Wear-resistant and corrosion-resistant protecting film and preparation method and application thereof

A protective film and corrosion-resistant technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of chemically unstable precursors, increase the difficulty of preparation process control, and affect the performance of the film. , to achieve the effect of improving protective performance and strong interface bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention provides a preparation method of the wear-resistant and corrosion-resistant protective film described in the above technical solution, comprising the following steps:

[0028] (1) Deposit metal Ta on the surface of the substrate by ion plating to form a thin film of metal Ta on the surface of the substrate;

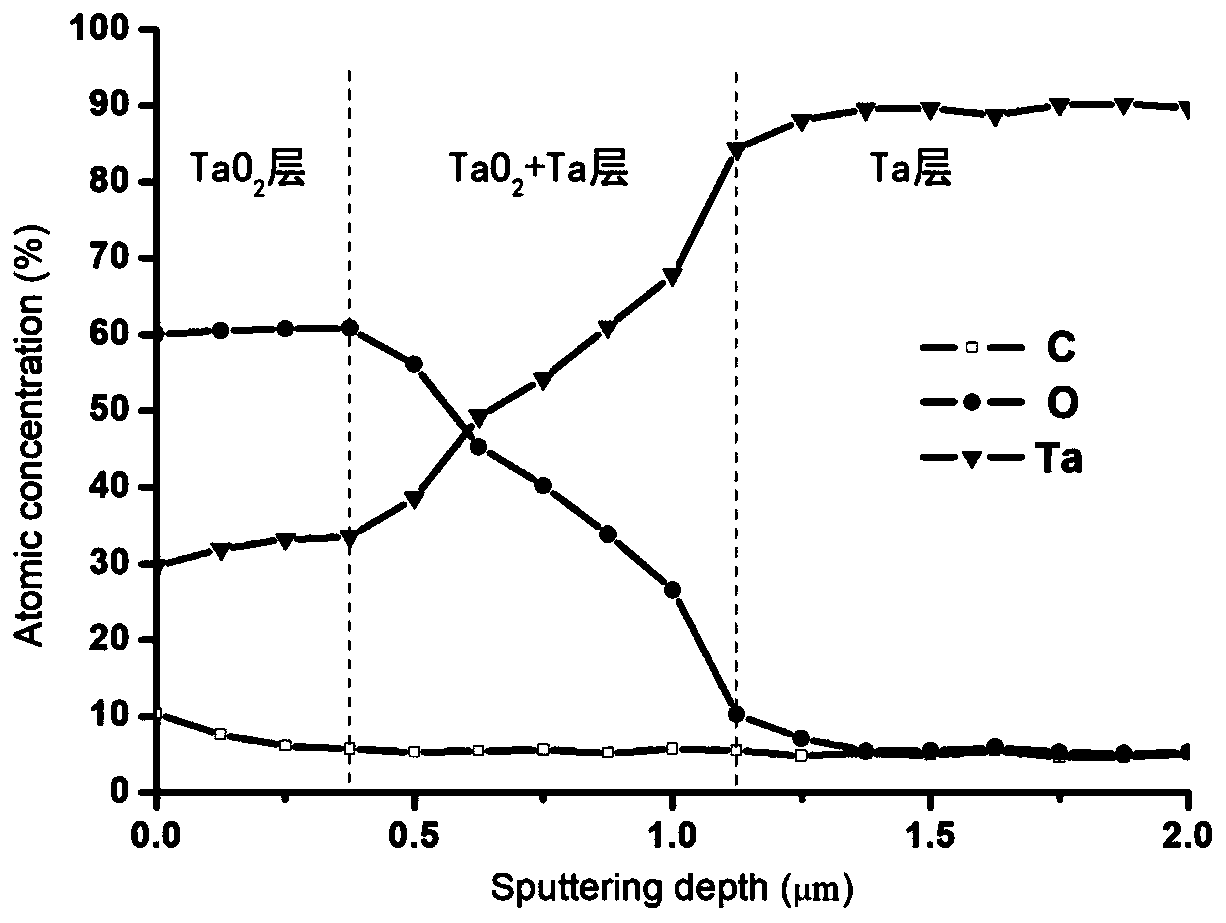

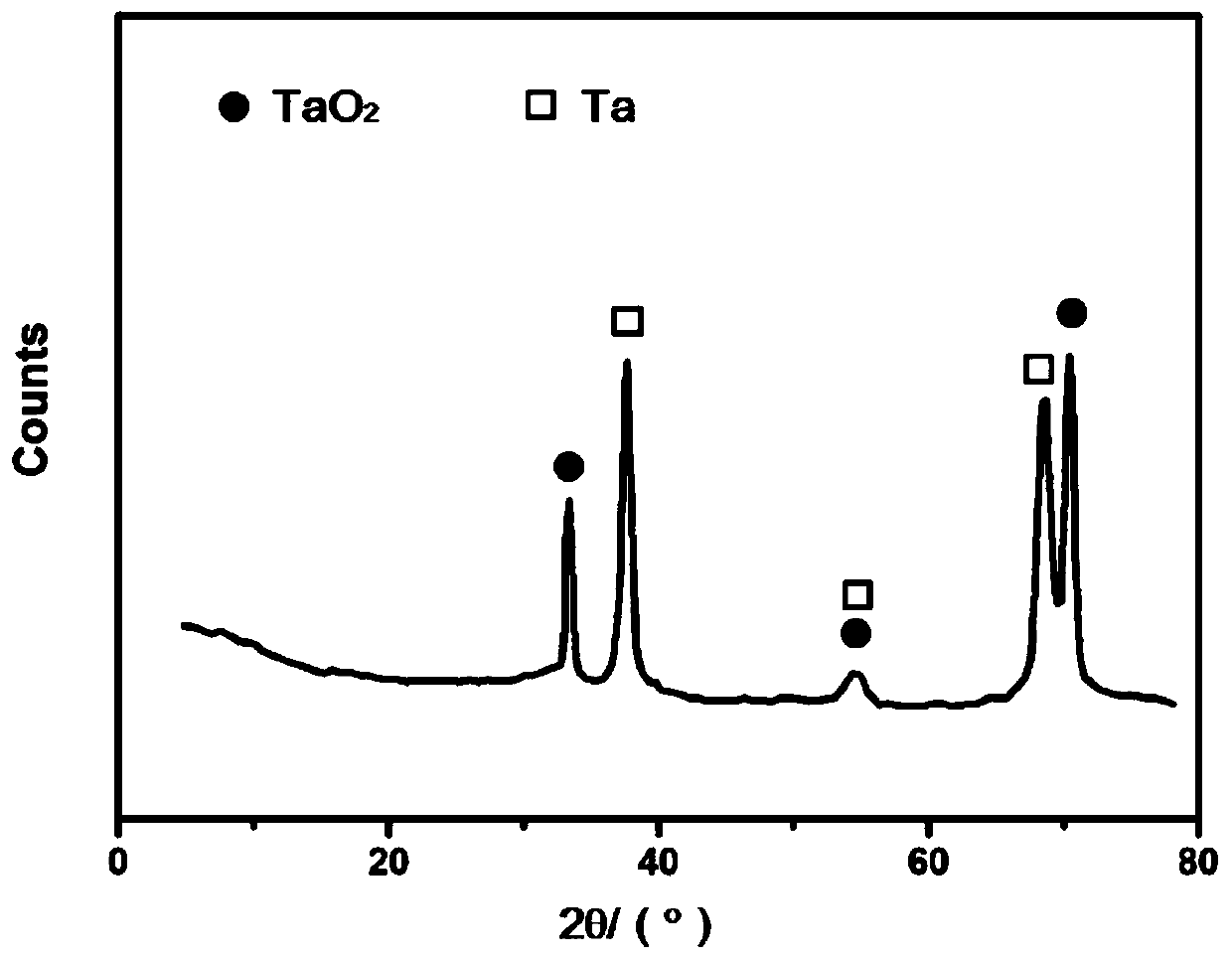

[0029] (2) irradiating the metal Ta thin film with an atomic oxygen beam to form a wear-resistant and corrosion-resistant protective film in situ on the surface of the substrate; the energy of the atomic oxygen beam is 0.1-2eV, and the irradiation time is 30-120min.

[0030] The invention adopts the ion plating method to deposit metal Ta on the surface of the substrate, and forms a metal Ta film on the surface of the substrate.

[0031] In the present invention, the substrate is preferably pretreated before depositing metal Ta. In the present invention, the substrate preferably includes at least one of TA1 titanium alloy, TA2 titanium alloy, ...

Embodiment 1

[0043] The instruments used include: ABS-1200 type multi-arc combined with unbalanced magnetron sputtering coating device; Simul-LEO-T 450 type space atomic oxygen effect ground simulation test device; the substrate is made of TC4 titanium alloy, and its geometric dimensions are:

[0044] (1) Surface polishing and cleaning of substrate

[0045] Use water sandpaper to grind and polish the surface of the substrate, so that the surface roughness of the substrate to be coated is better than 0.08 μm; then, use acetone, petroleum ether and absolute ethanol to clean the surface and polish the substrate sequentially; finally rinse with deionized water and quickly use nitrogen gas blow dry.

[0046] (2) Substrate installation and argon ion sputtering cleaning

[0047] Put the substrate sample cleaned in the previous step into the ABS-1200 multi-arc combined unbalanced magnetron sputtering coating device, so that the distance between the center of the substrate and the center of the ...

