Method for extracting carbon source from kitchen solid residues through enzymic method

An enzymatic extraction and cooking technology, applied in chemical instruments and methods, solid waste removal, special compound water treatment, etc., can solve problems such as environmental hazards, poor system stability, toxic and harmful substances, etc. The effect of alleviating short supply and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

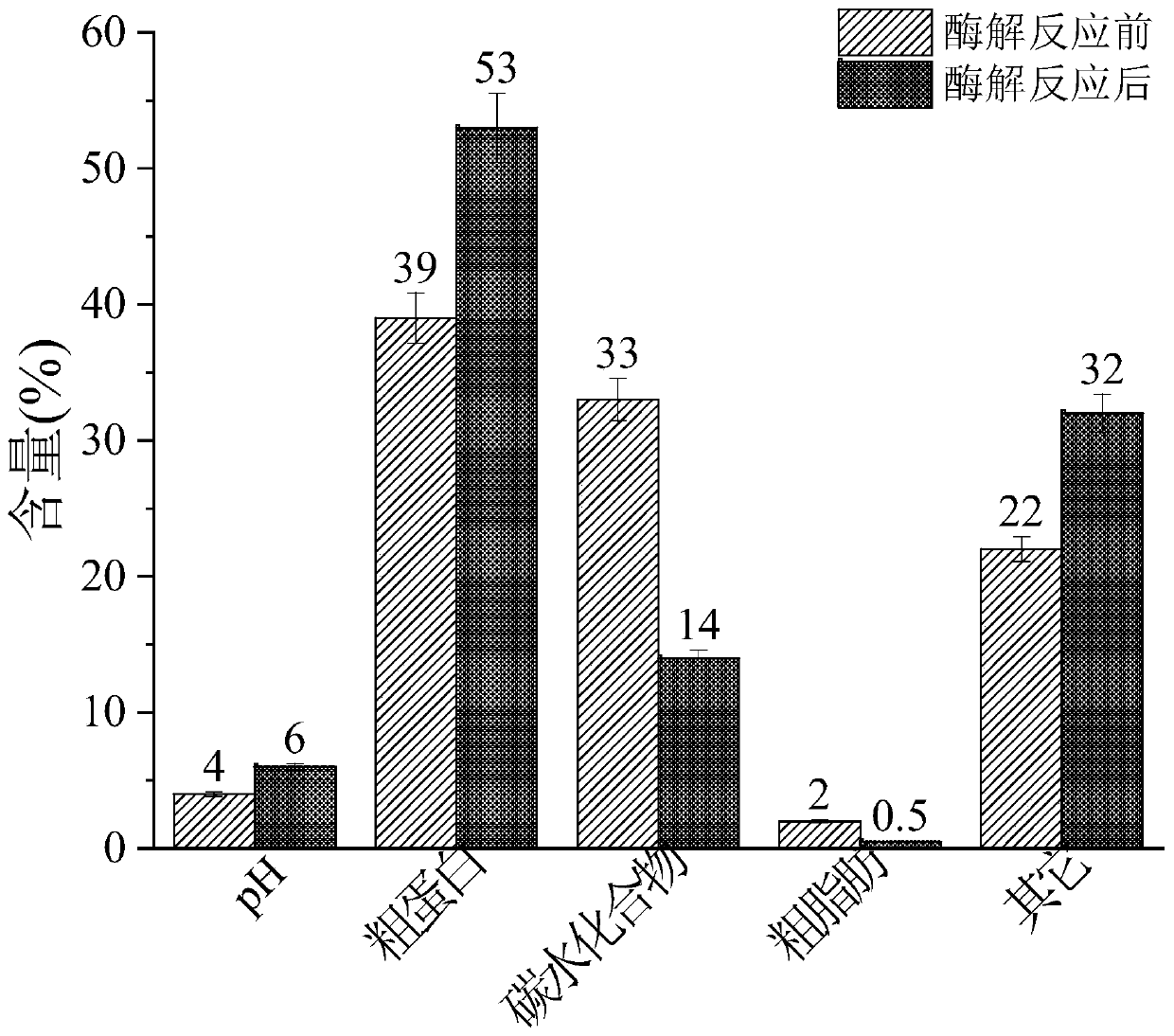

[0052] Analyze the composition of the food solid residue raw material (the solid residue obtained from a company in Zhangjiagang after mechanical sorting, pulping, three-phase separation and other pretreatments). The solid residue is mainly composed of crude protein, carbohydrates, and crude fat and other impurities, and other impurities are mainly crude fibers, as shown in Table 1 below:

[0053] Table 1 The main components of the kitchen (g / 100g dry weight)

