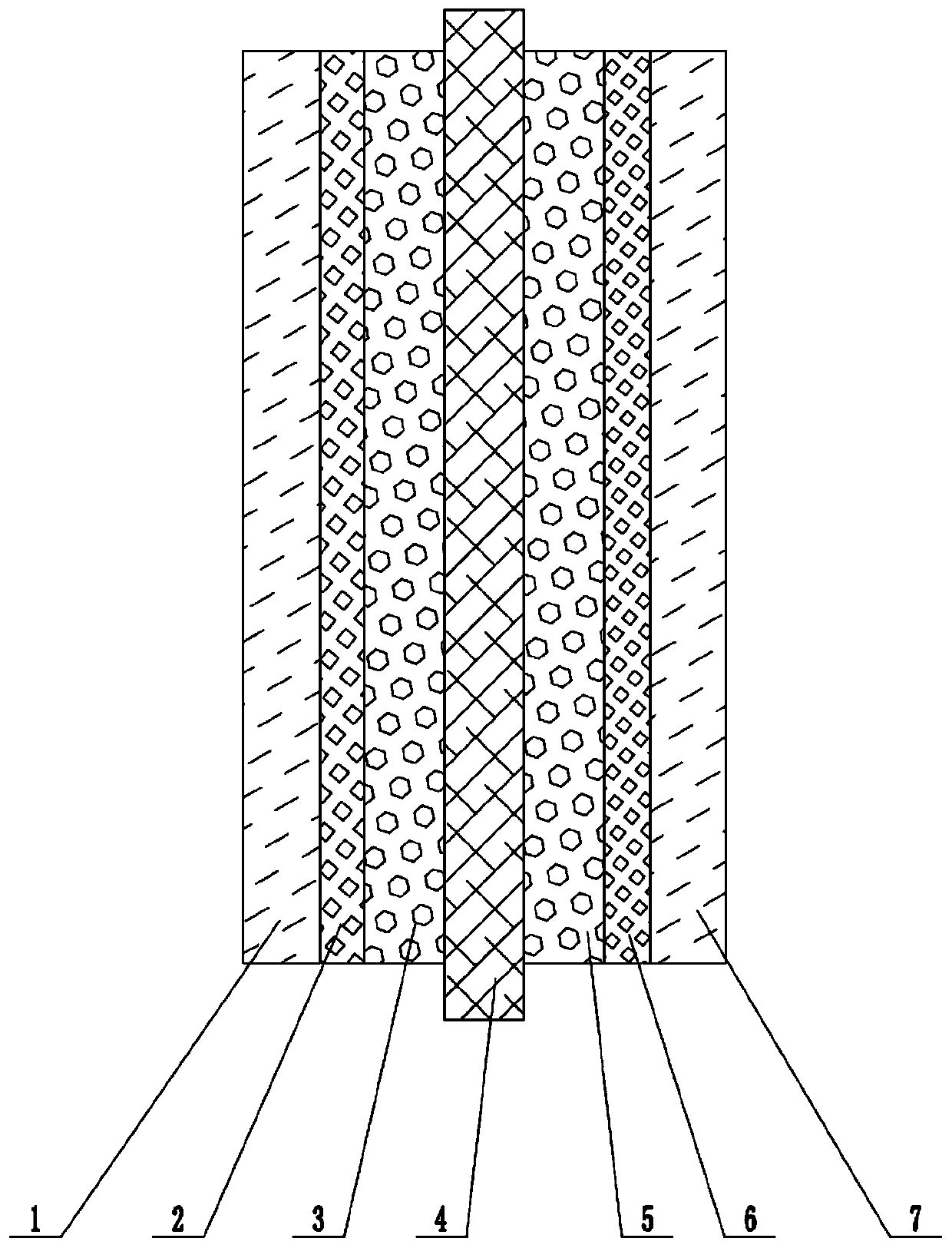

Medium-temperature proton exchange membrane fuel cell membrane electrode and preparation method thereof

