Preparation method of docusate sodium controlled-release tablet

A technology for docusate sodium and controlled-release tablets, which is applied in the field of preparation of docusate sodium controlled-release tablets, can solve the problems of difficulty in pulverizing raw materials, easy agglomeration of raw materials, uneven mixing, etc. Easy-to-implement, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

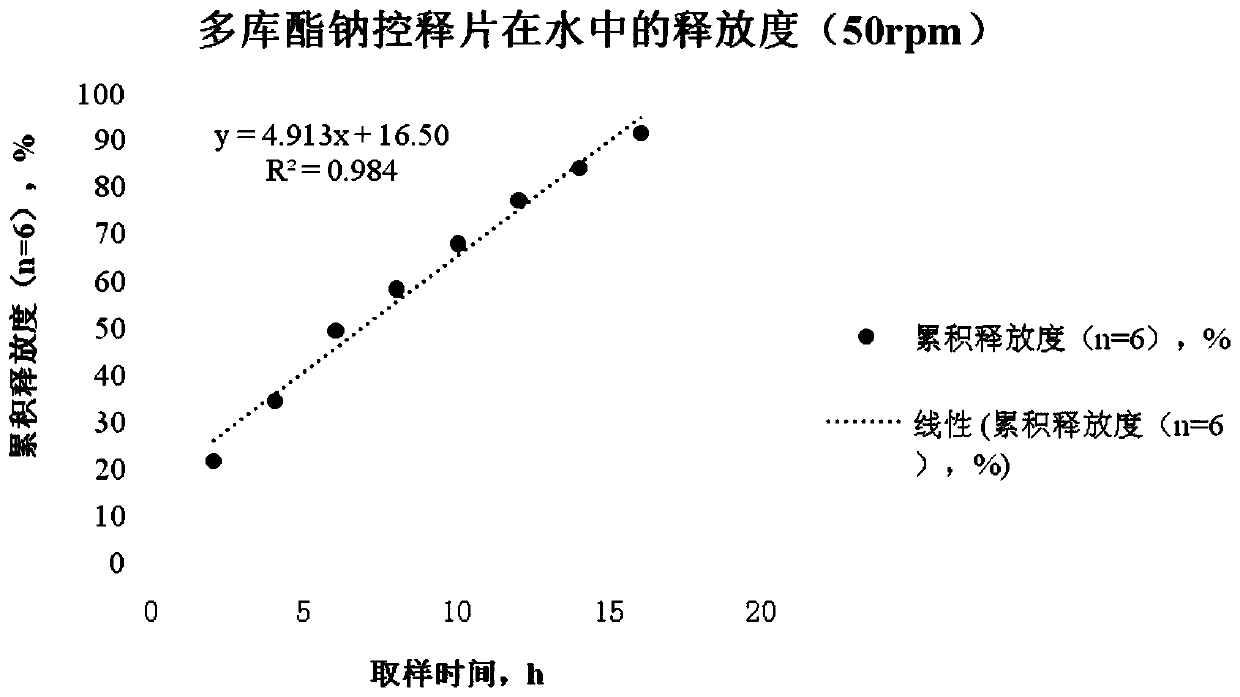

Image

Examples

Embodiment 1

[0022] The prescription composition of every 10,000 tablets of preparations is as follows: 2000 g of docusate sodium, 2300 g of microcrystalline cellulose PH101, 2300 g of hydroxypropyl methylcellulose K100M, 500 g of silicon dioxide, and 500 g of talcum powder.

[0023] Dissolve docusate sodium in 2.2kg of 90% ethanol as a wetting agent; add microcrystalline cellulose and hypromellose to the wet granulator, set the mixing knife speed to 75rpm, and the granulation knife speed 3000rpm, start the wet granulator, and mix for 3min; set the mixing knife speed to 140rpm, the granulation knife speed to 3000rpm, start the wet granulator, spray the wetting agent with a spray gun within 3min, and then stir for 2min; Granulate with a 20-mesh sieve; dry the wet granules with a fluidized granulation dryer. Set the air inlet temperature at 50°C, the outlet air temperature at 40°C, and dry for 30 minutes; use a 20-mesh sieve to sieve the granules; weigh the weight of the obtained dry granule...

Embodiment 2

[0025] The prescription composition of every 10000 tablets of preparation is as follows: 2000g of docusate sodium, 2700g of microcrystalline cellulose PH302, 2700g of hydroxypropyl methylcellulose K4M, 250g of silicon dioxide, and 250g of talcum powder.

[0026] Dissolve docusate sodium in 2.2kg of 90% ethanol as a wetting agent; add microcrystalline cellulose and hypromellose to the wet granulator, set the mixing knife speed to 70rpm, and the granulation knife speed 2800rpm, turn on the wet granulator, and mix for 6min; set the speed of the mixing knife to 130rpm, and the speed of the granulation knife to 2800rpm, turn on the wet granulator, and spray the wetting agent with a spray gun within 5min, and then stir for 2min; the obtained soft material is used Granulate with a 20-mesh sieve; dry the wet granules with a fluidized granulation dryer. Set the air inlet temperature to 50°C, the outlet air temperature to 40°C, and dry for 40 minutes; use a swing granulator to sieve the...

Embodiment 3

[0028] The prescription composition of every 10,000 tablets of preparations is as follows: 2000 g of docusate sodium, 2500 g of microcrystalline cellulose PH302, 2450 g of hydroxypropyl methylcellulose K4M, 300 g of silicon dioxide, and 300 g of talcum powder.

[0029] Dissolve docusate sodium in 2.2kg of 90% ethanol as a wetting agent; add microcrystalline cellulose and hypromellose to the wet granulator, set the mixing knife speed to 80rpm, and the granulation knife speed 3200rpm, turn on the wet granulator, and mix for 5min; set the speed of the mixing knife to 135rpm, and the speed of the granulation knife to 3200rpm, turn on the wet granulator, and spray the wetting agent with a spray gun within 5min, and then stir for 2min; the obtained soft material is used Granulate with a 20-mesh sieve; dry the wet granules with a fluidized granulation dryer. Set the air inlet temperature to 50°C, the outlet air temperature to 40°C, and dry for 35 minutes; use a swing granulator to si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com