Full-flexible pyroelectric infrared detector

A pyroelectric infrared detector technology, which is applied to electrical radiation detectors, instruments, measuring devices, etc., can solve the problems of inflexibility, difficult integration of infrared detectors, and reduced application prospects of pyroelectric infrared detectors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

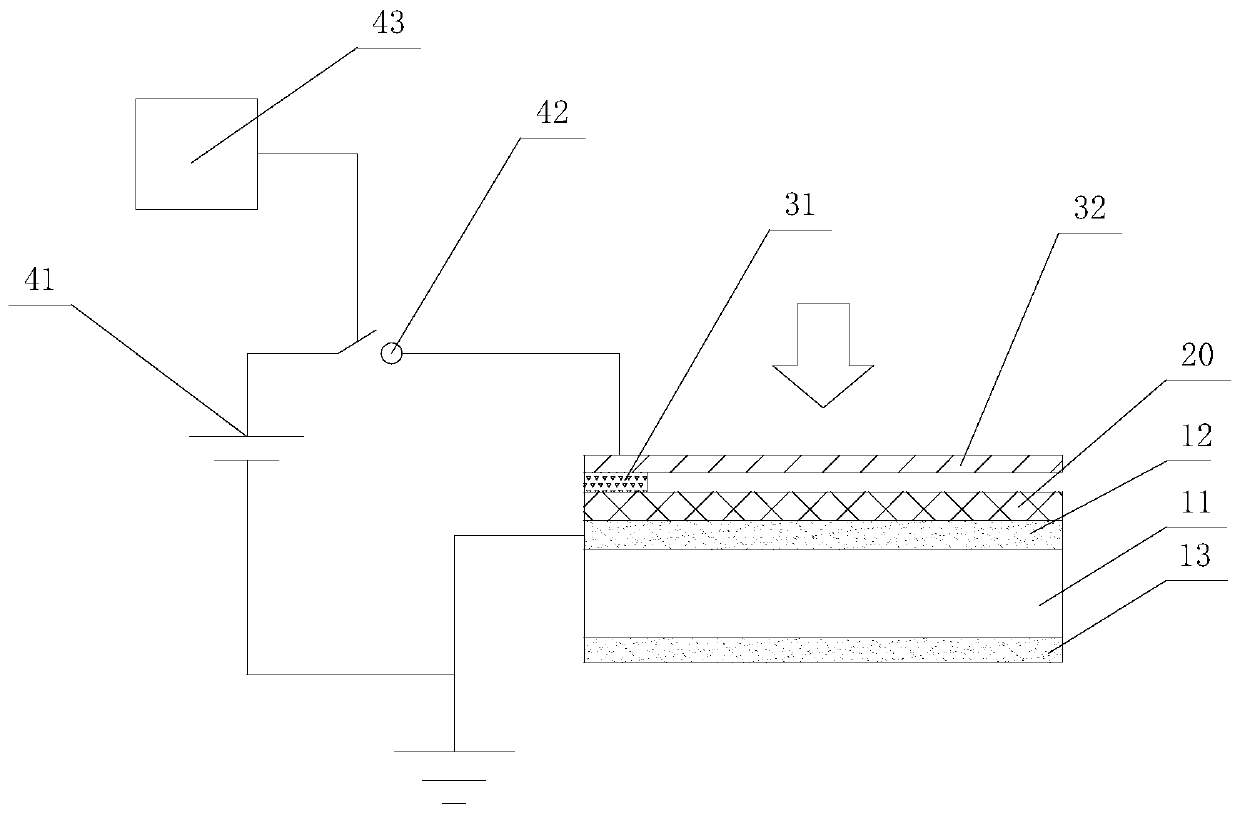

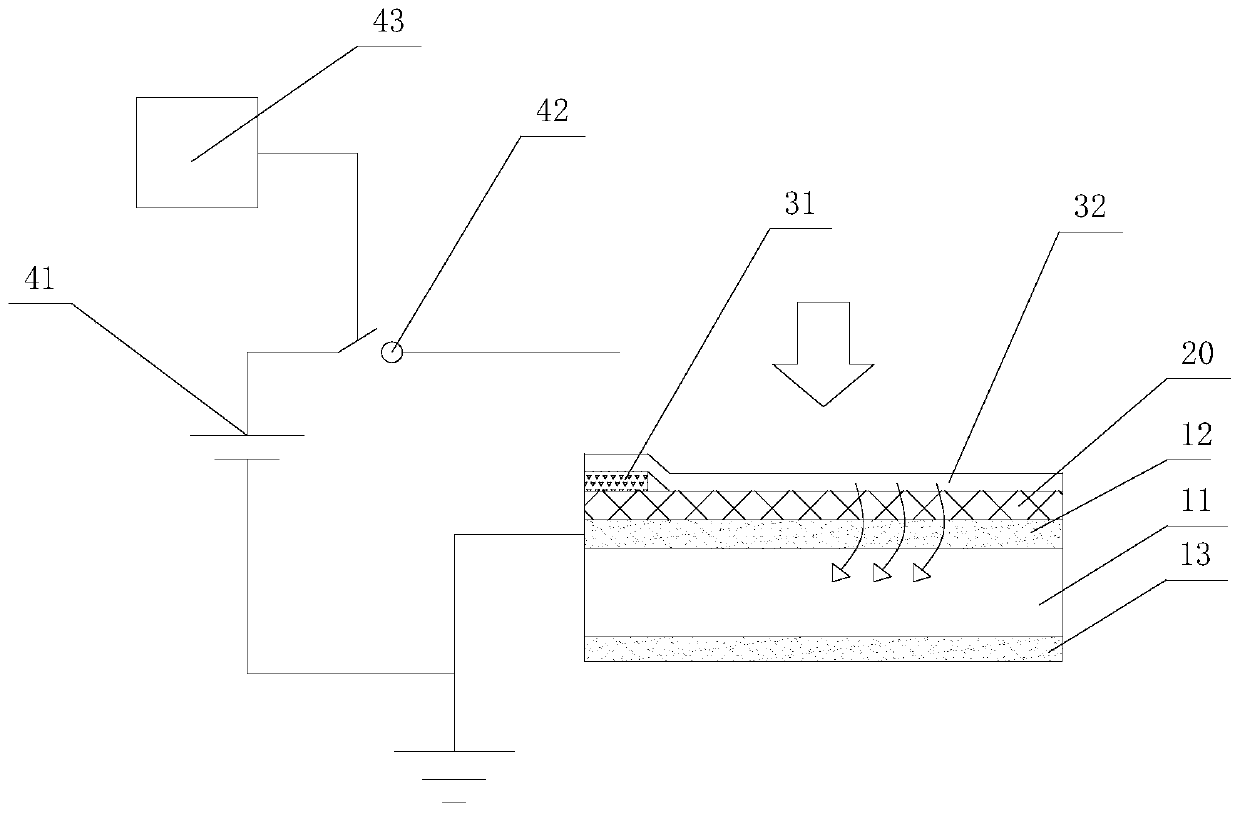

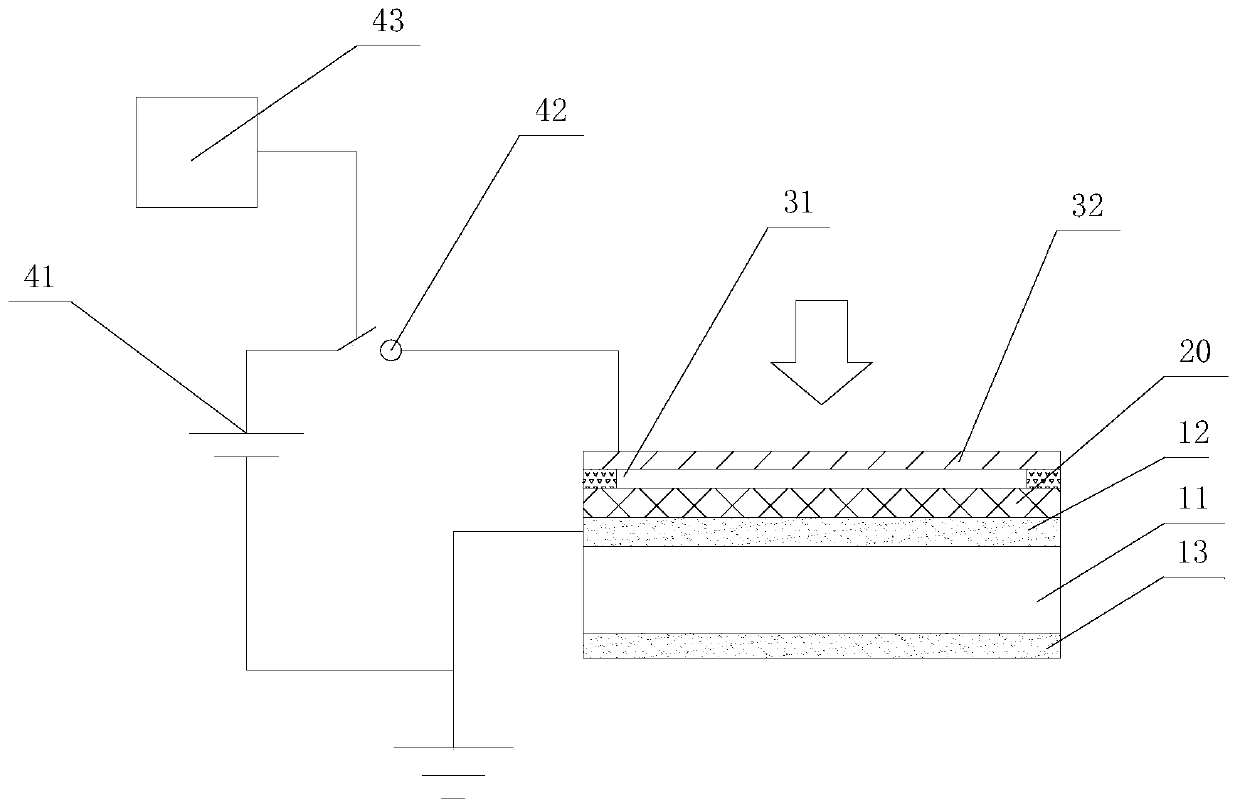

[0035] Such as Figure 1~4 As shown, a fully flexible pyroelectric infrared detector provided in this embodiment includes a flexible infrared radiation modulation mechanism and a flexible infrared pyroelectric sensitive unit, and the flexible infrared pyroelectric sensitive unit includes sequentially arranged from top to bottom The insulating layer 20, the upper electrode layer 12, the pyroelectric sensitive film 11 and the lower electrode layer 13; the flexible infrared radiation modulation mechanism is installed on the insulating layer 20, and the flexible infrared radiation modulation mechanism includes 1 or 2 The support column 31 and the metal film 32, the metal