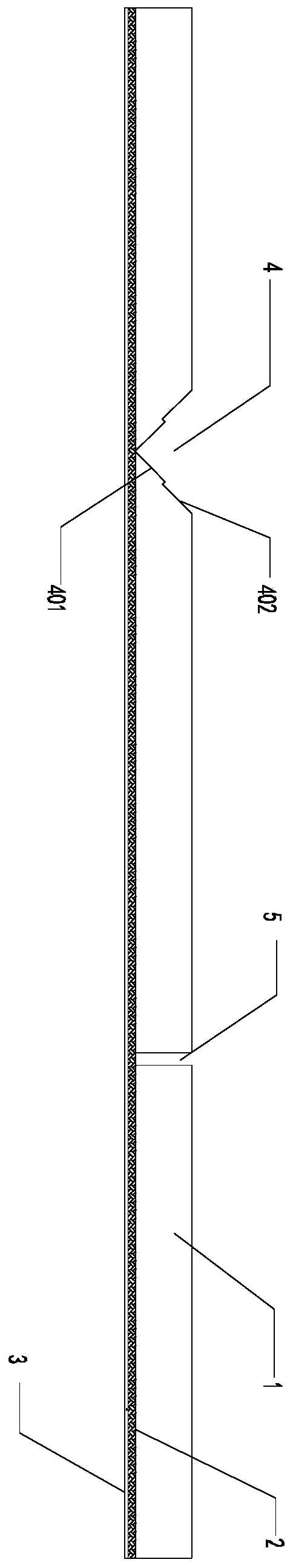

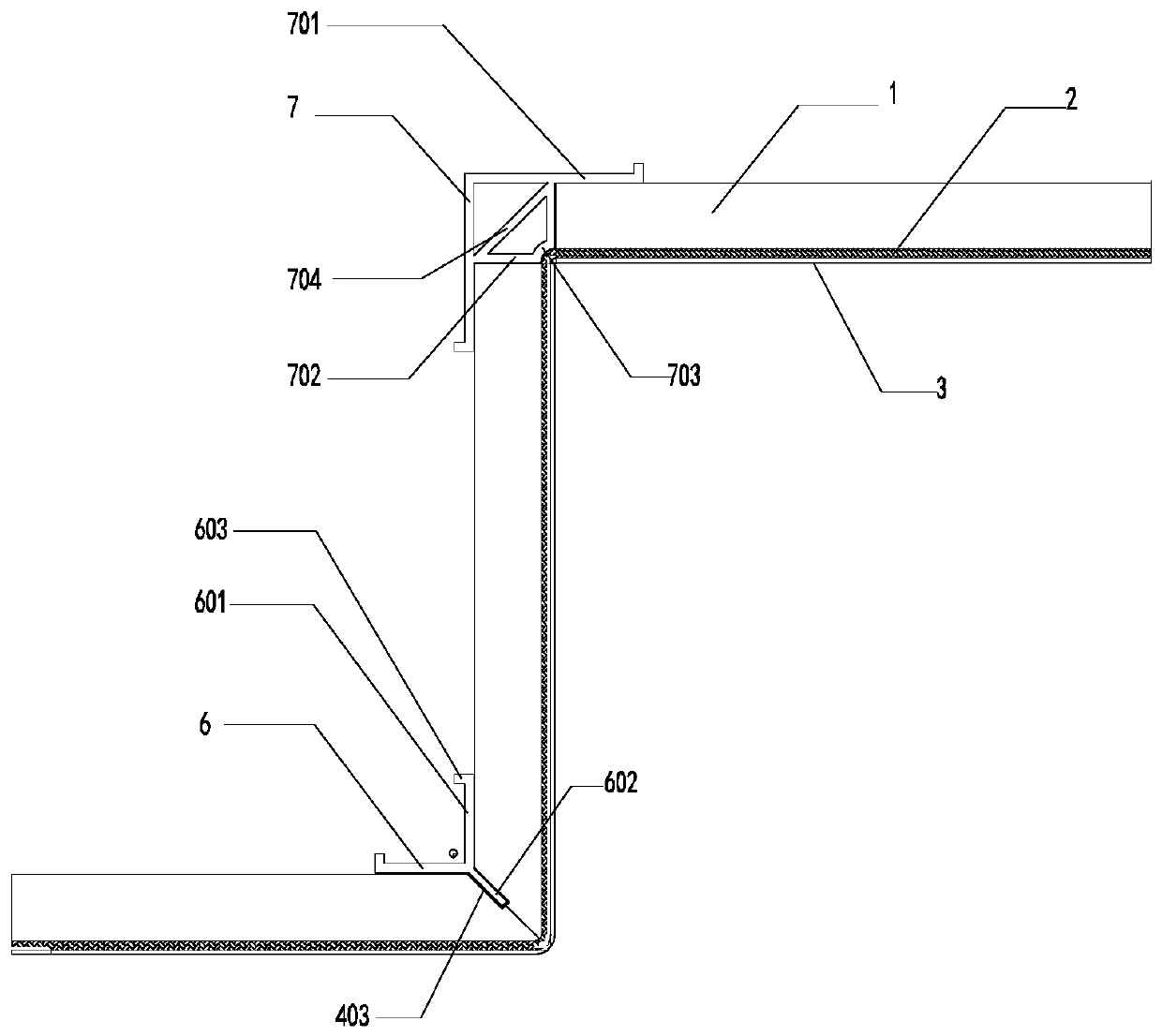

Angle-foldable PVC rigid-flexible composite board and preparation method thereof

A composite board, rigid-flexible technology, applied in the field of bendable PVC rigid-flexible composite board and its preparation, can solve the problems of poor connection stability of boards, affect the decorative effect, and cumbersome construction process, etc., achieve beautiful decorative effect, enhance mechanical properties, Stitching is simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A bendable PVC rigid-flexible composite board, in terms of mass fraction, the raw materials of the rigid layer include: 14% PVC resin, 18% bamboo wood powder, 49.7% calcium carbonate stone powder, 1.7% calcium-zinc composite stabilizer, 0.6% stearic acid , 0.5% polyethylene wax, 2.5% polyacrylate, 2.5% chlorinated polyethylene, 1.0% azodicarbonamide, 8% antibacterial filler and 1.5% sodium iodide; flexible layer raw materials include: 45% PVC resin , 38.2% calcium carbonate stone powder, 1.3% PVC softener, 3.5% calcium zinc composite stabilizer, 0.6% stearic acid, 0.6% polyethylene wax, 1.3% azodicarbonamide, 8% antibacterial filler and 1.5% sodium iodide. The thickness of the rigid layer is 8mm, the thickness of the flexible layer is 1mm, and the facing layer is PE film.

[0041] The antibacterial filler is nano-titanium dioxide grafted with hydroxyl-terminated polysiloxane sodium, and its preparation method is: first add nano-titanium dioxide into absolute ethanol, s...

Embodiment 2

