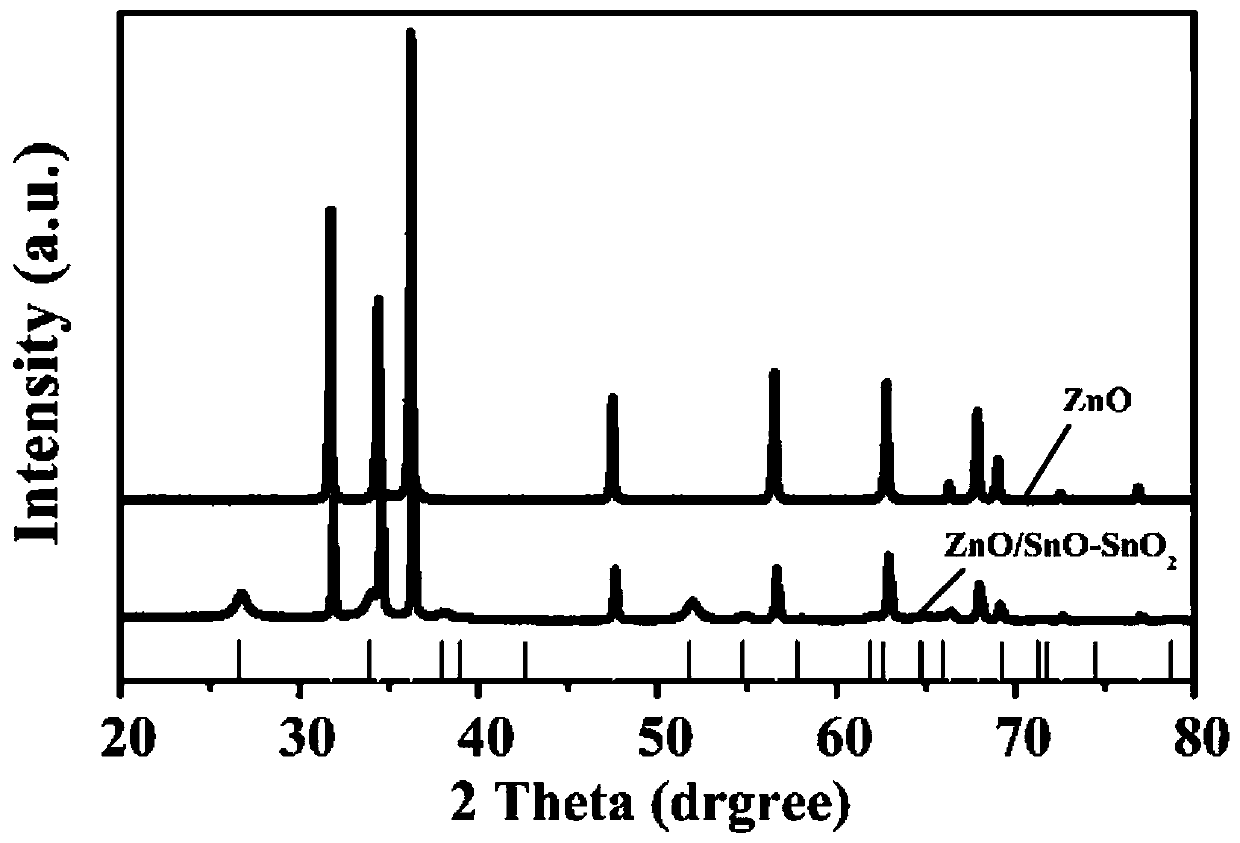

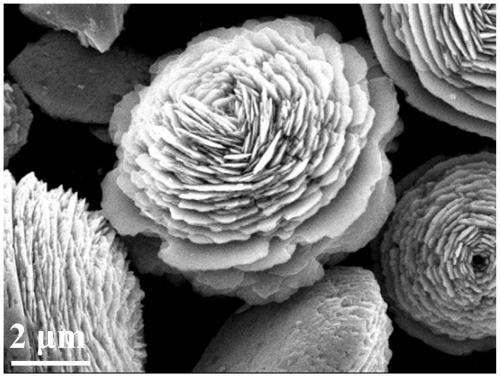

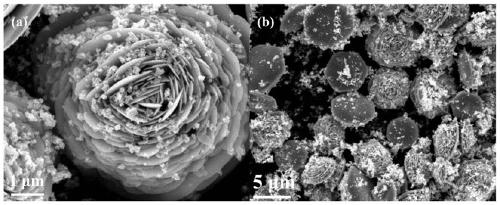

Camellia-flower-shaped ZnO/SnO-SnO2 composite material as well as preparation method and application thereof

A technology of composite materials and camellia, which is applied in the direction of analyzing materials, material resistance, and material analysis by electromagnetic means, can solve the problems of low sensitivity and high working temperature of amine sensors, and achieve improved sensitivity and selectivity, high response, and preparation low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The camellia-shaped ZnO / SnO-SnO of this embodiment 2 The preparation method of the composite material is as follows:

[0031] (1) Weigh 1mmol of hexamethylenetetramine, add 30ml of absolute ethanol and 10ml of deionized water, and ultrasonically dissolve for 10min to form a uniform and stable aqueous solution;

[0032] (2) Weigh 1 mmol of stannous chloride and add it to the aqueous solution and stir for 1 hour, then add 1.5 mmol of urea, and stir again for 1 hour until the solution forms a suspension;

[0033](3) Put the suspension into an autoclave with a polytetrafluoroethylene liner and seal it, react at a constant temperature of 120°C for 12h, and then cool naturally to room temperature. The product was washed three times with distilled water and absolute ethanol, dried at 60°C for 12 hours, and calcined at 400°C for 2 hours in an inert atmosphere to obtain SnO-SnO 2 Hybrid nanomaterials.

[0034] (4) Weigh 1mmol of Sapamine A cationic surfactant, add 30ml of abs...

Embodiment 2

[0038] The camellia-shaped ZnO / SnO-SnO of this embodiment 2 The preparation method of the composite material is as follows:

