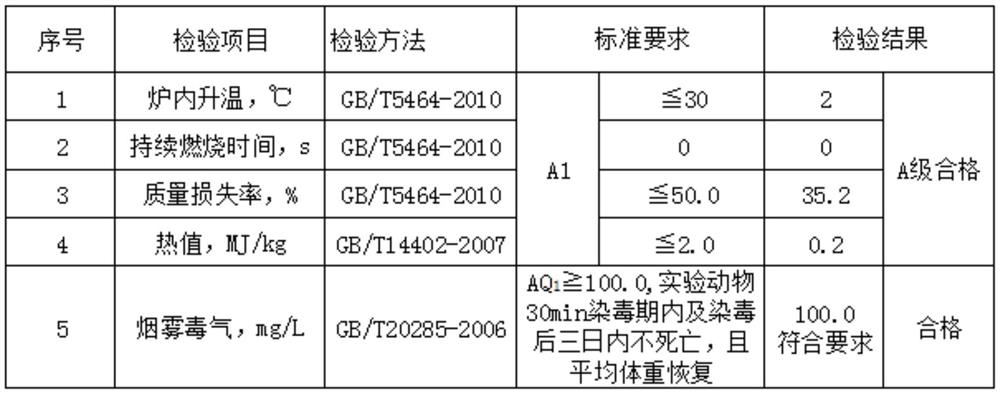

Examples

Embodiment 1

[0029] A preparation method of an inorganic non-metallic fire-resistant cable trough is carried out according to the following steps:

[0030] Step (1): Mix and stir 62 parts of magnesium sulfate and 57 parts of water according to the specific gravity to make a magnesium sulfate solution, put it into a mixer for use, weigh 100 parts of magnesium oxide and 1.5 parts of calcium stearate and add it to the batching bin successively. Transfer to the mixer and stir with the magnesium sulfate solution for 18min;

[0031] Step (2): Add bentonite, fly ash, talcum powder, citric acid monohydrate, sodium citrate, and organic silicon in sequence and continue stirring for 12 minutes to form a slurry. Among the modified additives, 1.2 parts of citric acid monohydrate, sodium citrate 0.7 parts, 0.5 parts of organic silicon, 6 parts of bentonite, 20 parts of fly ash and 22 parts of talcum powder in the filling material;

[0032] Step (3): irradiating the above slurry with Cs-137 for 8 hours;...

Embodiment 2

[0039] A preparation method of an inorganic non-metallic fire-resistant cable trough is carried out according to the following steps:

[0040] Step (1): Mix and stir 60 parts of magnesium sulfate and 60 parts of water according to the specific gravity to make a magnesium sulfate solution, put it into a mixer for use, weigh 100 parts of magnesium oxide and 2.8 parts of calcium stearate and add it to the batching bin successively. Transfer to the mixer and stir with the magnesium sulfate solution for 15 minutes;

[0041] Step (2): Add bentonite, fly ash, talcum powder, citric acid monohydrate, sodium citrate, and organic silicon in sequence and continue stirring for 10 minutes to form a slurry. Among the modification additives, 0.8 parts of citric acid monohydrate, sodium citrate 1 part, 0.2 parts of silicone, 10 parts of bentonite, 12 parts of fly ash, and 28 parts of talcum powder in the filling material;

[0042] Step (3): irradiating the above slurry with Cs-137 for 7 hours...

Embodiment 3

[0047] A preparation method of an inorganic non-metallic fire-resistant cable trough is carried out according to the following steps:

[0048] Step (1): Mix and stir 65 parts of magnesium sulfate and 55 parts of water according to the specific gravity to make a magnesium sulfate solution, put it into a blender for use, weigh 100 parts of magnesium oxide and 0.5 part of calcium stearate and add it to the batching bin successively. Transfer to the mixer and stir with magnesium sulfate solution for 20min;

[0049] Step (2): Add bentonite, fly ash, talcum powder, citric acid monohydrate, sodium citrate, and organic silicon in sequence and continue stirring for 15 minutes to form a slurry. Among the modified additives, 1.6 parts of citric acid monohydrate, sodium citrate 0.5 parts, 1 part of silicone, 5 parts of bentonite, 28 parts of fly ash, and 18 parts of talcum powder in the filling material;

[0050] Step (3): irradiating the above slurry with Cs-137 for 6 hours;

[0051] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com