[0047] A bendable PVC rigid-flexible composite board, in terms of mass fraction, the raw materials of the rigid layer include: 13% PVC resin, 15% bamboo wood powder, 58.8% calcium carbonate stone powder, 1.5% calcium-zinc composite stabilizer, 0.5% stearic acid , 0.4% polyethylene wax, 2% polyacrylate, 2% chlorinated polyethylene, 0.8% azodicarbonamide, 5% antibacterial filler and 1% sodium iodide; flexible layer raw materials include: 42% PVC resin , 45.7% calcium carbonate stone powder, 1.2% PVC softener, 3% calcium zinc composite stabilizer, 0.5% stearic acid, 0.4% polyethylene wax, 1.2% azodicarbonamide, 5% antibacterial filler and 1% sodium iodide. The thickness of the rigid layer is 7mm, the thickness of the flexible layer is 2mm, and the facing layer is PE film.

[0048] The antibacterial filler is nano-titanium dioxide grafted with hydroxyl-terminated polysiloxane sodium. Its preparation method is: first add nano-titanium dioxide into absolute ethanol, stir and mix ev...

Embodiment 3

[0054] A bendable PVC rigid-flexible composite board, in terms of mass fraction, the raw materials of the rigid layer include: 15% PVC resin, 20% bamboo wood powder, 42.7% calcium carbonate stone powder, 1.8% calcium-zinc composite stabilizer, 0.7% stearic acid , 0.6% polyethylene wax, 3% polyacrylate, 3% chlorinated polyethylene, 1.2% azodicarbonamide, 10% antibacterial filler and 2% sodium iodide; flexible layer raw materials include: 50% PVC resin , 30% calcium carbonate stone powder, 1.5% PVC softener, 4% calcium zinc composite stabilizer, 0.7% stearic acid, 0.6% polyethylene wax, 1.5% azodicarbonamide, 9.7% antibacterial filler and 2% sodium iodide. The thickness of the rigid layer is 7.5mm, the thickness of the flexible layer is 1.5mm, and the facing layer is PE film.

[0055]The antibacterial filler is nano-titanium dioxide grafted with hydroxyl-terminated polysiloxane sodium, and its preparation method is: first add nano-titanium dioxide into absolute ethanol, stir an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com