Enamel composition, method for preparing enamel composition, and cooking appliance

A composition and enamel technology, applied in the direction of kitchen utensils, home utensils, special materials for cooking utensils, etc., can solve the problems of reduced durability of enamel compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] Preparation method of enamel composition

[0024] The method 100 for preparing the enamel composition according to the embodiment may include: providing the above-mentioned material for the enamel composition (110); melting the material (120); and quenching the melted material (130), thereby forming the enamel composition.

[0025] The materials can be mixed well and then melted. The material can melt in the temperature range of 1200°C to 1400°C. Alternatively, the material may be melted for 1 to 2 hours. The molten material can then be rapidly cooled by a cooler such as a chill roll.

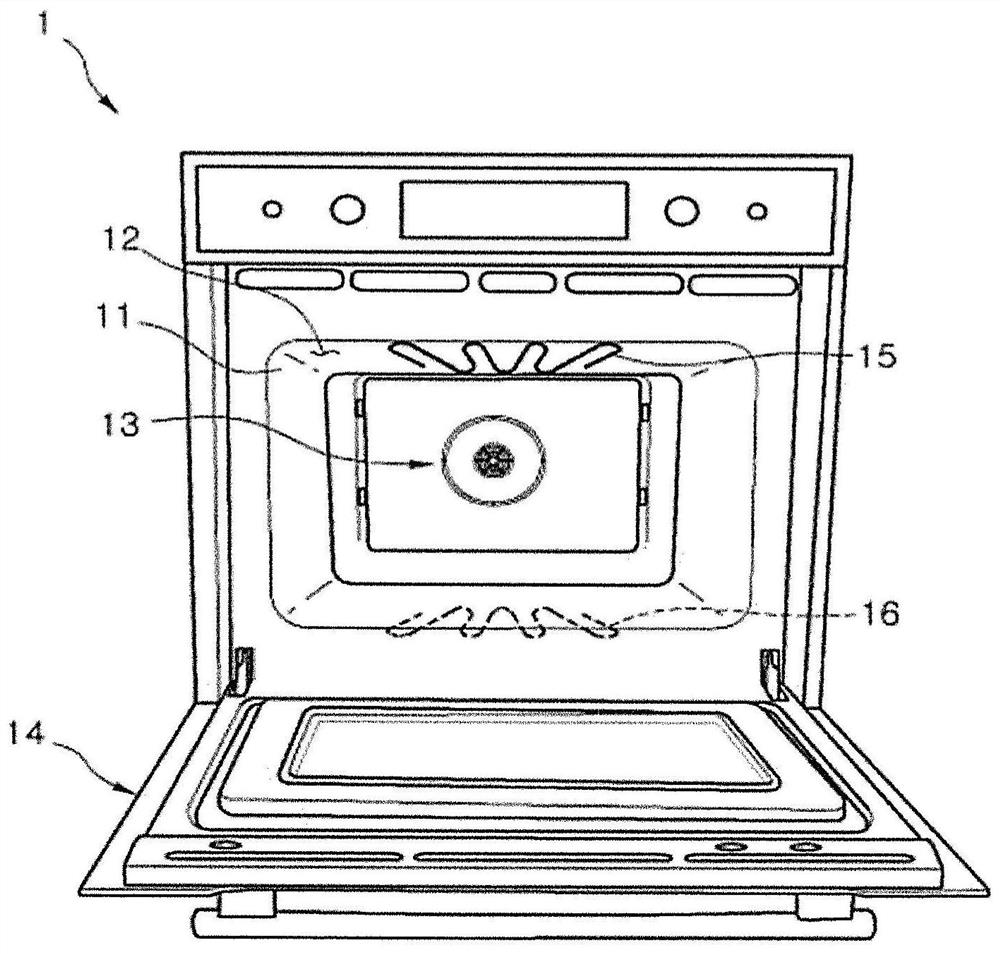

[0026] cooking utensils

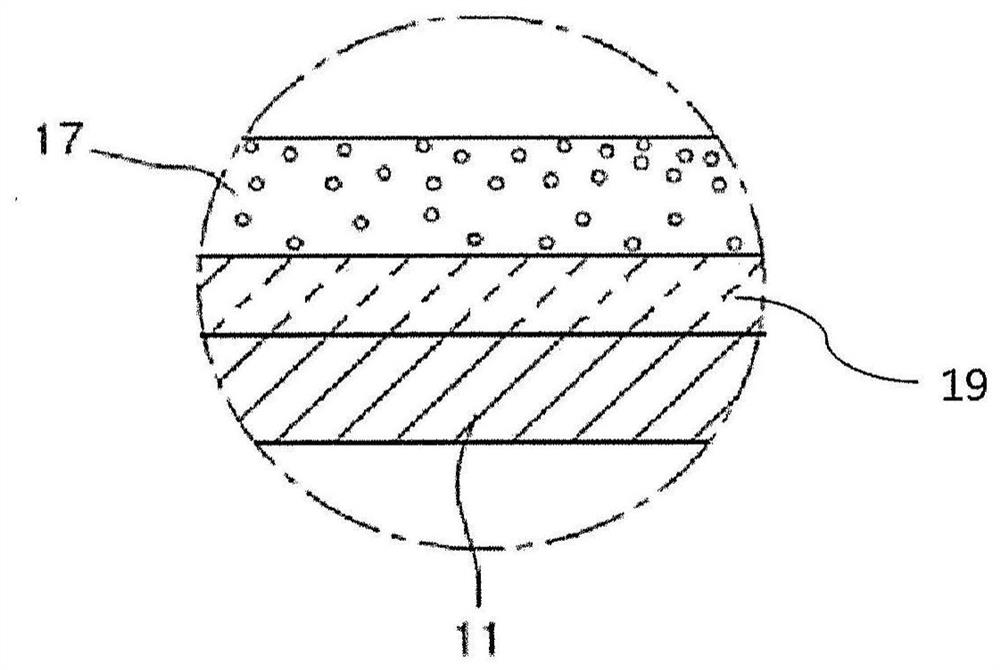

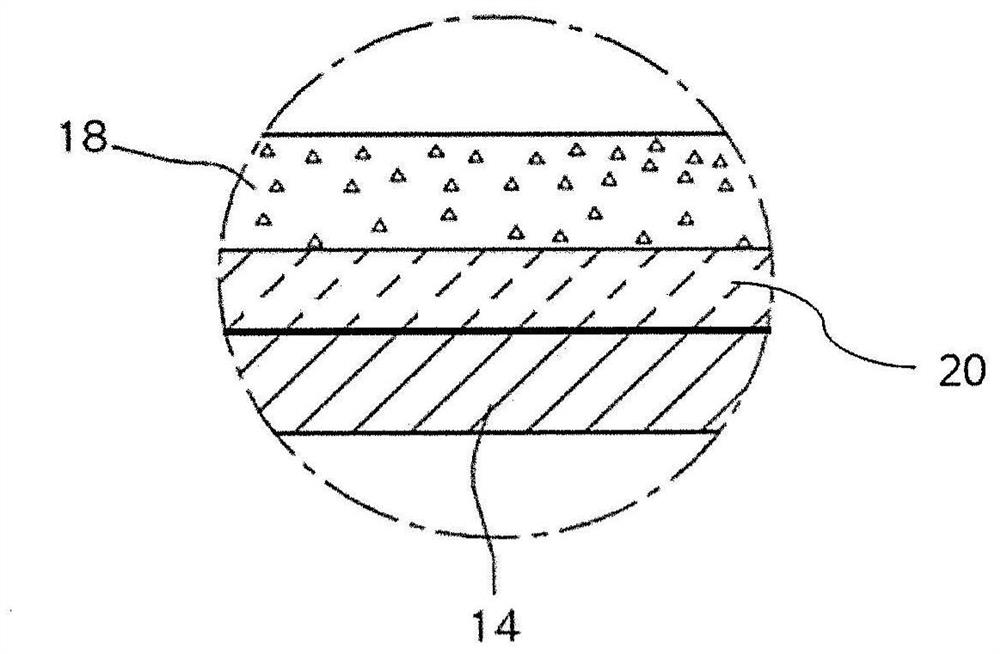

[0027] The enamel composition of the embodiments may be coated on the surface of a target object. For example, the target object could be all or part of a metal plate, glass plate, or cooking utensil. For example, the enamel composition may be coated on the inner surface of the cavity of the cooker or the inner surface of the door of the cooker.

[0028]...

Embodiment

[0036] Preparation method of enamel composition