film 32 is installed on the support column 31 to form a single-ended or double-ended cantilever beam; the metal film 32 of the cantilever beam and the upper electrode of the flexible infrared pyroelectric sensitive unit pass through the circuit switch 42 A voltage source 41 is connected, and the circuit switch 42 ...

Embodiment 2

[0043] Such as Figure 5 As shown, a method for manufacturing a fully flexible pyroelectric infrared detector provided in this embodiment includes the following steps:

[0044] Step 1: Sputtering a nickel-chromium alloy thin film with a thickness of 1 μm on the base 51 prepared from a silicon wafer as the sacrificial layer 52 .

[0045] Step 2: The flexible pyroelectric polymer is completely dissolved into a solution, and then the solution is evenly covered on the sacrificial layer 52 of the base 51, and then placed in a constant temperature oven and baked until the solvent is completely volatilized, and the flexible pyroelectric polymer is formed Pyroelectric sensitive film 11.

[0046] Step 3: On the upper surface of the pyroelectric sensitive film 11, 100 nm of metal aluminum is prepared by sputtering as the upper electrode layer 12 of the flexible infrared pyroelectric sensitive unit.

[0047] Step 4: Prepare a 200 nm silicon nitride dielectric thin film as the insulatin...

Embodiment 3

[0055] Such as Figure 4 As shown, this embodiment provides a method for manufacturing a fully flexible pyroelectric infrared detector, comprising the following steps:

[0056] Step 1: Sputtering a nickel-chromium alloy thin film with a thickness of 1 μm on the base 51 prepared from a silicon wafer as the sacrificial layer 52 .

[0057] Step 2: The flexible pyroelectric polymer is completely dissolved into a solution, and then the solution is evenly covered on the sacrificial layer 52 of the base 51, and then placed in a constant temperature oven and baked until the solvent is completely volatilized, and the flexible pyroelectric polymer is formed Pyroelectric sensitive film 11.

[0058] Step 3: On the upper surface of the pyroelectric sensitive film 11, 100 nm of metal aluminum is prepared by sputtering as the upper electrode layer 12 of the flexible infrared pyroelectric sensitive unit.

[0059] Step 4: Prepare a 200 nm silicon nitride dielectric thin film as the insulatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com