Art pigment and preparation method thereof

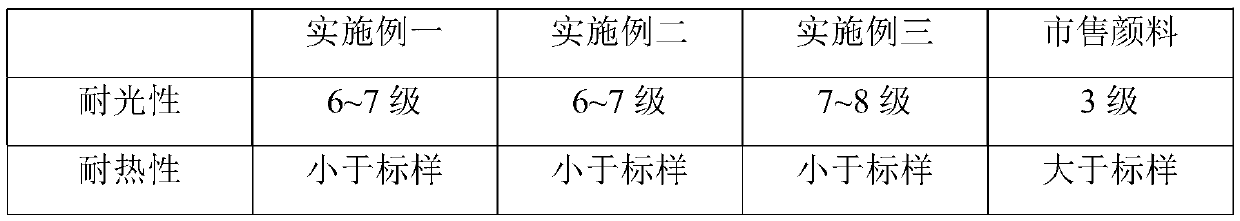

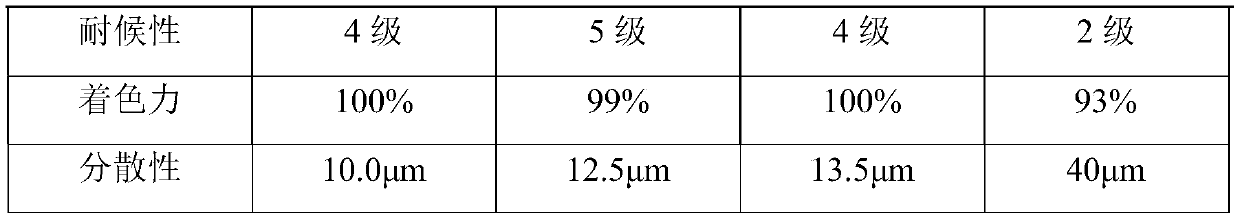

A pigment and art technology, applied in the field of pigments, can solve the problems of light fastness, heat resistance, poor weather resistance, uneven pigment quality, limited color and hue, etc., and achieve good gloss, improved adhesion, and bright color. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of art paint, it is made by the raw material of following weight ratio:

[0024] 20 parts of guar gum, 10 parts of distilled water, 20 parts of natural carotene, 8 parts of methyl methacrylate, 7 parts of tert-butyl hydroquinone, 8 parts of polyethylene glycol, 4 parts of titanium dioxide, 7 parts of talcum powder , 12 parts of acrylic latex, 3 parts of nonionic polyoxyethylene fatty alcohol ether, and 3 parts of sodium polyacrylate.

[0025] The preparation method of this art paint, comprises the following steps:

[0026] (1) Put the guar gum into distilled water and heat it to 80°C for 30 minutes, stir to dissolve, and control the stirring speed to 350r / min to make an adhesive glue.

[0027] (2) Methyl methacrylate, tert-butyl hydroquinone, Polyethylene Glycol are added in the adhesive glue solution that step (1) makes, and the control stirring speed is 200r / min, stirring temperature is 70°C, stir evenly to obtain a colloid.

[0028] (3) Add acrylic latex to...

Embodiment 2

[0032] A kind of art paint, it is made by the raw material of following weight ratio:

[0033] 30 parts of guar gum, 15 parts of distilled water, 18 parts of chrysanthemum yellow, 5 parts of methyl methacrylate, 6 parts of tert-butyl hydroquinone, 6 parts of polyethylene glycol, 2 parts of titanium dioxide, 5 parts of talcum powder , 9 parts of acrylic latex, 2 parts of sodium fatty alcohol polyoxyethylene ether sulfate, 2 parts of sodium polyacrylate.

[0034] The preparation method of this art paint, comprises the following steps:

[0035] (1) Put the guar gum into distilled water and heat it to 80°C for 40 minutes, stir to dissolve, and control the stirring speed to 400r / min to make an adhesive glue.

[0036] (2) Methyl methacrylate, tert-butylhydroquinone, Polyethylene Glycol are added in the adhesive glue solution that step (1) makes, be 250r / min, stirring temperature is 250r / min with stirring speed Stir evenly at 60°C to obtain a colloid.

[0037] (3) Add acrylic late...

Embodiment 3

[0041] A kind of art paint, it is made by the raw material of following weight ratio:

[0042] 20 parts of guar gum, 10 parts of distilled water, 20 parts of purple cabbage pigment, 8 parts of methyl methacrylate, 7 parts of tert-butyl hydroquinone, 8 parts of polyethylene glycol, 4 parts of titanium dioxide, 7 parts of talcum powder , 12 parts of acrylic latex, 3 parts of polyethylene glycol stearyl ether, and 3 parts of sodium polyacrylate.

[0043] The preparation method of this art paint, comprises the following steps:

[0044] (1) Heat the guar gum in distilled water, control the heating temperature to 85°C, and heat for 60 minutes, stir and dissolve under heating conditions, control the stirring speed to 400r / min, and make adhesive glue.

[0045] (2) Methyl methacrylate, tert-butyl hydroquinone, Polyethylene Glycol are added in the adhesive glue solution that step (1) makes, and the control stirring speed is 300r / min, stirring temperature is Stir at 45°C to obtain a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com