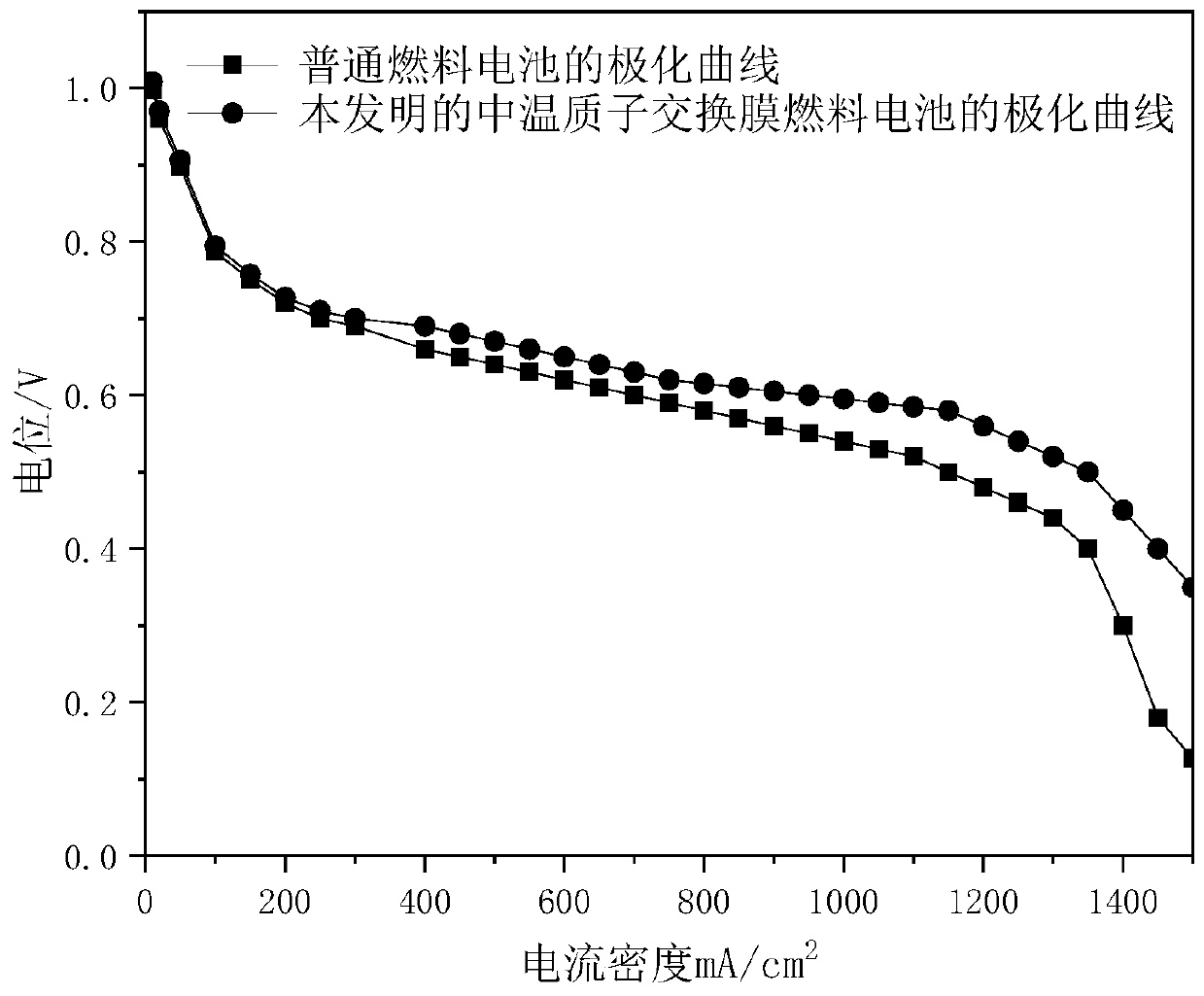

A proton exchange membrane and fuel cell membrane technology, applied in fuel cells, battery electrodes, circuits, etc., can solve the problems of high fuel cell cost, battery performance degradation, severe swelling, etc., achieve high-power discharge performance, improve conductivity , reduce the effect of moisture volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation method of the membrane electrode of the medium temperature proton exchange membrane fuel cell specifically comprises the following steps:

[0044] (1) Hydrophobic treatment of the base layer

[0045] At room temperature, carbon paper was used as the base layer, and the base layer material was ultrasonically cleaned in deionized water for 30 minutes, then taken out and soaked in acetone solution for 12 hours, and then cleaned with deionized water and absolute ethanol in sequence. Put it in an oven at 60°C to dry for 0.5h, weigh it, put the base layer material into 2wt% hydrophobic agent and soak it for 5min, then take it out and put it in the oven to dry for 0.5h, repeat the soaking-drying process several times , until the content of the hydrophobic agent in the base layer reaches 15%, and finally put the base layer in a muffle furnace and heat it up to 240°C for 0.5h, and then heat up to 340°C for 0.5h to melt the PTFE and adhere to the surface of the ba...

Embodiment 2

[0056] The preparation method of the membrane electrode of the medium temperature proton exchange membrane fuel cell specifically comprises the following steps:

[0057] (1) Hydrophobic treatment of the base layer

[0058] At room temperature, carbon paper was used as the base layer, and the base layer material was ultrasonically cleaned in deionized water for 30 minutes, then taken out and soaked in acetone solution for 12 hours, and then cleaned with deionized water and absolute ethanol in sequence. Put it in an oven at 80°C to dry for 0.5h, weigh it, put the material of the base layer into 2wt% hydrophobic agent and soak it for 5min, then take it out and dry it in the oven for 0.5h, repeat the soaking-drying process several times , until the content of the hydrophobic agent in the base layer reaches 18%, and finally put the base layer in a muffle furnace and raise the temperature to 245°C for 0.5h heat treatment, then raise the temperature to 345°C and continue roasting for...

Embodiment 3

[0069] The preparation method of the membrane electrode of the medium temperature proton exchange membrane fuel cell specifically comprises the following steps:

[0070] (1) Hydrophobic treatment of the base layer

[0071] At room temperature, carbon paper was used as the base layer, and the base layer material was ultrasonically cleaned in deionized water for 30 minutes, then taken out and soaked in acetone solution for 12 hours, and then cleaned with deionized water and absolute ethanol in sequence. Put it in an oven at 100°C to dry for 0.5h, weigh it, put the base layer material into 2wt% hydrophobic agent and soak it for 5min, then take it out and dry it in the oven for 0.5h, repeat the soaking-drying process several times , until the content of the hydrophobic agent in the base layer reaches 20%, and finally put the base layer in a muffle furnace and raise the temperature to 250°C for 0.5h heat treatment, then raise the temperature to 350°C and continue roasting for 0.5h,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com