[0039] (1) Weigh 1mmol of hexamethylenetetramine, add 30ml of absolute ethanol and 10ml of deionized water, and ultrasonically dissolve for 10min to form a uniform and stable aqueous solution;

[0040] (2) Weigh 1 mmol of stannous chloride and add it to the aqueous solution and stir for 1 hour, then add 1 mmol of urea, and stir again for 1 hour until the solution forms a suspension;

[0041] (3) Put the suspension into an autoclave with a polytetrafluoroethylene liner and seal it, react at a constant temperature of 120°C for 12h, and then cool naturally to room temperature. The product was washed three times with distilled water and absolute ethanol, dried at 60°C for 12 hours, and calcined at 400°C for 2 hours in an inert atmosphere to obtain SnO-SnO 2 Hybrid nanomaterials.

[0042] (4) Weigh 1mmol of sodium succinate anionic surfactant (AOT), add 3...

Embodiment 3

[0047] The camellia-shaped ZnO / SnO-SnO of this embodiment 2 The preparation method of the composite material is as follows:

[0048] (1) Weigh 0.6mmol of hexamethylenetetramine, add 30ml of absolute ethanol and 10ml of deionized water, and ultrasonically dissolve for 10min to form a uniform and stable aqueous solution;

[0049] (2) Weigh 1 mmol of stannous chloride and add it to the aqueous solution and stir for 1 hour, then add 1 mmol of urea, and stir again for 1 hour until the solution forms a suspension;

[0050] (3) Put the suspension into an autoclave with a polytetrafluoroethylene liner and seal it, react at a constant temperature of 120°C for 12h, and then cool naturally to room temperature. The product was washed three times with distilled water and absolute ethanol, dried at 60°C for 12h, and calcined at 400°C for 1h in an inert atmosphere to obtain SnO-SnO 2 Hybrid nanomaterials.

[0051] (4) Weigh 1mmol of CTAC cationic surfactant, add 30ml of absolute ethanol a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com