Functional integrated absorbable guided tissue regeneration membrane and preparation method thereof

A technology for guiding tissue regeneration and regenerating membranes, applied in tissue regeneration, prostheses, non-woven fabrics, etc., can solve the problems of lack of osteogenic activity and antibacterial properties, poor mechanical properties of degradable membranes, uncontrollable degradation cycle, etc. Good mechanical properties and biocompatibility, improving biocompatibility, preventing overgrowth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

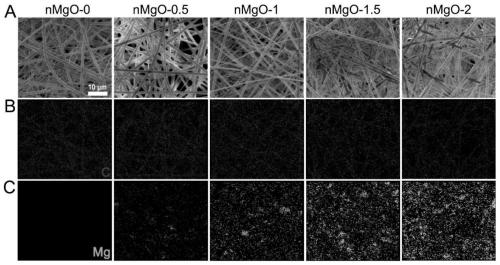

[0042] Weigh 0.8g of PLA (molecular weight 100,000, Jinan Daigang) and 0.2g of gelatin (25000-50000, Sigma) into 10ml of hexafluoroisopropanol solution, stir overnight on a magnetic stirrer, and configure A polymer solution A with a content of 10% was obtained.

[0043] Weigh 0.05g of nano-magnesium oxide particles (50nm, Aladdin) into polymer solution A, stir on a magnetic stirrer for 4h, ultrasonically vibrate for 60min, and then perform electrospinning to form a non-woven fabric with a size of 30x 30cm The cloth is the receiving device, the voltage is set to 15kV, the spinning rate is 3ml / h, the spinning is 2h, the receiving distance is 15cm, and an electrospun fiber membrane with a thickness of about 300μm is obtained.

[0044] Place the electrospun fiber membrane in a -80°C refrigerator for 30 minutes, and then dry it in a freeze dryer overnight to ensure that there is no residual solvent in the fiber membrane. The fiber membrane is recorded as nMgO-0.5 (indicating that ...

Embodiment 2

[0046] According to Example 1, the mass of nano-magnesium oxide particles was changed to 0.1 g, and the rest were the same as in Example 1 to obtain an electrospun fiber membrane with a thickness of about 300 μm, and the freeze-drying was also the same as in Example 1. The fiber membrane is recorded as nMgO-1 (meaning that the total mass ratio of the quality of nano magnesium oxide in the fiber membrane to the polylactic acid-gelatin is 10%).

Embodiment 3

[0048] According to Example 1, the mass of nano-magnesia particles was changed to 0.15 g, and the rest were the same as in Example 1 to obtain an electrospun fiber membrane with a thickness of about 300 μm, and the freeze-drying was also the same as in Example 1. The fiber membrane is recorded as nMgO-1.5 (representing that the total mass ratio of the quality of nano magnesium oxide in the fiber membrane to the polylactic acid-gelatin is 15%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com