Method for preparing glycyrrhetinic acid monoglucuronide by liquorice fermentation

A technology of glycyrrhetinic acid aldehyde and licorice aldehyde, which is applied in the field of microbial engineering, can solve problems such as affecting the consumption of GL by microorganisms, difficulty in product separation, and high price, and achieves suitable for large-scale production, simple operating parameters, and low production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1. A method for preparing glycyrrhetinic acid monoglucuronate by fermentation of licorice, comprising the following steps:

[0037] 1) Preparation of seed culture solution: Weigh 200g of potatoes, wash, peel and cut into small pieces, add water and boil for 20-30 minutes, filter with eight layers of gauze, add 20g of glucose, stir and mix well, and then make up water to 1000mL after cooling for a while , divided into Erlenmeyer flasks, stoppered and bandaged, sterilized at 121°C for 25 minutes, and then inserted into a plant endophytic fungus Chaetomium globosum DX-THS3 screened by our research team after cooling down, cultured at 28°C and 180rpm on a shaking table for 72h. Get the seed solution.

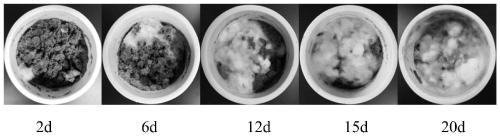

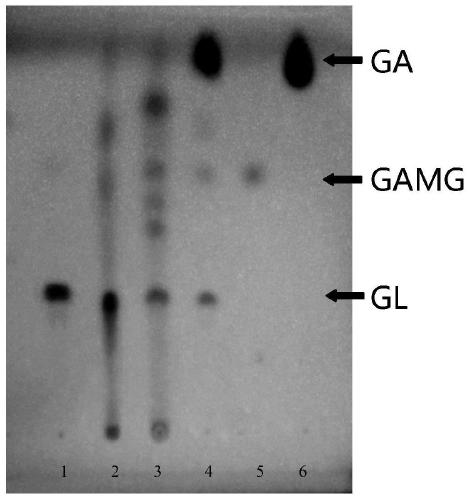

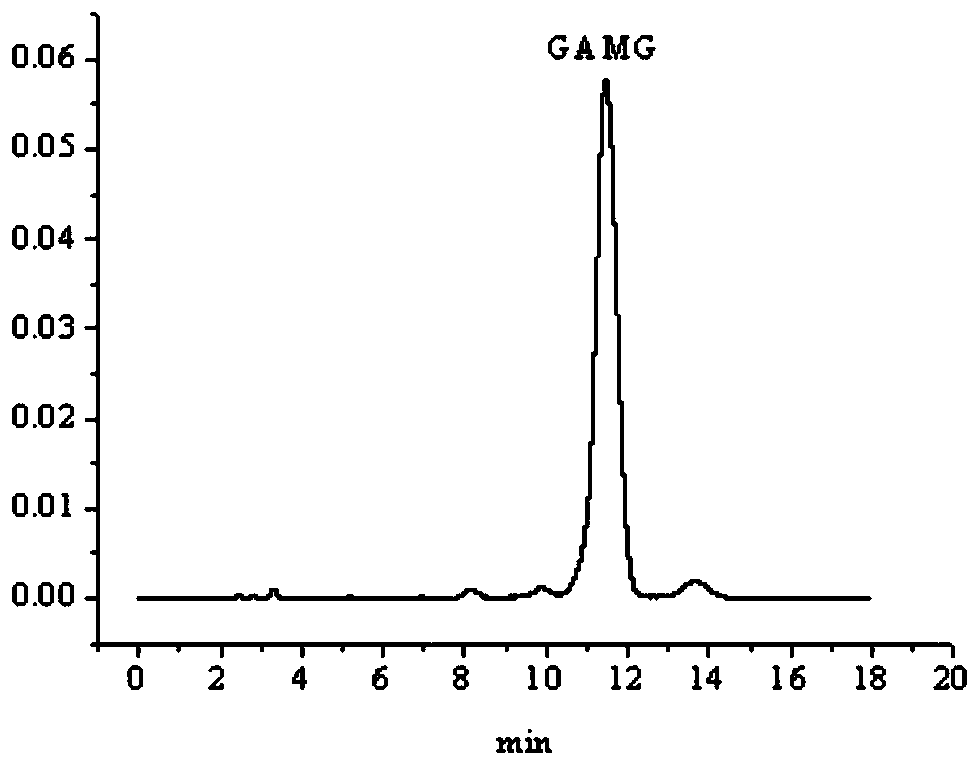

[0038] 2) Solid-state fermentation: dry licorice, crush it to 10 mesh, take 15g into a 250mL Erlenmeyer flask, mix it with 2g of wheat bran, add 50mL of culture medium (containing glucose 10g / L; ammonium nitrate 3g / L; KH 2 PO 4 2.2g / L; NaCl 0.5g / L; Magnesium Sul...

Embodiment 2

[0041] Embodiment 2, a method for preparing glycyrrhetinic acid monoglucuronate by fermentation of licorice, comprising the following steps:

[0042] 1) Preparation of seed culture solution: Weigh 200g of potatoes, wash, peel and cut into small pieces, add water and boil for 20-30 minutes, filter with eight layers of gauze, add 20g of glucose, stir and mix well, and then make up water to 1000mL after cooling for a while , divided into Erlenmeyer flasks, stoppered and bandaged, sterilized at 121°C for 25 minutes, and then inserted into a plant endophytic fungus Chaetomium globosum DX-THS3 screened by our research team after cooling down, cultured at 28°C and 180rpm on a shaking table for 72h. Get the seed solution.

[0043] 2) Solid-state fermentation: dry licorice, crush it to 10 mesh, take 15g into a 250mL triangular flask, mix with 2g of rice husk, add 50mL of culture medium (containing 10g / L of sucrose; 3g / L of peptone; KH 2 PO 4 2.2g / L; NaCl 0.5g / L; Magnesium Sulfate 0....

Embodiment 3

[0046] Embodiment 3, a method for preparing glycyrrhetinic acid monoglucuronate by fermentation of licorice, comprising the following steps:

[0047] 1) Preparation of seed culture solution: Weigh 200g of potatoes, wash, peel and cut into small pieces, add water and boil for 20-30 minutes, filter with eight layers of gauze, add 20g of glucose, stir and mix well, and then make up water to 1000mL after cooling for a while , divided into Erlenmeyer flasks, stoppered and bandaged, sterilized at 121°C for 25 minutes, and then inserted into a plant endophytic fungus Chaetomium globosum DX-THS3 screened by our research team after cooling down, cultured at 28°C and 180rpm on a shaking table for 72h. Get the seed liquid.

[0048] 2) Solid-state fermentation: dry licorice, crush it to 10 mesh, take 15g into a 250mL triangular flask, mix it with 2g of corn cob, add 50mL of culture medium (which contains fructose 10g / L; yeast powder 3g / L; KH 2 PO 4 2.2g / L; NaCl 0.5g / L; Magnesium Sulfat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com