[0037] Enamel compositions having the composition ratios described in Table 1 below were prepared. The raw materials of the various components were thoroughly mixed in a V-blender for 3 hours. Ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) used as P 2 o 5 raw materials. Sodium carbonate (Na 2 CO 3 ), potassium carbonate (K 2 CO 3 ) and lithium carbonate (Li 2 CO 3 ) respectively used as Na 2 O, K 2 O and Li 2 O raw material. The mixed material was fully melted at 1300°C for 1.5 hours and rapidly cooled in a chill roll. Then get glass shards.

[0038] In order to produce molten material (powder), use a ball mill to control the initial particle size of the glass chips obtained through the above process, use a jet mill to grind for about 5 hours, and then pass through a 325-mesh sieve (ASTM C285-88) to make the particle size of the glass chips Limit below 45 μm.

[0039] Table 1

[0040]

[0041] Prepara...

experiment example

[0047] The properties of the samples of the above-mentioned Examples and Comparative Examples were evaluated as follows. Table 3 shows the results.

[0048] 1. Cleaning performance against chicken fat as soil

[0049] 1 gram of chicken fat was evenly and thinly applied with a brush on the surface of the sample in which the enamel composition was coated on a metal substrate (100×100 (mm)) as a soil. Then, the soil-applied sample was placed in a thermostat, and the soil was fixed at a temperature ranging from 250°C to 290°C for 1 hour. After fixing the dirt, the samples were cooled naturally and burned at a temperature of 350°C for 1 hour. Then, the hardened dirt was cleaned with a kitchen brush using a frying pan moistened with room temperature water with a force of 3 kgf or less. The cleaned part of the contaminated surface of the sample was homogenized using a rod with a flat bottom and a diameter of 5 cm.

[0050] 2. Cleaning performance on Monster Mash

[0051] The cle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com