Complex multi-metal rare earth ore beneficiation separation and enrichment method

A separation enrichment and multi-metal technology, applied in the field of mineral processing, can solve the problems of increasing the difficulty of hydrometallurgy separation, and the grade cannot reach the metallurgical concentrate, so as to achieve the effect of reducing the amount of ore, reducing the content and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

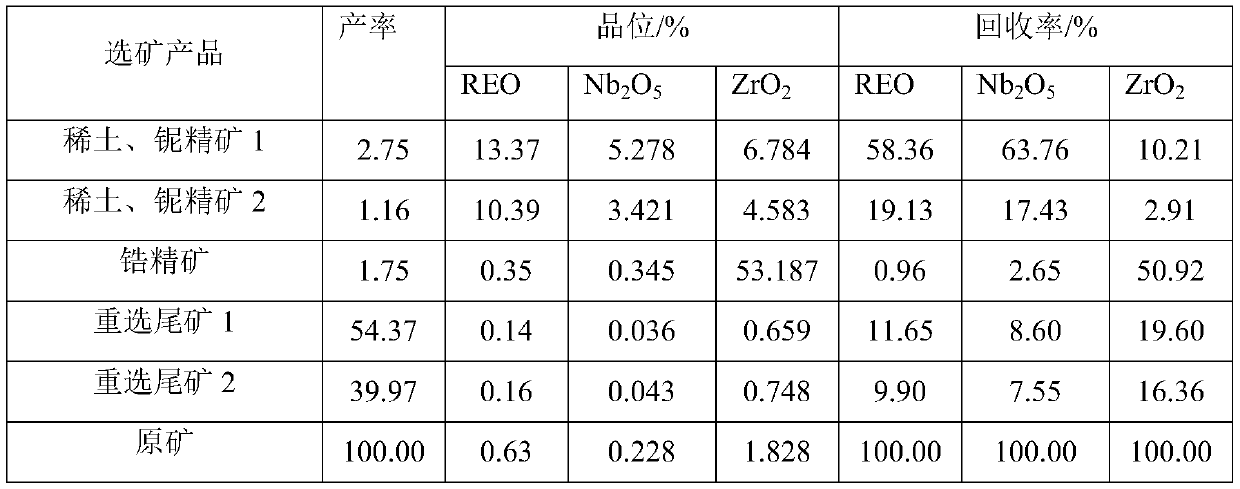

Embodiment 1

[0037] The Balzhe Deposit (also known as the 801 Mine) is a super-large rare rare earth metal deposit. The useful minerals mainly include pyroyl-yttrium, zircon, columbite, pyrochlore, black rare gold, garnet, Monazite, bastnaesite, iron thorium, etc., of which the former three are the main ones, the gangue minerals mainly contain albite, plagioclase, quartz, aionite, and albino. REO grade 0.63%, Nb 2 O 5 Grade 0.23%, ZrO 2 Grade 1.8%.

