A kind of preparation method of three-dimensional porous structure dye-sensitized solar cell counter electrode

A solar cell and dye sensitization technology, applied in the field of solar cell preparation, can solve the problems that the platinum counter electrode cannot meet the requirements of flexible battery preparation, it is difficult to control the thickness of the deposited film, and it is not suitable for industrialization, so as to reduce electron-hole recombination probability, short preparation period and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

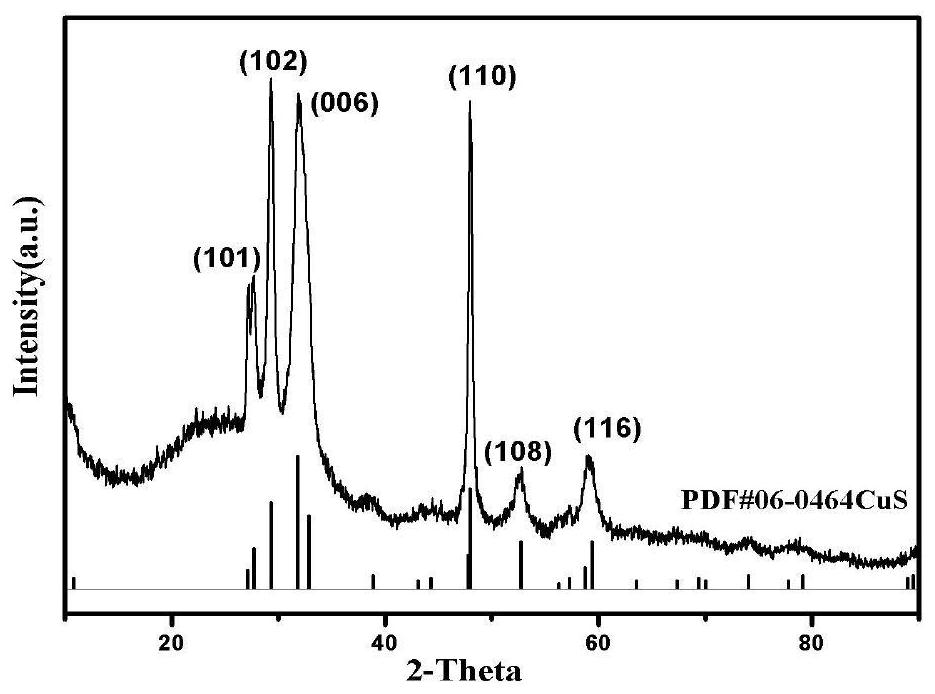

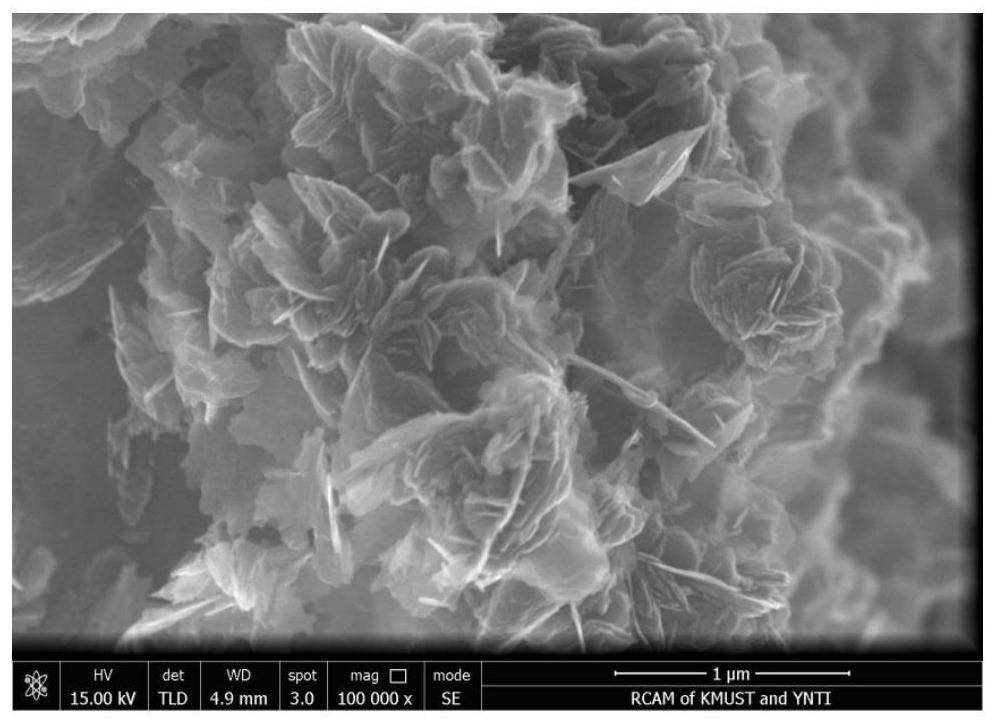

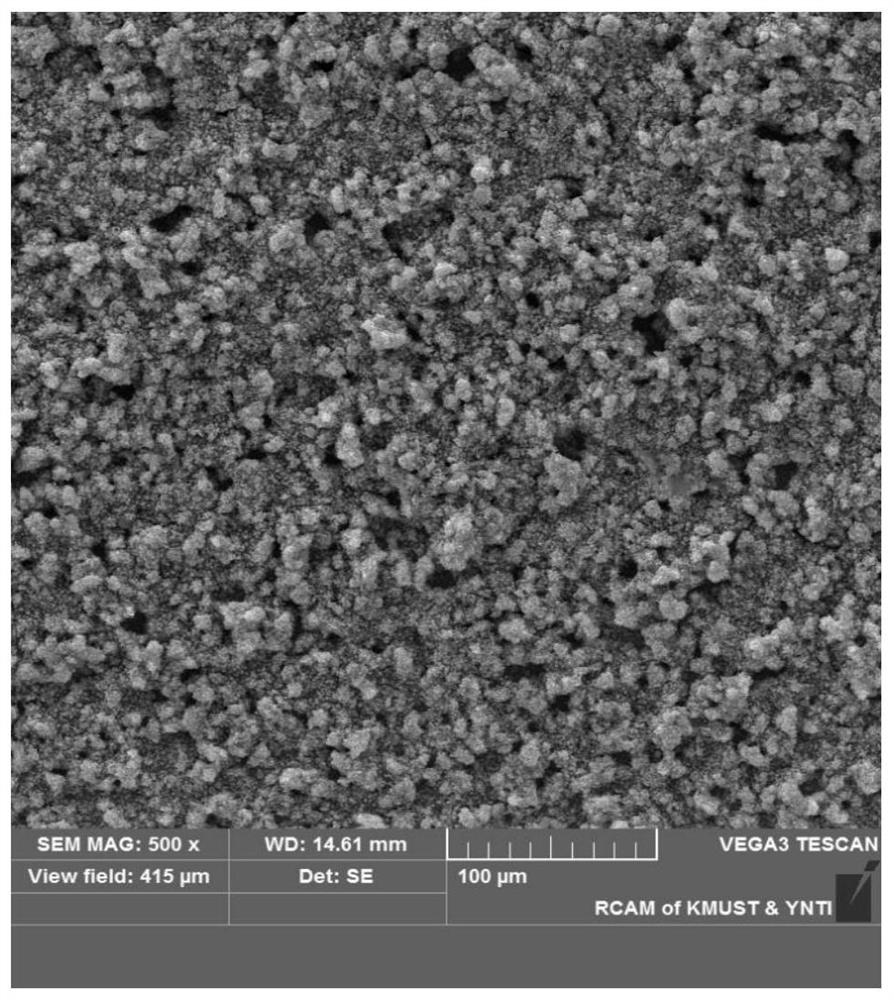

[0029] (1) Weigh 2mmol of CuCl 2 2H 2 O, 2mmol of thiourea was added to the three-necked flask, and then 40mL of ethylene glycol was added and stirred evenly with ultrasonic waves until it was completely dissolved.

[0030] (2) put the mixed solution obtained in step (1) into the magnetic stirring heater, install the condensing pipe and pass into cold water, then carry out the first step heating, the temperature is set to 130 ℃, the stirring speed is 300r / min, and the temperature is kept for 30min ; Carry out the second step of heating, set the temperature to 150 °C, the stirring speed is 300 r / min, and the temperature is kept for 30 min.

[0031] (3) after completing the two-step heating reaction, the obtained solution is naturally cooled to room temperature, then dispensed into a centrifuge tube and added with absolute ethanol (the volume ratio of absolute ethanol / mixed solution is 1.5) to mix well, put into a centrifuge for centrifugation, The centrifugation speed was 10,...

Embodiment 2

[0039] (1) Weigh 2mmol of CuCl 2 2H 2 O, 2mmol of n-dodecanethiol was added to the three-necked flask, and then 60mL of ethylene glycol was added to ultrasonically stir evenly until it was completely dissolved.

