Atomic-scale iron active site catalyst as well as preparation method and application thereof

An active site, atomic-level technology, applied in the field of nanomaterials, can solve the problems of atomic agglomeration, reduce the catalytic activity of metal active sites, etc., to accelerate the mass transfer rate, improve the catalytic activity and cycle stability, and achieve high stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

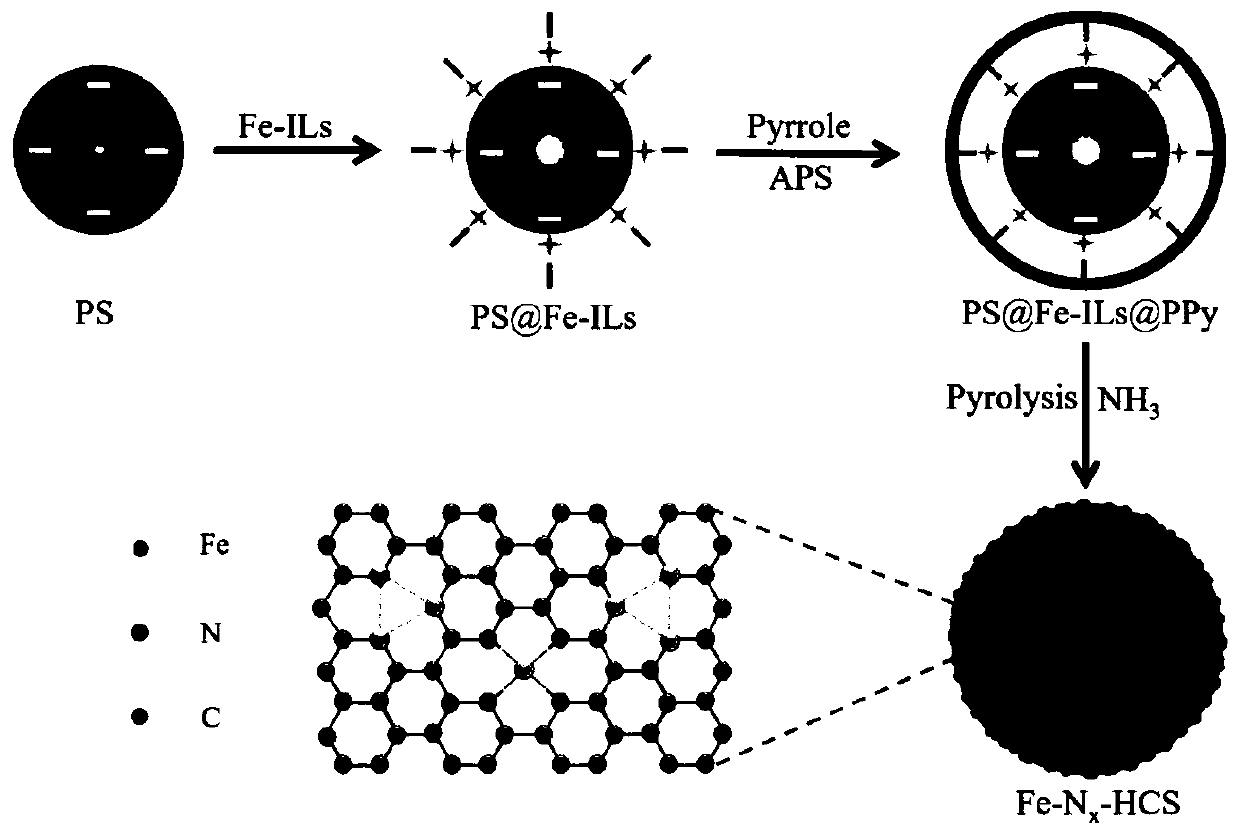

[0025] The present invention also provides a method for preparing the above-mentioned atomic-level iron active site catalyst, comprising the following steps:

[0026] 1) Add 1-butyl-2-methylimidazolium bromide to the dispersion of silver ferricyanide, add deionized water and centrifuge to separate the lower layer product and disperse it in deionized water to obtain ferricyanide dimethylimidazole ionic liquid;

[0027] 2) Disperse the polystyrene nanosphere suspension and the ferricyanide dimethylimidazolium ionic liquid obtained in step 1) into deionized water to obtain the first mixed solution, then add pyrrole monomer to obtain the second mixed solution, add Ammonium persulfate solution, react for 5-7 hours, and then wash and dry the product obtained from the reaction to obtain a core-shell structure precursor with evenly dispersed iron ions;

[0028] 3) In an ammonia atmosphere, heat the core-shell structure precursor obtained in step 2) to 750-850° C. for 1.5-2.5 hours of...

