Virus-killing mask and preparation method of mask filter layer

A virus-killing and filter layer technology, applied in the manufacture of rayon, single-component polyolefin rayon, clothing, etc., can solve the problems of sterilization, virus-killing rate and air permeability, bulkiness, increased breathing burden and Problems such as work pressure, sterilizing, and virus-killing performance are not ideal enough to achieve the effect of facilitating large-scale production, simple and controllable production process, and good bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

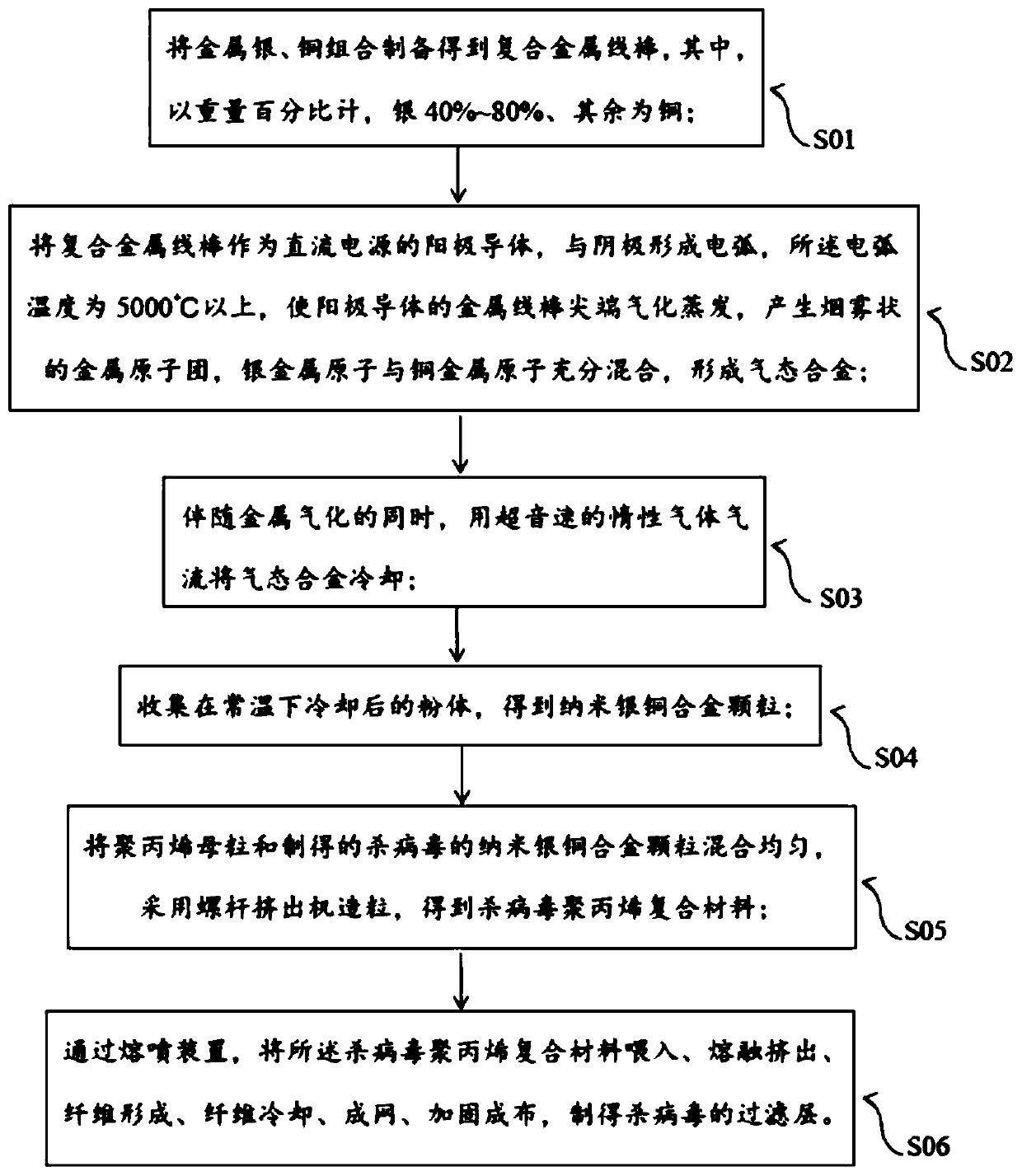

[0046] On the other hand, the preparation method of the filter layer of the aforementioned virus-killing mask, such as figure 1 shown, including the following steps:

[0047] S01. Prepare a composite metal wire rod by combining metal silver and copper, wherein, by weight percentage, silver is 40%-80%, and the rest is copper.

[0048] In a preferred embodiment, metal silver and metal copper wires are braided and rolled into a composite metal wire rod, wherein, by weight percentage, silver is 60% to 80% and the rest is copper.

[0049] S02. Use the composite metal wire rod as the anode conductor of the DC power supply to form an arc with the cathode. The temperature of the arc is above 5000°C, so that the tip of the metal wire rod of the anode conductor is vaporized and evaporated to produce smoky metal atom groups, silver metal atoms Fully mixed with copper metal atoms to form a gaseous alloy.

[0050] In a preferred embodiment, the composite metal wire rod is used as the ano...

Embodiment 1

[0067] A preparation method for a virus-killing mask filter layer, comprising the following steps:

[0068] S01, braiding silver metal wire and copper metal wire into a mixed metal wire with a diameter of 6mm, which is cold-rolled and rolled into a composite metal wire rod with a diameter of 5mm; wherein, in terms of weight percentage, silver is 40%, and the rest is copper. The purity of said metal silver and copper wire is 99.9%, and the diameter of said silver wire and copper wire is 0.4mm.

[0069] S02. Use the composite metal wire rod as the anode conductor of the DC power supply. Under the conditions of a DC voltage of 36 volts and a current of 1050 amps, an arc with a temperature of 5500 ° C and a length of 30 mm is formed with the cathode to make the tip of the metal wire rod of the anode conductor gas Evaporation produces smoky metal atom clusters, and the silver metal atoms and copper metal atoms are fully mixed to form a gaseous alloy.

[0070] S03. Along with metal...

Embodiment 2

[0075] A preparation method for a virus-killing mask filter layer, comprising the following steps:

[0076] S01. Weaving silver wire and copper wire into a mixed metal wire with a diameter of 7 mm, and cold rolling and calendering into a composite metal wire rod with a diameter of 5 mm; wherein, in terms of weight percentage, 60% of silver and the rest are copper. The purity of said metal silver and copper wire is 99.9%, and the diameter of said silver wire and copper wire is 0.5mm.

[0077] S02. Use the composite metal wire rod as the anode conductor of the DC power supply. Under the conditions of a DC voltage of 36 volts and a current of 1050 amps, an arc with a temperature of 5800 ° C and a length of 30 mm is formed with the cathode to make the tip of the metal wire rod of the anode conductor gas Evaporation produces smoky metal atom clusters, and the silver metal atoms and copper metal atoms are fully mixed to form a gaseous alloy.

[0078] S03. Along with metal vaporizat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com