Special pig manure charcoal for amino graft transformation, its preparation method and its application in the reuse of farmland water and nitrogen

A technology of pig manure charcoal and amino, applied in application, chemical instruments and methods, carbon preparation/purification, etc., can solve problems that restrict the efficient development of poultry and livestock breeding, and achieve high value-added utilization problems, reduce nitrogen pollution, Easy to apply effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

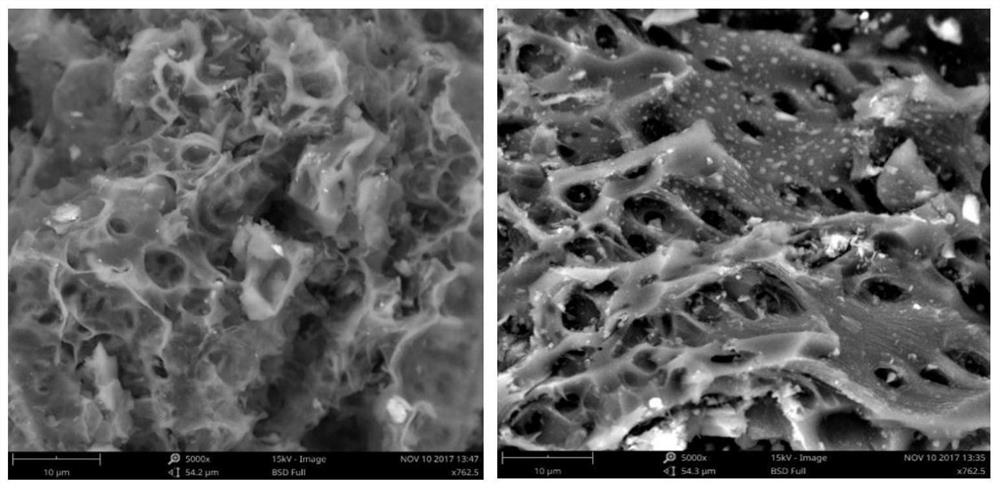

Image

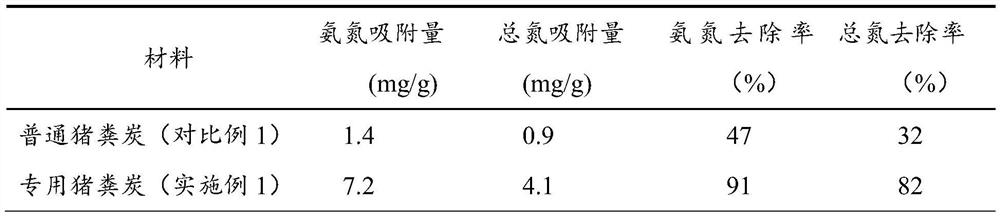

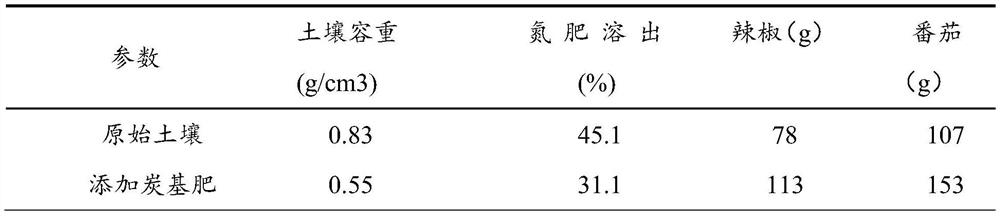

Examples

Embodiment 1

[0038] A preparation method of special pig manure charcoal for amino graft transformation, the method is specifically:

[0039] 1) Raw material drying: Dehydrate the raw pig manure to a moisture content of 80%-85%, using 1mol / L HNO 3For pickling, the stirrer is stirred slowly for 3 hours at a speed of 100-200r / min, stirred quickly for 1 hour at a speed of 500-600r / min, dried in an oven at 100°C for 12 hours, and crushed to a particle size of <0.1mm to obtain dry pig manure powder.

[0040] 2) Liquid nitrogen pretreatment and high temperature carbonization:

[0041] Dry pig manure powder is sealed with liquid nitrogen. The weight ratio of dry pig manure powder to liquid nitrogen is 2:1. The magnetic stirring speed is 300 rpm. The weight ratio of the powder is 2:1, and the addition is completed in 4 minutes, followed by washing with water, filtering, and drying in an oven at 100°C for 12 hours. The dried product is carbonized in a high-temperature tube furnace, the carbonizati...

Embodiment 2

[0050] Adopting the special-purpose pig manure charcoal of amino graft transformation that the embodiment 1 makes realizes the method for strengthening and reducing the nitrogen pollution of farmland dewatering, specifically:

[0051] The high-efficiency adsorption reactor is composed of three sequentially connected reaction pools, and the volume ratio of the first, second, and third reaction pools is 3:1:2. In the first reaction pool, special pig manure charcoal was added for amino graft transformation. In the method, the returned water from the farmland enters the pig manure charcoal high-efficiency adsorption reactor for treatment, and the reactor continuously flows into the water, and the hydraulic retention time is 48 hours.

[0052] The first reaction tank is used for rapid adsorption. There is a turbine agitator at the bottom with a rotation speed of 500r / min. Special pig manure charcoal for amino grafting transformation is put into the tank. The ratio of the volume of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com