Embodiment 1

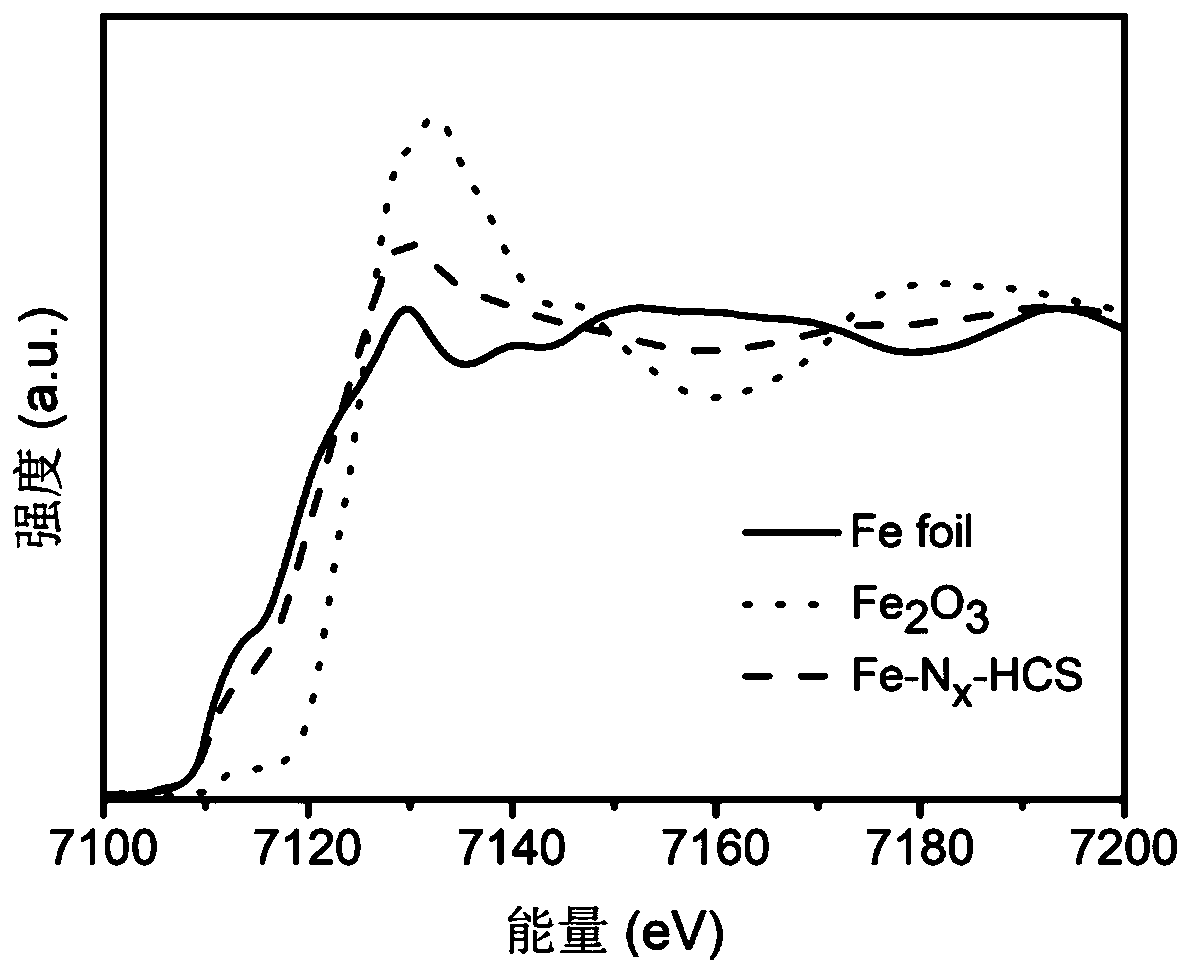

[0035] This embodiment provides an atomic-level iron active site catalyst, and the preparation method is as follows:

[0036] (1) Synthesis of iron-containing ionic liquid: 0.128g of 1-butyl-2-methylimidazolium bromide (28mmol) was slowly added to 50mL of silver ferricyanide (10mmol) dispersion with a concentration of 0.2mol / L under stirring , centrifuged 3 times with deionized water and got 0.5g of the lower layer product, redispersed into 10mL of deionized water; to obtain a concentration of 0.5g / mL ferricyanide dimethyl imidazolium ionic liquid (Fe-ILs);

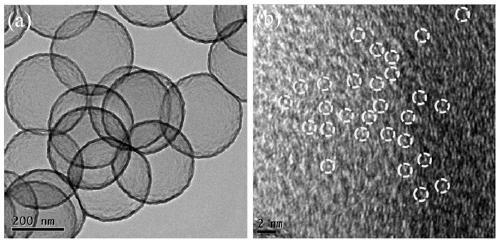

[0037] (2) Constructing a core-shell structure precursor with uniformly dispersed iron ions: Fe-ILs (4mL, 0.5g mL -1 ) and polystyrene (PS) nanosphere suspension (2mL, 0.1g mL -1 ) was dispersed into 100mL deionized water under vigorous stirring, and the stirring was continued for 10 min to obtain the first mixed solution PS@Fe-ILs, 0.4 mL of pyrrole monomer (pyrrole) was added, and the stirring was continued for 10 min to...

Embodiment 2

[0041] This embodiment provides an atomic level iron active site catalyst (Fe-N x - the preparation method of HCS-18), according to step (1) in embodiment 1, prepare ferricyanogen dimethyl imidazolium ionic liquid (Fe-IL), then 0.4mL pyrrole monomer in embodiment 1 step (2) Change to 0.6mL pyrrole monomer, then prepare Fe-N according to embodiment 1 step (3) x - HCS-18 (the number 18 indicates that the hollow carbon nanospheres have an average carbon shell thickness of 18 nm).

[0042] The content of iron active sites in the catalyst of this example was measured by an inductively coupled plasma mass spectrometer to be 1.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com