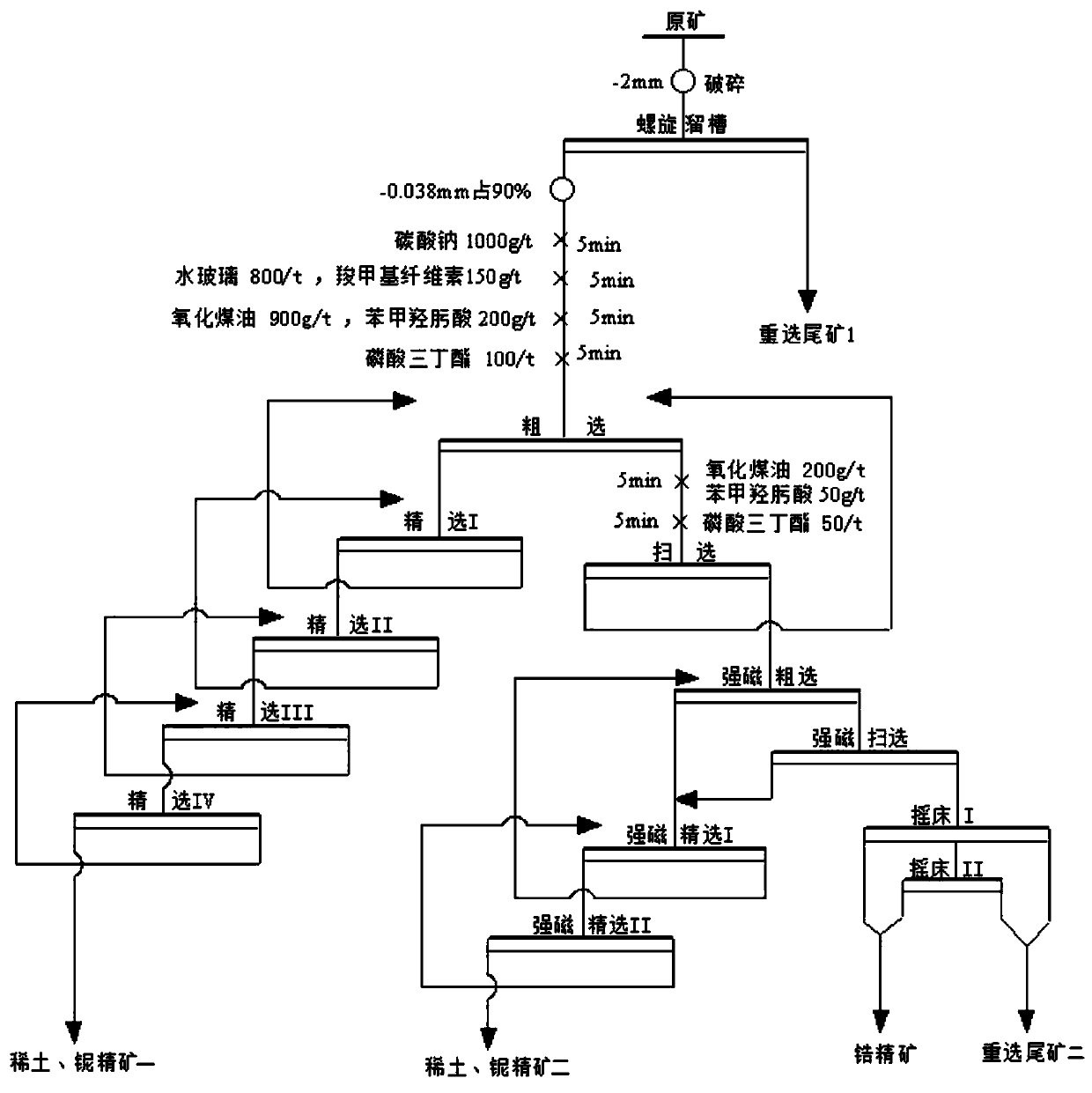

[0038] (1) First, the ore is finely crushed to 3mm, and the spiral chute is used for sorting, and the coarse concentrate and the tailing 1 are obtained.

[0039] (2) Grind the gravity separation coarse concentrate to a fineness of -0.038 accounting for 50%, adjust the slurry concentration to 35%, and adjust the temperature to 30°C, then transfer the slurry to the flotation tank; add 1000g to the slurry / t sodium carbonate, stir for 15min; add water glass 800g / t, carboxymethylcellulose 200g / t, stir for 15min, add 800g / t sodium fluorosilicate, stir ...

Embodiment 2

[0045] The Balzhe Deposit (also known as the 801 Mine) is a super-large rare rare earth metal deposit. The useful minerals mainly include pyroyl-yttrium, zircon, columbite, pyrochlore, black rare gold, garnet, Monazite, bastnaesite, iron thorium, etc., of which the former three are the main ones, the gangue minerals mainly contain albite, plagioclase, quartz, aionite, and albino. REO grade 0.63%, Nb 2 O 5 Grade 0.23%, ZrO 2 Grade 1.8%.

