Ternary composite phase-change thermal-insulation foam building material and preparation method thereof

A building material and ternary composite technology, applied in ceramic products, other household appliances, applications, etc., can solve the problems of low storage capacity of phase change materials, reduced service life of building materials, low mechanical strength of building materials, etc., and achieve the suppression of liquid phase leakage , Improve the porosity and specific surface area, and solve the effect of liquid phase leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

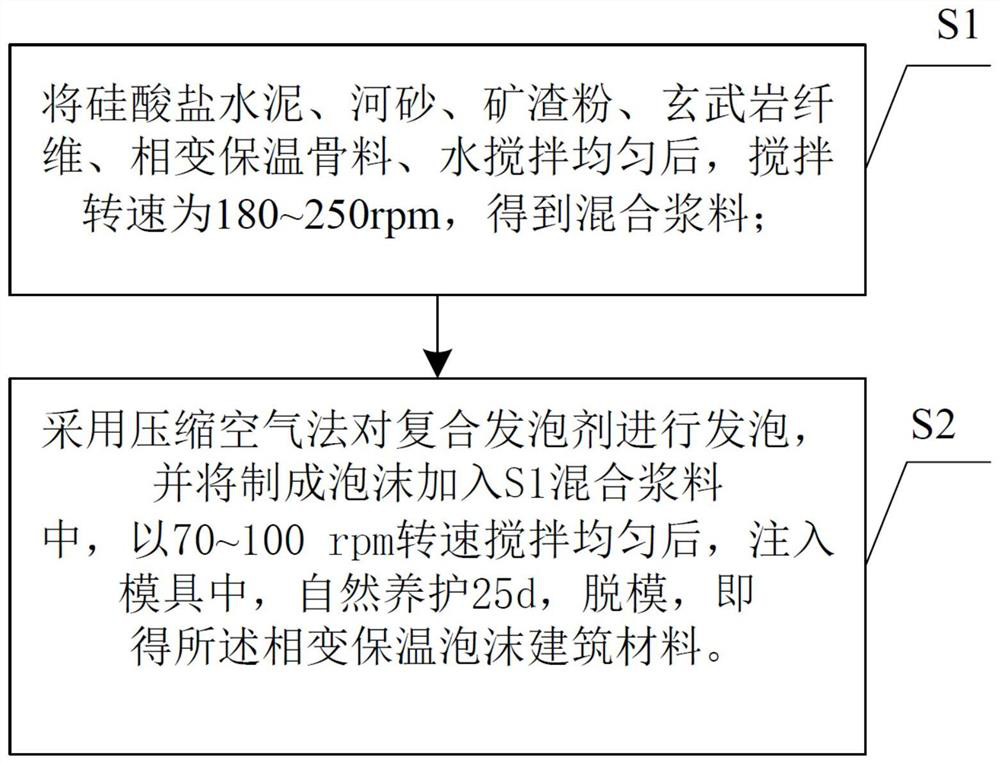

Method used

Image

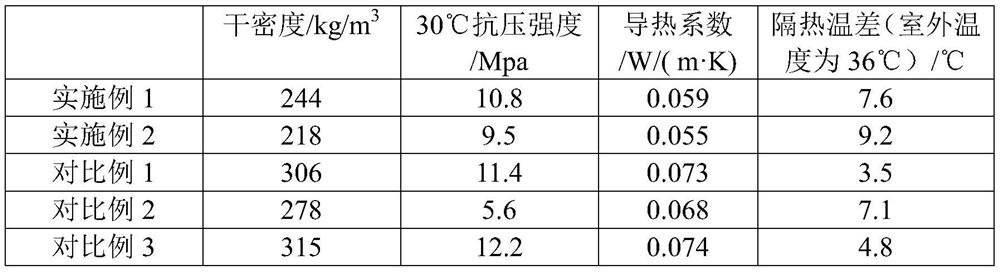

Examples

Embodiment 1

[0025] Example 1 Preparation of ternary composite phase change thermal insulation foam building material

[0026] A. Preparation of phase change thermal insulation aggregate:

[0027] a1. Modification of silica airgel: immerse silica airgel in a mixed acid containing 0.05mol / L HF and 0.3mol / L HCl, stir and activate for 1h, filter, and dry at 120°C for 12h to evaporate the HF and HCl, then add 3-aminopropyltrimethoxysilane, stir and modify for 0.5h to obtain modified silica airgel; silica airgel, mixed acid, 3-aminopropyltrimethoxysilane The dosage ratio is 1g: 3mL: 0.1mL;

[0028] b1. Preparation of phase-change thermal insulation aggregate: heat and melt capric acid, palmitic acid, and dodecyl alcohol at 65°C, stir evenly, add modified silica airgel, and heat in an environment with a vacuum degree of 0.04MPa and a temperature of 30°C Under ambient conditions, stir and adsorb for 1 hour, then cool and crystallize at 15°C for 2 hours, stir continuously during the crystallizat...

Embodiment 2

[0035] Example 2 Preparation of ternary composite phase change thermal insulation foam building material

[0036] A. Preparation of phase change thermal insulation aggregate:

[0037] a1. Modification of silica airgel: immerse silica airgel in a mixed acid containing 0.15mol / L HF and 0.5mol / L HCl, stir and activate for 2h, filter, and dry at 120°C for 12h to evaporate the HF and HCl, then add γ-aminoethylaminopropyltrimethoxysilane, stir and modify for 0.5~1h to obtain modified silica airgel; silica airgel, mixed acid, γ-aminoethylammonia The dosage ratio of propyltrimethoxysilane is 1g: 6mL: 0.2mL;

[0038] b1. Preparation of phase-change thermal insulation aggregate: heat and melt capric acid, palmitic acid, and dodecyl alcohol at 70°C, stir evenly, add modified silica airgel, and heat in an environment with a vacuum degree of 0.07MPa and a temperature of 40°C Under ambient conditions, stir and adsorb for 2 hours, then cool and crystallize at 20°C for 6 hours, stir continu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com