[0054]

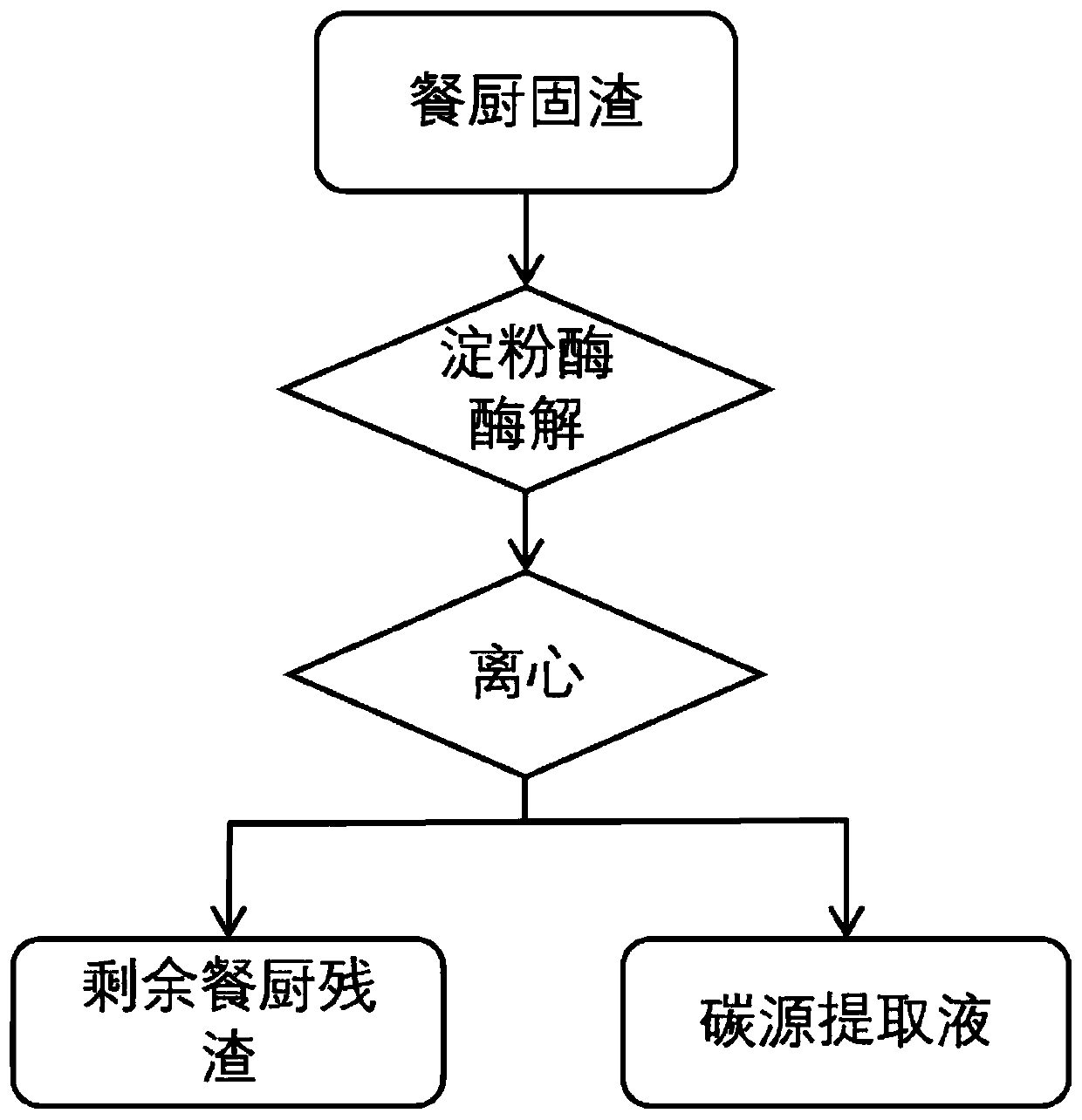

[0055] A kind of method (as figure 1 shown), including the following steps:

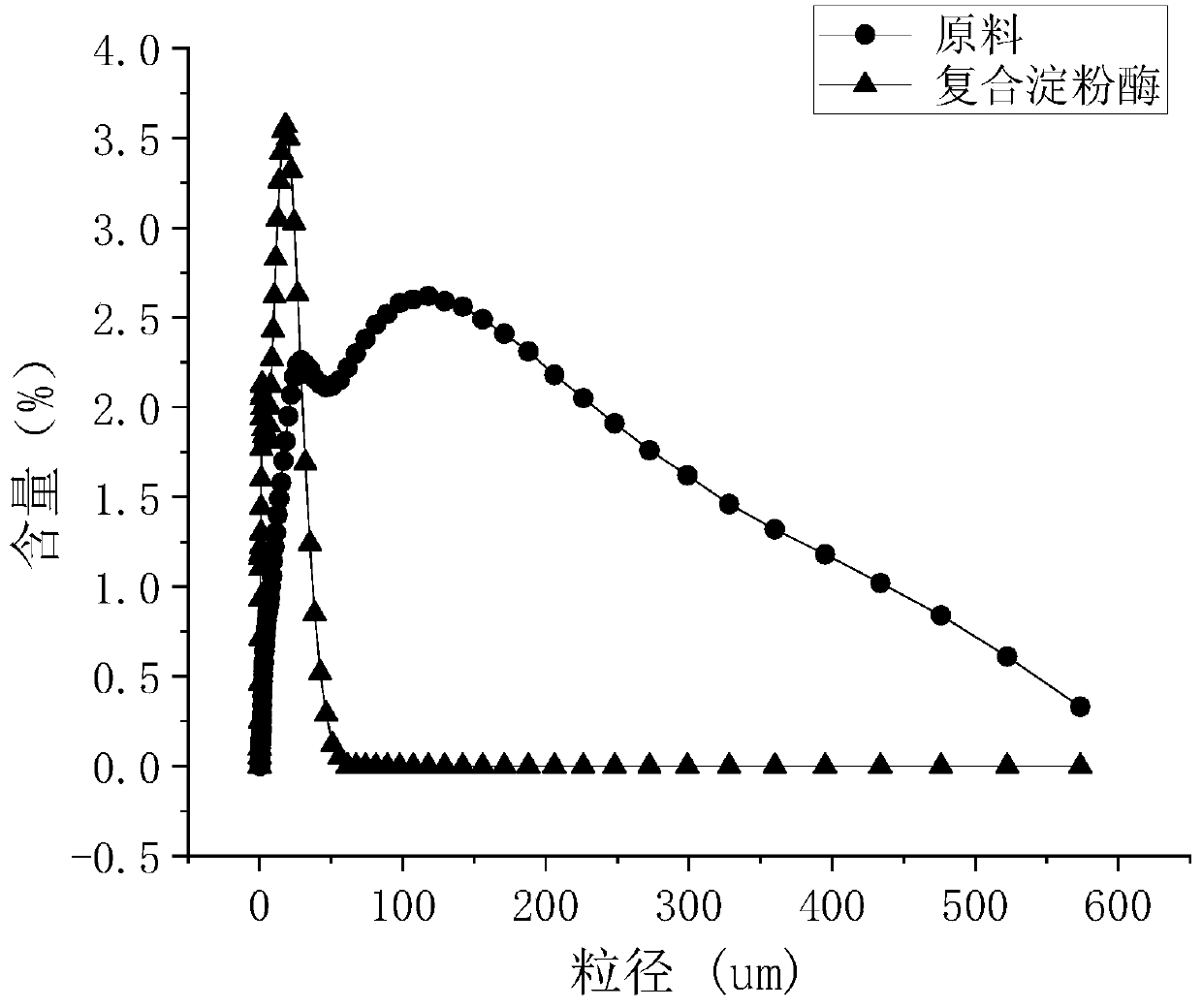

[0056] (1) Pretreatment: Take the kitchen solid slag raw material and put it into a mortar for grinding for about 5 minutes. After grinding and crushing, the average particle size of the kitchen solid slag is about 99.19 μm; Seal it with a parafilm, place it in a 120°C high-temperature sterilization pot for 20 minutes, and obtain sterilized kitchen solid residue;

[0057] (2) Regulating the moisture content of the kitchen solid ...

Embodiment 2

[0065] The optimization of the ratio of embodiment 2 enzymes

[0066] Adjust the mass ratio of the medium-temperature α-amylase and amyloglucosidase in Example 1 as shown in Table 2, and keep other parameters consistent with Example 1 to obtain a carbon source extract. The obtained carbon source extract is subjected to a performance test, and the test results are shown in Table 2:

[0067] Table 2 The performance test of the carbon source extract obtained by the mass ratio of different mesophilic α-amylase and amyloglucosidase

[0068]

Embodiment 3

[0069] The optimization of embodiment 3 pH

[0070] Adjust the pH of Example 1 as shown in Table 3, and keep the other parameters consistent with Example 1 to obtain a carbon source extract. The obtained carbon source extract is subjected to a performance test, and the test results are shown in Table 3:

[0071] The performance test of the carbon source extract solution that table 3 different pH obtains

[0072]

[0073]

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com