[0046] (1) First, the ore is finely crushed to 2.5mm, and the spiral chute is used for sorting, and the coarse concentrate and the tailing 1 are obtained.

[0047] (2) Grind the gravity separation coarse concentrate to a fineness of -0.038 accounting for 80%, adjust the slurry concentration to 30%, and adjust the temperature to 35°C, then transfer the slurry to the flotation tank; add 1200g to the slurry / t sodium carbonate, stir for 10min; add water glass 1000g / t, carboxymethyl cellulose 250g / t, stir for 10min, add 1000g / t sodium fluorosilicate, ...

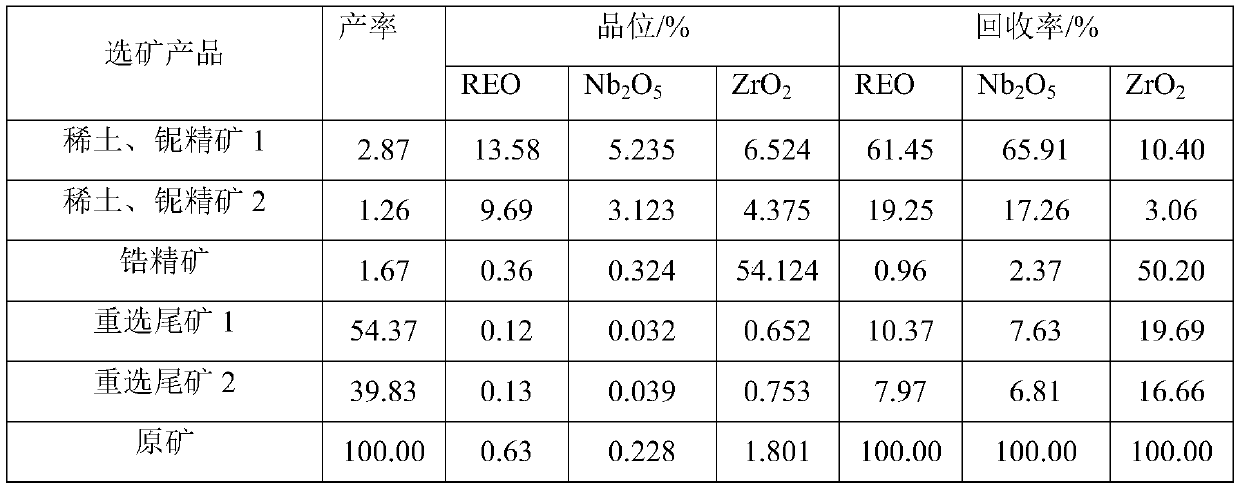

Embodiment 3

[0053] The Balzhe Deposit (also known as the 801 Mine) is a super-large rare rare earth metal deposit. The useful minerals mainly include pyroyl-yttrium, zircon, columbite, pyrochlore, black rare gold, garnet, Monazite, bastnaesite, iron thorium, etc., of which the former three are the main ones, the gangue minerals mainly contain albite, plagioclase, quartz, aionite, and albino. REO grade 0.63%, Nb 2 O 5 Grade 0.23%, ZrO 2 Grade 1.8%.

[0054] (1) First, the ore is finely crushed to 2mm, and the spiral chute is used for sorting, and the coarse concentrate and the tailing 1 are obtained.

[0055] (2) Grind the gravity separation coarse concentrate to a fineness of -0.038 accounting for 90%, adjust the slurry concentration to 25%, and adjust the temperature to 40°C, then transfer the slurry to the flotation tank; add 1500g to the slurry / t sodium carbonate, stir for 5min; add water glass 1200g / t, carboxymethyl cellulose 200g / t, stir for 5min, add 1200g / t sodium fluorosilicate, stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com