Method for selectively metallizing oxide ceramic composite material

A technology of oxide ceramics and composite materials, applied in metal processing equipment, laser welding equipment, electrical components, etc., can solve the problems of weak interface bonding force, poor wettability between oxide ceramic materials and metal materials, etc. The effect of strong binding force and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

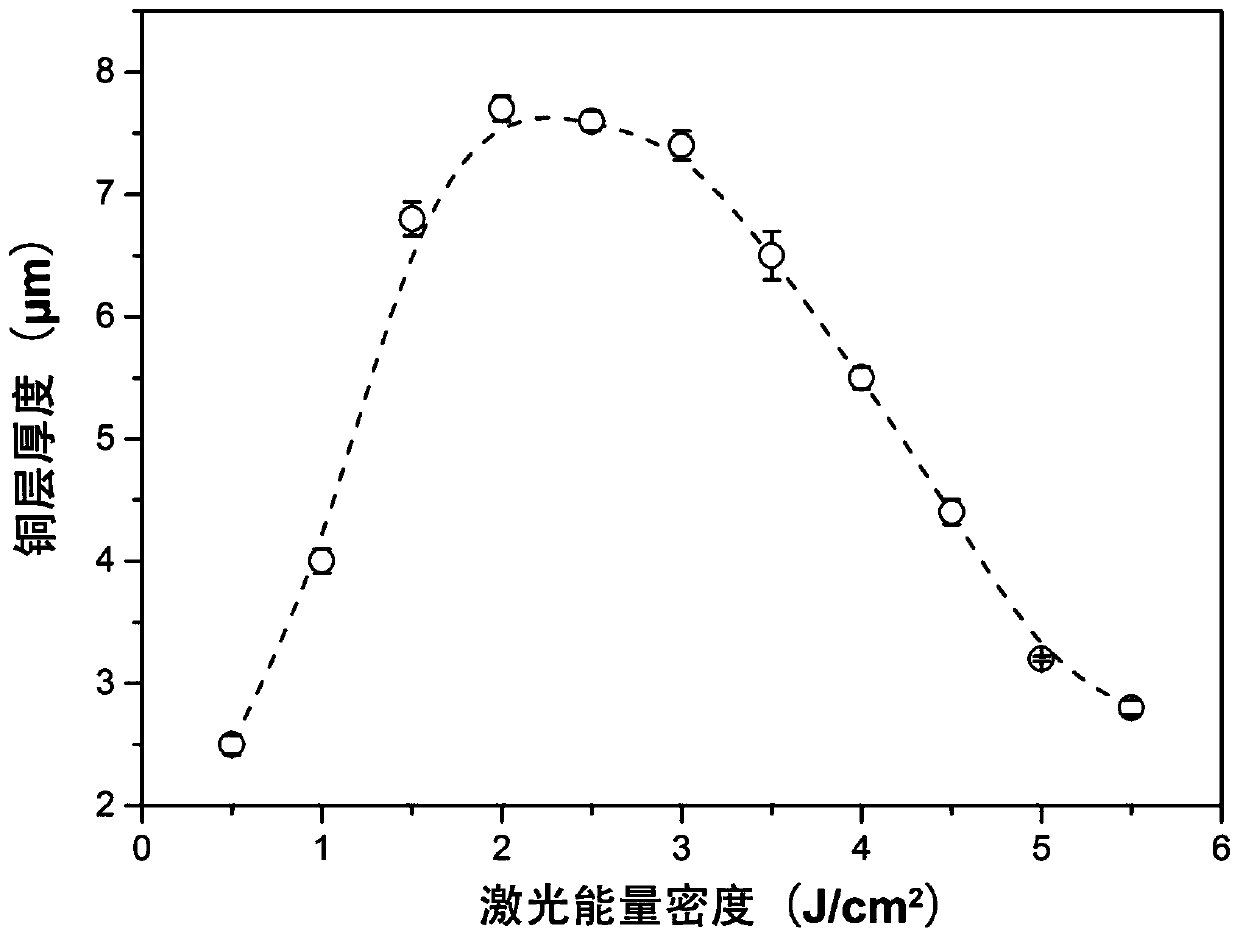

[0022] al 2 o 3 -Cu 2 Copper clad metallization of O composite materials: Al 2 o 3 and Cu 2 O batching according to mass ratio 96:4, dry mixing with agate ball grinding medium for 2 hours to obtain uniformly mixed powder, then put the powder into a steel mill of 50mm×50mm for cold pressing, the pressure is 50MPa, and then The green body is sintered in a vacuum furnace, and the furnace temperature is raised to 1630°C at a heating rate of 5°C / min, and the holding time is 4 hours to obtain Al 2 o 3 -Cu 2 O composite material, then use laser for surface treatment and wiring, laser energy density: 0.6-20j / cm 2 , and then use the standard copper plating solution (Yishun brand Q / YS.118) for copper sinking treatment. The relationship between the thickness of copper sinking and laser energy density is as follows: figure 2 shown.