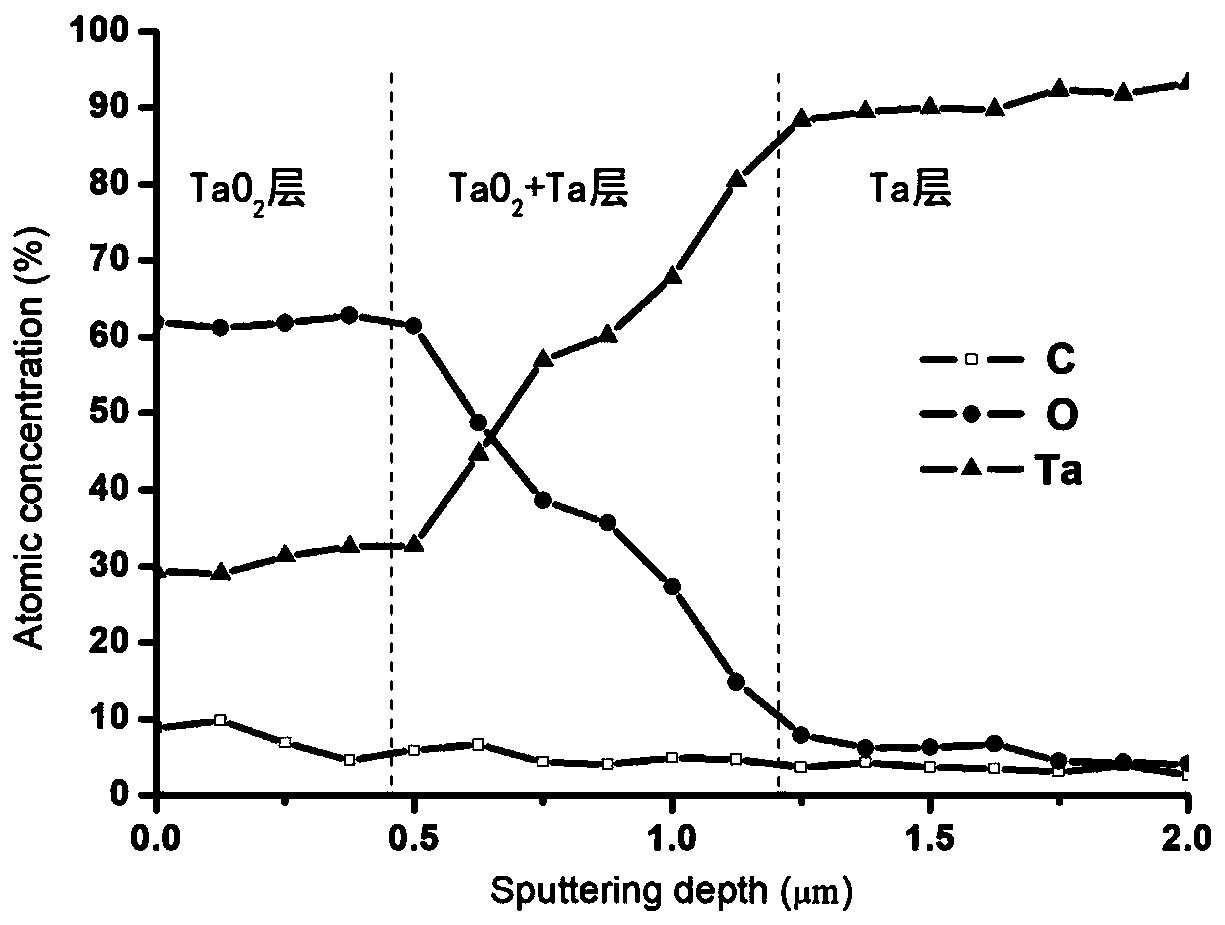

Embodiment 2

[0053] The instruments used include: ABS-1200 type multi-arc combined with unbalanced magnetron sputtering coating device; Simul-LEO-T 450 type space atomic oxygen effect ground simulation test device; the substrate is made of TC4 titanium alloy, and its geometric dimensions are:

[0054] (1) Surface polishing and cleaning of substrate

[0055] Use water sandpaper to grind and polish the surface of the substrate, so that the surface roughness of the substrate to be coated is better than 0.08 μm; then, use acetone, petroleum ether and absolute ethanol to clean the surface and polish the substrate sequentially; finally rinse with deionized water and quickly use nitrogen gas blow dry.

[0056] (2) Substrate installation and argon ion sputtering cleaning

[0057] Put the substrate sample cleaned in the previous step into the ABS-1200 multi-arc combined unbalanced magnetron sputtering coating device, so that the distance between the center of the substrate and the center of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com