Non-enzymatic biosensor based on metal-modified porous boron-doped diamond electrode and preparation method and application of non-enzymatic biosensor

A boron-doped diamond and biosensor technology, applied in the field of non-enzyme biosensor preparation, can solve the problems of quality control and production cost of enzyme-based sensors, and achieve the best detection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

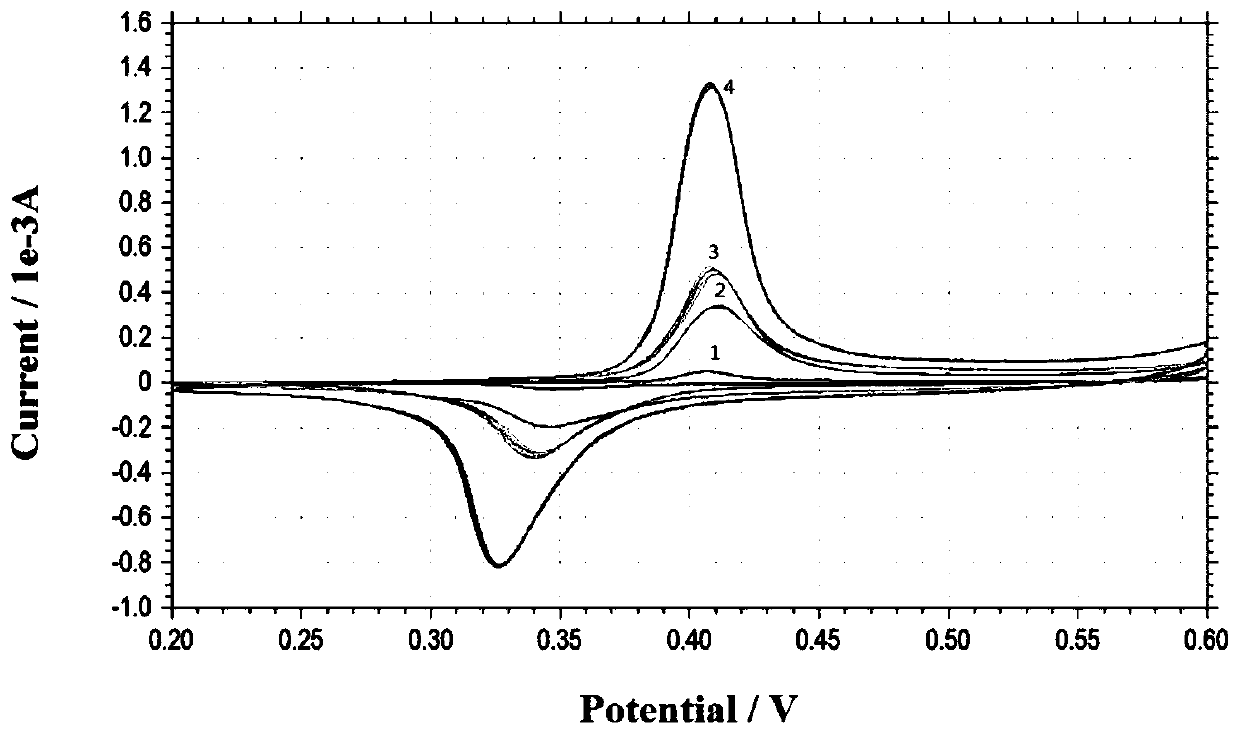

Examples

Embodiment 1

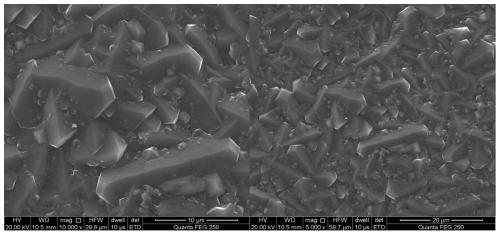

[0052] Step 1. Preparation of boron-doped diamond film. First place the silicon wafer substrate in an acetone solution, ultrasonically clean it for 5-20 minutes to remove surface oil stains; For the growth of boron diamond, the number of hot wire turns during the growth process is 10-20 turns, the temperature of the hot wire is controlled at 2000-2500°C, the surface temperature of the substrate is 700-900°C, and the gas ratio is methane / borane / hydrogen equal to 1 / 49 / 0.3, the chamber pressure is about 2.5-5 kPa, the grain size of the grown diamond film is 5-10 microns in diameter, and the film thickness ranges from 5-20 microns.

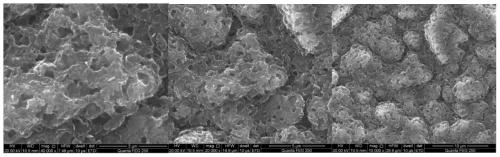

[0053] Step 2, nickel layer sputtering. The method is to use physical magnetron sputtering equipment, under the pressure of 0.5-2 Pa, use a high-purity nickel target with a purity of 99.99%, uniformly sputter a layer of nickel film on the diamond film in step 1, and the sputtering power is 50- 150 watts, the nickel layer thickness is 5-50nm.

[00...

Embodiment 2

[0060] Step 1. Preparation of boron-doped diamond film. First place the silicon wafer substrate in an acetone solution and ultrasonically clean it for 10 minutes to remove surface oil stains; then ultrasonically clean it in deionized water for 15 minutes, dry it in a drying oven and put it into a chemical vapor deposition chamber for boron-doped diamond growth , the number of turns of the hot wire during the growth process is 15 turns, the temperature of the hot wire is controlled at 2250°C, the surface temperature of the substrate is 800°C, the gas ratio is methane / borane / hydrogen equal to 1 / 49 / 0.3, and the chamber pressure is about 3.0 thousand Pa, the grain size of the grown diamond film is 6-8 microns in diameter, and the film thickness ranges from 10-15 microns.

[0061] Step 2, nickel layer sputtering. The method is to use physical magnetron sputtering equipment, under the pressure of 1 Pa, use a high-purity nickel target with a purity of 99.99%, uniformly sputter a lay...

Embodiment 3

[0067] Step 1. Preparation of boron-doped diamond film. First place the silicon wafer substrate in an acetone solution and ultrasonically clean it for 10 minutes to remove surface oil stains; then ultrasonically clean it in deionized water for 15 minutes, dry it in a drying oven and put it into a chemical vapor deposition chamber for boron-doped diamond growth , the number of turns of the hot wire during the growth process is 15 turns, the temperature of the hot wire is controlled at 2250°C, the surface temperature of the substrate is 800°C, the gas ratio is methane / borane / hydrogen equal to 1 / 49 / 0.3, and the chamber pressure is about 3.0 thousand Pa, the grain size of the grown diamond film is 6-8 microns in diameter, and the film thickness ranges from 10-15 microns.

[0068] Step 2, nickel layer sputtering. The method is to use physical magnetron sputtering equipment, under the pressure of 1 Pa, use a high-purity nickel target with a purity of 99.99%, uniformly sputter a lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com