Embodiment 2

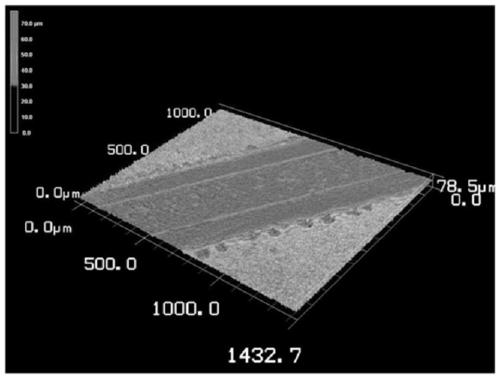

[0024] Copper clad metallization of 3YSZ-CuO composite materials: ZrO 2 -3%Y 2 o 3 (3YSZ) and CuO are mixed according to the mass ratio of 98:2, with agate balls and absolute alcohol as the grinding medium, mixed in a ball mill for 2 hours and then dried to obtain a uniformly mixed powder material, and then the powder is put into a 50mm Cold pressing was carried out in a steel abrasive tool of ×50mm at a pressure of 100MPa, and then the green body was sintered in a vacuum furnace, and the furnace temperature was raised to 1430°C at a heating rate of 5°C / min, and the holding time was 2 hours to obtain 3YSZ-CuO Composite material, remaining steps are identical with embodiment 1, carry out surface treatment and the surface of wiring with laser such as image 3 shown.

Embodiment 3

[0026] al 2 o 3 -NiO composite nickel clad metallization: the Al 2 o 3 Mix with NiO according to the mass ratio of 95:5, and dry mix with agate ball grinding medium for 1 hour to obtain a uniformly mixed powder, and then put the powder into a 50mm×50mm steel grinding tool for cold pressing at a pressure of 80MPa. Then the green body is sintered in a vacuum furnace, and the furnace temperature is raised to 1650°C at a heating rate of 5°C / min, and the holding time is 4 hours to obtain Al 2 o 3 -NiO composite material, then use laser for surface treatment and wiring, and then use standard nickel deposition solution (Yishun brand Q / YS.602) for nickel deposition treatment.

Description of drawings

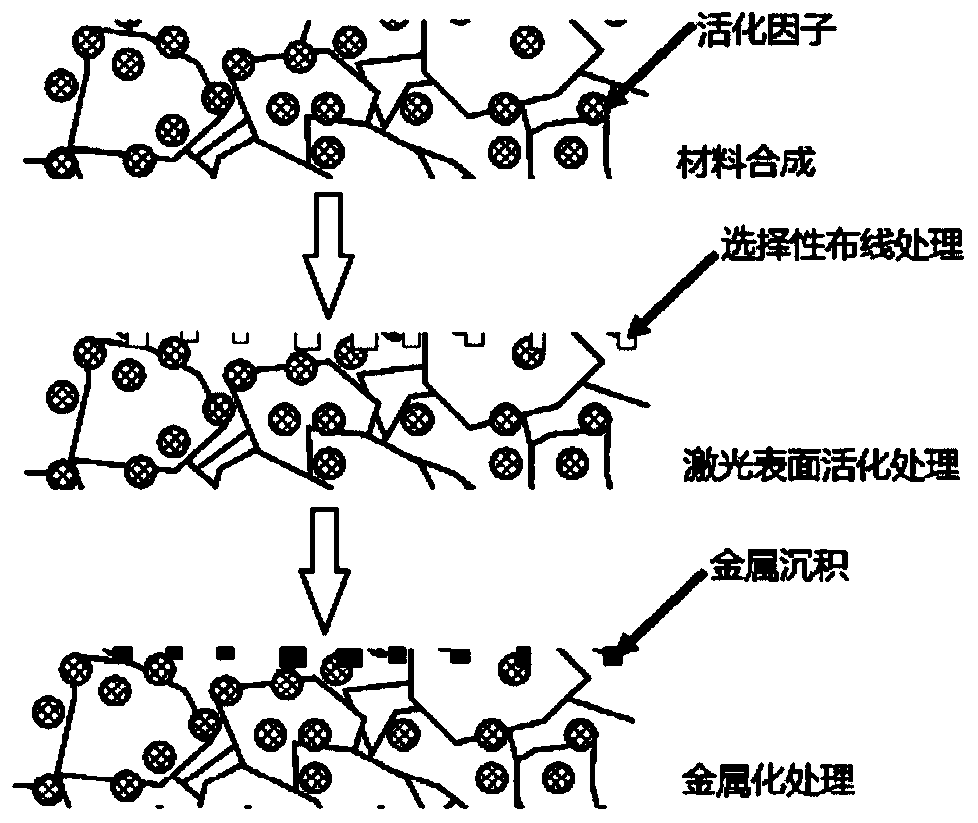

[0027] figure 1 : Schematic diagram of laser surface treatment and post-wiring metallization after adding activating factors in oxide ceramic materials.

[0028] figure 2 :Al 2 o 3 -Cu 2 The relationship between the thickness of deposited copper and the laser energy density ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com