Preparation method of carbon quantum dot modified LiFePO4 positive electrode material

A cathode material, carbon quantum dot technology, applied in the direction of positive electrode, active material electrode, battery electrode, etc., can solve the problems of unsatisfactory binding effect of lithium iron phosphate, low expansion coefficient of carbon layer, and reduced rate performance, etc., to achieve excellent Effect of rate capability, improved conductivity, and easy modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

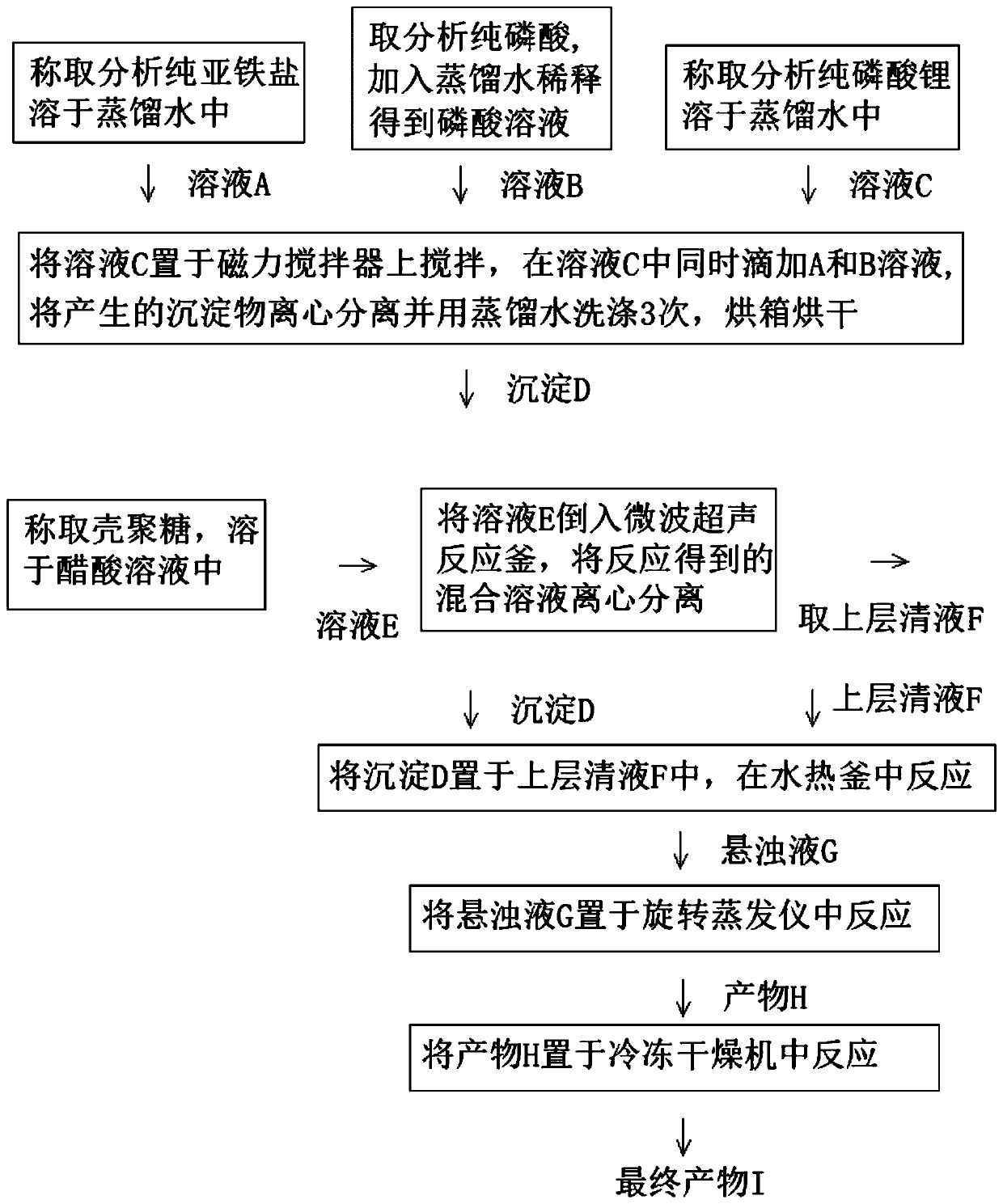

[0050] see figure 1 , a carbon quantum dot modified LiFePO4 positive electrode material preparation method, comprising the following steps:

[0051] S1. Weigh 5 g of analytically pure ferrous salt and dissolve it in 50 mL of distilled water to obtain solution A;

[0052] S2, get analytically pure phosphoric acid 5ml, add distilled water and obtain diluting to 60mL and obtain phosphoric acid solution B;

[0053] S3. Weigh 10 g of analytically pure lithium phosphate and dissolve it in 50 mL of distilled water to obtain solution C;

[0054] S4, solution C is placed on self-sterilizing magnetic stirrer, rotating speed 400r / min, dropwise A and B solution simultaneously in solution C, stir while adding dropwise, the precipitate produced is centrifuged and washed 3 times with distilled water, Oven drying at 60°C to obtain precipitate D;

[0055] S5, take chitosan 5g, be dissolved in 50mL mass fraction 20% acetic acid solution, obtain mixed solution E;

[0056] S6. Stir the soluti...

Embodiment 2

[0061] see figure 1 , a carbon quantum dot modified LiFePO4 positive electrode material preparation method, comprising the following steps:

[0062] S1. Weigh 25 g of analytically pure ferrous salt and dissolve it in 100 mL of distilled water to obtain solution A;

[0063] S2, get analytically pure phosphoric acid 25ml, add distilled water and obtain and dilute to 60mL and obtain phosphoric acid solution B;

[0064] S3. Weigh 25g of analytically pure lithium phosphate and dissolve it in 80mL of distilled water to obtain solution C;

[0065] S4, solution C is placed on self-sterilizing magnetic stirrer, rotating speed 400r / min, dropwise A and B solution simultaneously in solution C, stir while adding dropwise, the precipitate produced is centrifuged and washed 3 times with distilled water, Oven drying at 60°C to obtain precipitate D;

[0066] S5, weigh chitosan 10g, be dissolved in 50mL mass fraction 40% acetic acid solution, obtain mixed solution E;

[0067] S6. Stir the s...

Embodiment 3

[0072] see figure 1 , a carbon quantum dot modified LiFePO4 positive electrode material preparation method, comprising the following steps:

[0073] S1. Weigh 10 g of analytically pure ferrous salt and dissolve it in 75 mL of distilled water to obtain solution A;

[0074] S2, get analytically pure phosphoric acid 15ml, add distilled water and obtain and dilute to 60mL and obtain phosphoric acid solution B;

[0075] S3. Weigh 15g of analytically pure lithium phosphate and dissolve it in 60mL of distilled water to obtain solution C;

[0076] S4, solution C is placed on self-sterilizing magnetic stirrer, rotating speed 400r / min, dropwise A and B solution simultaneously in solution C, stir while adding dropwise, the precipitate produced is centrifuged and washed 3 times with distilled water, Oven drying at 60°C to obtain precipitate D;

[0077] S5, take chitosan 5g, be dissolved in 50mL mass fraction 30% acetic acid solution, obtain mixed solution E;

[0078] S6. Stir the solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com