A silicon-based composite negative electrode material and its preparation method and application

A negative electrode material, silicon-based technology, applied in the field of silicon-based composite negative electrode material and its preparation, can solve the problems of restricting the migration rate of lithium ions, loss of electrochemical connection of active materials, low electrical conductivity, etc., and achieves insignificant volume expansion effect. Good cycle stability, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

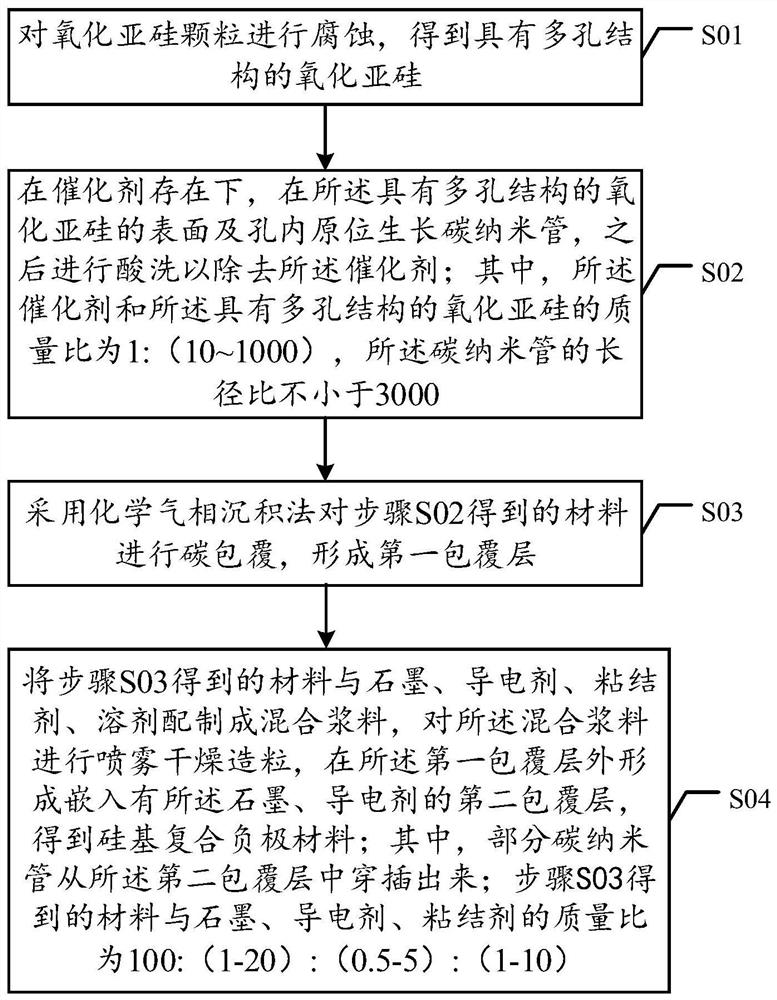

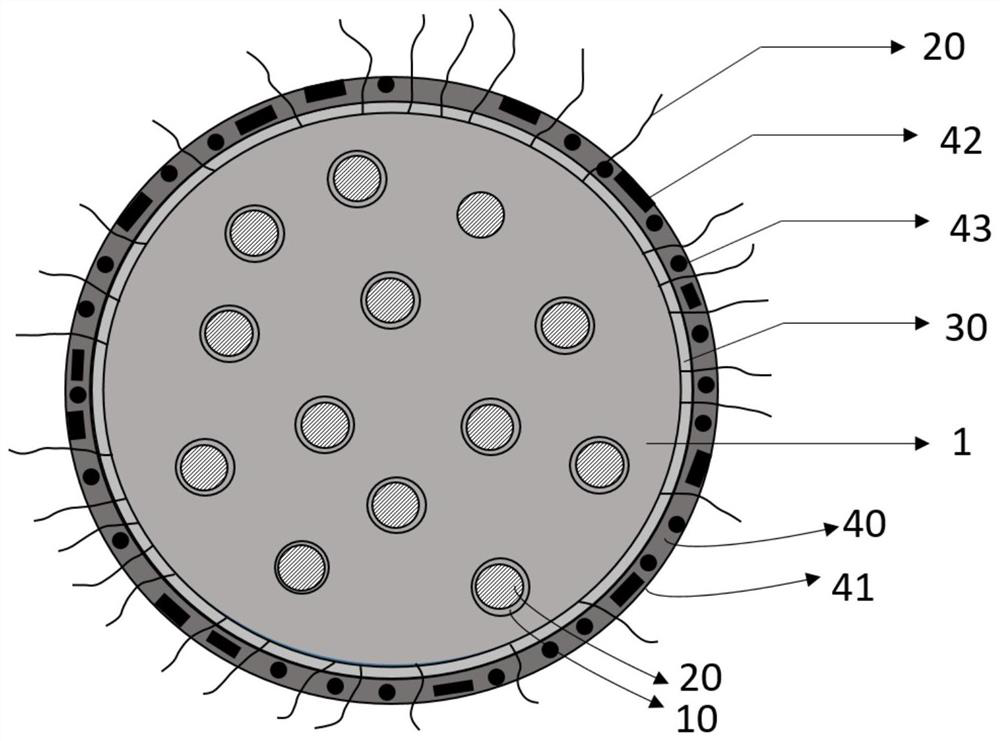

[0054] see figure 1 , one embodiment of the present invention provides a method for preparing a silicon-based composite negative electrode material, comprising the following steps:

[0055] S01, corroding silicon oxide particles to obtain silicon oxide with a porous structure;

[0056] S02. In the presence of a catalyst, carbon nanotubes are grown in situ on the surface and in the pores of the silicon oxide with a porous structure, and then pickled to remove the catalyst; wherein, the catalyst and the porous structure The mass ratio of silicon oxide is 1:(10-1000), and the aspect ratio of the carbon nanotubes is not less than 3000;

[0057] S03, carbon-coating the material obtained in step S02 by chemical vapor deposition to form a first coating layer;

[0058] S04, prepare the material obtained in step S03 with graphite, conductive agent, binder, and solvent to form a mixed slurry; spray-dry and granulate the mixed slurry, and form an embedded material outside the first coa...

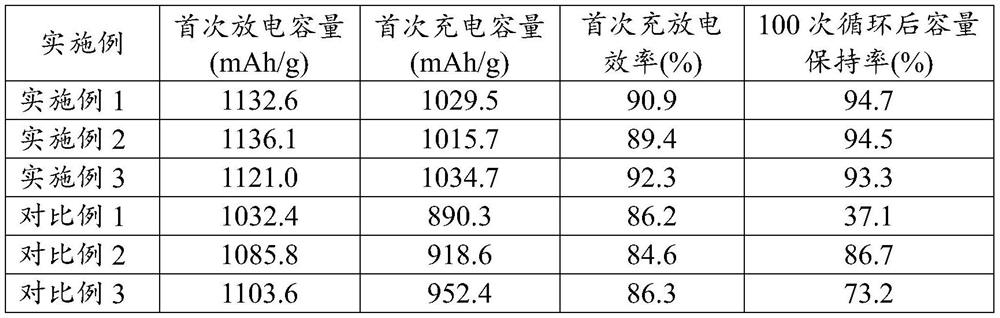

Embodiment 1

[0062] A method for preparing a silicon-based composite negative electrode material, comprising the following steps:

[0063] (1) Take amorphous silicon oxide with an average particle size D50 of 5 μm and add it to a hydrofluoric acid solution with a mass concentration of 10%, and carry out corrosion reaction for 1 hour while stirring with ultrasonic waves. After the corrosion is completed, filter the reaction mixture with suction , and the solid obtained by suction filtration was washed with pure water until the pH of the washing liquid was 7, and then dried in an oven at 110°C to obtain a porous silicon-based matrix, that is, silicon oxide with a porous structure;

[0064] (2) The iron powder with a particle size of 150nm and the above-mentioned porous silicon-based substrate are mechanically fused according to a mass ratio of 1:99, the fusion machine speed is 4500rpm, and the fusion time is 10min, so that the iron powder is evenly distributed on the surface of the porous sil...

Embodiment 2

[0070] A method for preparing a silicon-based composite negative electrode material, comprising the following steps:

[0071](1) Take amorphous silicon oxide with an average particle size D50 of 5 μm and add it to a hydrofluoric acid solution with a mass concentration of 20%, and carry out corrosion reaction for 0.5 h while stirring with ultrasonic waves. After the corrosion is completed, pump the reaction mixture The solid obtained by suction filtration was washed with pure water until the pH of the washing solution was 7, and then dried in an oven at 110°C to obtain a porous silicon-based matrix, that is, silicon oxide with a porous structure.

[0072] (2) According to the mass ratio of 3:97, the catalyst with a particle size of 100nm (specifically, a mixture of iron powder and nickel powder) is mechanically fused with the above-mentioned porous silicon-based substrate. The fusion machine speed is 3500rpm, and the fusion time is 20min. The catalyst powder is evenly distribut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com