Special fruit tree fertilizer produced from castor oil meal and preparation process thereof

The technology of castor oil and special fertilizer is applied in the field of special fertilizer for fruit trees and its preparation technology, which can solve the problems of waste of resources, affect the appearance of the environment, etc., and achieve the effects of lasting fertilizer effect, fertilizing soil and comprehensive nutrients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

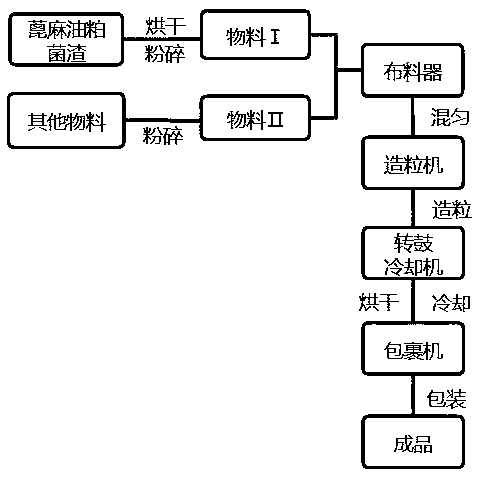

[0032] When applied on kiwi fruit trees, a kind of special fertilizer for fruit trees produced by castor oil meal in parts by weight: 62 parts of castor oil meal, 7 parts of urea, 14 parts of superphosphate, 5 parts of potassium chlorate, 9 parts of compound bacteria residue, synergistic 1 part of agent, 2 parts of adhesive.

[0033] Step 1: Take 62 parts of castor oil meal and 9 parts of composite fungus residue, dry them at a temperature of 50-60°C, grind them, mix them evenly, and pass them through a 50-mesh sieve to obtain material I;

[0034] Step 2: Accurately weigh 7 parts of urea, 14 parts of superphosphate, 5 parts of potassium chlorate, 1 part of synergist, and 2 parts of adhesive, grind them and add them to a mixer to obtain material II;

[0035] Step 3: Feed material Ⅰ and material Ⅱ into the distributor and evenly distribute them in the extrusion granulator, granulate to obtain granules, the particle size is 3.8-4.4mm, if the particle size is unqualified, return t...

Embodiment 2

[0042] When applied on apple trees, the ratio of special fertilizer for fruit trees is: 61 parts of castor oil meal, 11 parts of urea, 20 parts of superphosphate, 3 parts of potassium chlorate, 5 parts of compound bacteria residue, 2 parts of synergist, adhesive 1 serving.

[0043] Step 1: Take 61 parts of castor oil meal and 5 parts of composite fungus residue, dry them at a temperature of 50-60°C, grind them, mix them evenly, and pass them through a 50-mesh sieve to obtain material I;

[0044] Step 2: Accurately weigh 11 parts of urea, 20 parts of superphosphate, 3 parts of potassium chlorate, 2 parts of synergist, and 1 part of adhesive, grind them and add them to a mixer to obtain material II;

[0045] Step 3: Feed material Ⅰ and material Ⅱ into the distributor and evenly distribute them in the extrusion granulator, granulate to obtain granules, the particle size is 3.8-4.4mm, if the particle size is unqualified, return to the granulator for re-granulation ;

[0046] Ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com