[0040] (2) put the mixed solution obtained in step (1) into the magnetic stirring heater, install the condensing pipe and pass into cold water, then carry out the first step of heating, the temperature is set to 120 ° C, the stirring speed is 400 r / min, and the temperature is kept for 50 min ; Carry out the second step of heating, set the temperature to 170°C, stir at a speed of 400r / min, and keep the temperature for 60min.

[0041] (3) after completing the two-step heating reaction, the obtained solution is naturally cooled to room temperature, then dispensed into a centrifuge tube and added with absolute ethanol (the volume ratio of absolute ethanol / mixed solution is 1.5) to mix evenly, put into a centrifuge for centrifugation , the centrifugation speed is 10000r / ...

Embodiment 3

[0049] (1) Weigh 2mmol of CuCl 2 2H 2 O, 2 mmol of carbon disulfide was added to the three-necked flask, then 60 mL of ethylene glycol was added and stirred evenly with ultrasonic waves until it was completely dissolved.

[0050] (2) put the mixed solution obtained in step (1) into the magnetic stirring heater, install the condensing pipe and pass into cold water, then carry out the first step of heating, the temperature is set to 120 ° C, the stirring speed is 400 r / min, and the temperature is kept for 50 min ; Carry out the second step of heating, set the temperature to 200 °C, the stirring speed is 400 r / min, and the temperature is kept for 60 min.

[0051] (3) after completing the two-step heating reaction, the obtained solution is naturally cooled to room temperature, then dispensed into a centrifuge tube and added with absolute ethanol (the volume ratio of absolute ethanol / mixed solution is 1.5) to mix evenly, put into a centrifuge for centrifugation , the centrifugati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com